- What is the meaning of FPCB?

- The structure of the FPCB flexible printed circuit board

- Cost of FPCB Flexible Printed Circuit Board

- The main performance of FPC flexible circuit board economy

- Summing up

What is the meaning of FPCB?

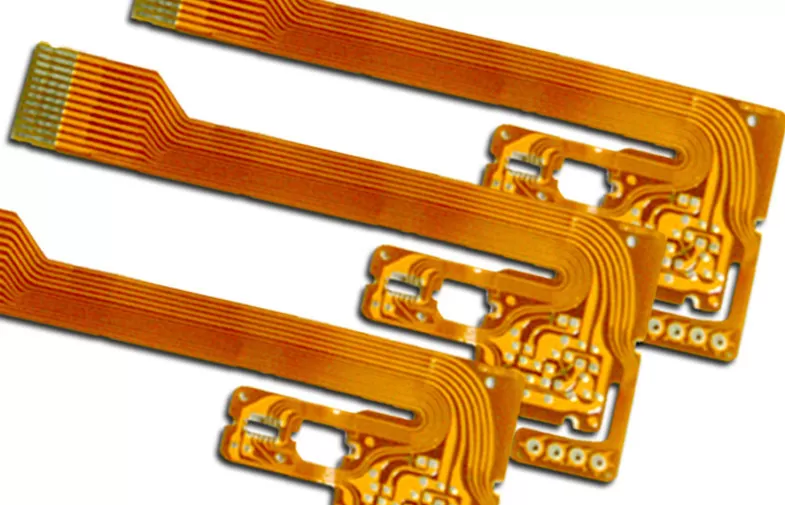

FPC has a variety of meanings; one refers to the flexible circuit board, and the English are “FPC PCB” or “FPCB, Flexible and Rigid-Flex.” It is a printed circuit board with graphics made from a flexible substrate consisting of an insulating substrate and a conductive layer. There can be a binder between the insulating substrate and the conductive layer. It is a printed circuit board made of polyimide or polyester film as a substrate with high reliability, excellent flexibility, and elasticity to change shape. Mainly used in military, defense, and consumer electronics such as digital cameras, watches, laptops, and other fields. The industry is called flexible board or FPC, with continuous automated production, high wiring density, lightweight, small size, fewer wiring errors, and thin thickness.

The structure of the FPCB flexible printed circuit board

The structural parts of FPCB flexible printed circuit boards. They consist of wires formed by gluing copper foil on an insulating substrate (film), using an overlay or a special layer to protect the copper foil from exposure to corrosive substances.

Insulating films

FPCB flexible printed circuit boards use a flexible laminate. The performance of the laminate is important not only for its production process but also for the performance of the completed circuit. Flexible laminate consists of conductive foo and insulating substrate; there are two types of insulating substrate applied in FPCB flexible printed circuit board:

1 ) thermosetting plastics: there are polyimide, sodium polyacrylate, etc.

2) Thermoplastics: after processing, the material will soften when exposed to heat, such as some polyvinyl film types, fluoride, polymer, etc.

The insulating film forms the base layer of the circuit, and the adhesive bonds the copper foil to the insulating layer. In multilayer designs, it is then bonded to the inner layer. They are also used as protective coverings to insulate the circuit from dust and moisture and to reduce stress during flexing, and the copper foil forms the conductive layer. In some FPCB flexible circuits, rigid members formed from aluminum or stainless steel are used, which provide dimensional stability, physical support for the placement of components and wires, and stress relief. An adhesive bonds the rigid members to the FPCB flex circuit. Another material that is sometimes used in FPCB flex circuits is the adhesive laminate, which is formed by coating both sides of an insulating film with an adhesive. Bonding laminates provide:

- Environmental protection and electrical insulation.

- The ability to eliminate a layer of film.

- The ability to bond multiple layers with fewer layers.

Adhesives

In addition to being used for bonding insulating films to conductive materials, the adhesive is also used as a cover layer, as a protective coating, and as an overlay coating. The main difference between the two is the application method used, with overlay bonding covering the insulating film to form a circuit in a laminated configuration. The screen printing technique used for the adhesive overlay coating.

Not all laminated structures contain adhesive, and laminates without adhesive form thinner circuits and greater flexibility. It has better thermal conductivity compared to adhesive-based laminate structures. The thin structure of adhesive-free FPCB flex circuits and the improved thermal conductivity due to the elimination of the thermal resistance of the adhesive makes it possible to use it in operating environments where adhesive-based laminated structures of FPCB flex circuits cannot be used.

Conductor

Copper foil is suitable for use in FPCB flexible circuits, either electrodeposited (ED) or plated. One side of the electrodeposited copper foil has a glossy surface, while the other is processed with a dull, non-glossy surface. It is a flexible material and can be made in many thicknesses and widths. The non-glossy side of ED copper foil is often specially treated to improve its bonding ability. In addition to flexibility, wrought copper foil is also hard and smooth, making it suitable for dynamic flexing applications.

Cost of FPCB Flexible Printed Circuit Board

The price of FPCB flexible assembly is decreasing and becoming close to the traditional rigid circuit. The main reason for this is the introduction of newer materials, improved production processes, and changes in structure. The structure now allows for a more thermally stable product with few material mismatches. Some of the newer materials allow for more precise lines due to thinner copper layers, making the components lighter and more suitable for fitting into small spaces.

How to account for FPC flexible circuit board quotation?

1) Board cost (the cost is different for different boards)

2) Drilling cost (the number of holes and the size of the hole diameter affects the drilling cost)

(3) process costs (different process requirements of the board lead to different process difficulties, so that the price will be different).

(4) labor, water, and electricity plus processing costs (this cost depends on the cost control of each factory, relatively speaking, the Taiwan factory is much lower).

Plate material affects the price of the following main points.

(1) plate material: FR-4, CEM-3, which is our common double-sided and multilayer plate, price is also related to the thickness of the plate and the thickness of copper platinum in the center of the plate, while FR-I, CEM-1 are our common single panel material, and the price of this material is also very different than the above double-sided, multilayer plate.

(2) is the thickness of the plate: the thickness of our common is: 0.4, 0.6, 0.8, 1.0, 1.2, 1.5, 1.6, 2.0, 2.4, 3.0, 3.4, and the thickness of our customary plate price difference is not very large.

(3) copper platinum thickness: copper platinum thickness is generally divided into 18 (2/1OZ), 35 (1OZ), 70 (2OZ), 105 (3OZ), 140 (4OZ), etc.

Process cost

(1) Depending on the FPC flexible circuit board above the line, such as the line dense line thin (in 4/4mm) below, the price will be another calculation.

(2) there is a BGA on the board, so the cost will also be relatively higher; some local BGA is another calculation of how much a.

(3) Depending on what appearance treatment process we commonly have: spray lead-tin (hot air leveling), OSP (environmental board), spray pure tin, tin, silver, gold, etc., of course, different appearance processes, the price will be different.

(4) also depends on the process specifications; we commonly use: IPC2 level, but there are customer requirements that will be higher (such as Japanese); we commonly have: IPC2, IPC3, enterprise standards, military standards, etc., of course, the higher the specification, the higher the price will be.

The FPC flexible circuit board industry sells each piece of FPC flexible circuit board customized. Therefore, the FPC flexible circuit board board board quotation needs to first cost accounting, together with the need to refer to the FPC flexible circuit board accounting machine active spelling accounting, in the standard scale of the laminate layout of the material utilization rate to make a comprehensive offer.

FPC flexible circuit board industry costing is the most special, the messiest of all industries, from the opening, pressing, and forming, all the way to FQC, packaging, completion of storage, according to the need for each process input material costs, labor costs, production costs and other step-by-step accounting, and then according to the order product number batch accumulation of costs. And the process’s normative rate will differ for different types of products. For some products, such as blind, buried hole plates, sinker plates, and pressed copper seat plates, it is necessary to choose some special accounting methods for this because of the process or the special nature of all materials. Similarly, the drilling process used to drill the nozzle size will also affect the cost of the product, which directly affects the WIP cost, scrap cost of accounting, and evaluation.

In addition, FPC flexible circuit board factory is attributed to OEM customers’ OEM products; different customers’ custom products are not the same, and there are few shared products. On the other hand, for quality considerations, some customers may also specify using a manufacturer’s substrate, ink, etc., to achieve it’s quality and cost control requirements.

The main performance of FPC flexible circuit board economy

If the circuit design of FPCB is relatively simple, the total volume is not large, and the space is suitable, the traditional internal connection method is much cheaper. If the circuit is complex, processing many signals, or has special electrical or mechanical performance requirements, FPC flexible circuit board is a better design choice. The flexible assembly method is the most economical when the application’s size and performance exceed a rigid circuit’s capability. FPC flex circuit boards with 12 mil pads with 5 mils through holes inside and 3 mil lines and spacing can be made on a single film. Therefore, it is more reliable to mount the chip directly on the film. Because it does not contain flame retardants that may be a source of ionic drill contamination, these films may be protective and cured at higher temperatures to get a higher glass transition temperature. The cost savings of flexible materials compared to rigid materials is due to the elimination of connectors.

The high cost of raw materials is the main reason for the high price of FPC flexible circuit boards. The price of raw materials varies widely, with the lowest cost polyester FPC flexible circuit board used in raw materials being 1.5 times the cost of raw materials used in rigid circuits; high-performance polyimide FPC flexible circuit board is up to four times or more. At the same time, the material’s flexibility makes it difficult to automate processing during manufacturing, resulting in lower yields; the final assembly process is prone to defects, including peeling off flex attachments and line breakage. Such conditions are more likely to occur when the design is unsuitable for the application. Under high stresses caused by bending or forming, the choice of reinforcing or strengthening materials is often required. Despite its high raw material cost and manufacturing hassles, the foldable, bendable, and multilayer assembly board features will reduce overall assembly size and a subsequent reduction in materials used, resulting in a lower total assembly cost.

The FPC flexible circuit board industry is amid small-scale but rapid development. The polymer thick film method is an efficient, low-cost production process. This process selectively screens conductive polymer inks on inexpensive, flexible substrates. The representative flexible substrate is PET. Polymer thick film conductors include screen-printed metal fillers or toner fillers. The polymer thick film method is inherently clean, uses lead-free SMT adhesives, and does not require etching. Because it uses an additive process and low substrate cost, a polymer thick film circuit is 1/10 of the copper polyimide film circuit; 1/2 to 1/3 of the price of rigid circuit boards. The polymer thick film method is particularly suitable for device control panels. In cell phones and other portable products, the thick polymer film is suitable for converting components, switches, and lighting devices on printed circuit boards to polymer thick film circuits. It saves cost and reduces energy consumption at the same time.

Generally speaking, FPC flexible circuit boards cost more than rigid circuits in terms of expense and higher cost. When manufacturing flexible boards, in many cases have to face the fact that many of the parameters are out of tolerance. The difficulty of manufacturing FPC flexible circuit boards lies in the material’s flexibility.

Summing up

In the coming years, smaller, more complex, and more expensive to assemble flexible circuits will require more novel methods of assembly and the need to add hybrid flexible circuits. The challenge for the flexible circuit industry is to take advantage of its technology and keep pace with the demands of computers, telecommunication, consumer needs, and dynamic markets. In addition, flexible circuits will play an important role in the lead-free initiative. Flexible PCBs are ideal for building compact packages and devices because of their bending characteristics. Market requirements for FPCB’s ultra-thinness, flexibility, wire diameter, component placement, etc., continue to rise; FPCB industry technology still needs to be upgraded to meet the development needs of downstream smartphones, wearable devices, and other industries with high functional integration, ultra-thinness, and miniaturization. FPCB is an important component indispensable to developing the electronic information industry. It is a kind of PCB, and its flexible performance is superior, more in line with the electronic products Technology upgrading needs, with good prospects for development.

Apollo is a professional R & D design, copy board, development, and production of printed circuit boards (PCB), flexible circuit boards (FPC) flexible and rigid (FPCB), impedance and high-frequency control high accuracy buried blind hole (HDI), super-large ultra-long ultra-thin, aluminum-based and special dielectric materials high-tech enterprises. If your project requires this type of circuit board, please get in touch with us for more details about FPC and to get a free quote for your design.