- Overview of printed circuit board assembly services

- Steps for assembling a printed circuit board.

- Advantages of PCBA OEM mode

- 1、Reduce the process and reduce enterprise management costs.

- 2, procurement channel advantages, reduce procurement costs.

- 3、Perfect quality management system, product quality can be guaranteed.

- 4、The whole process is customer-led and more discourse.

- 5、Provide process optimization program.

- 6, perfect after-sales service.

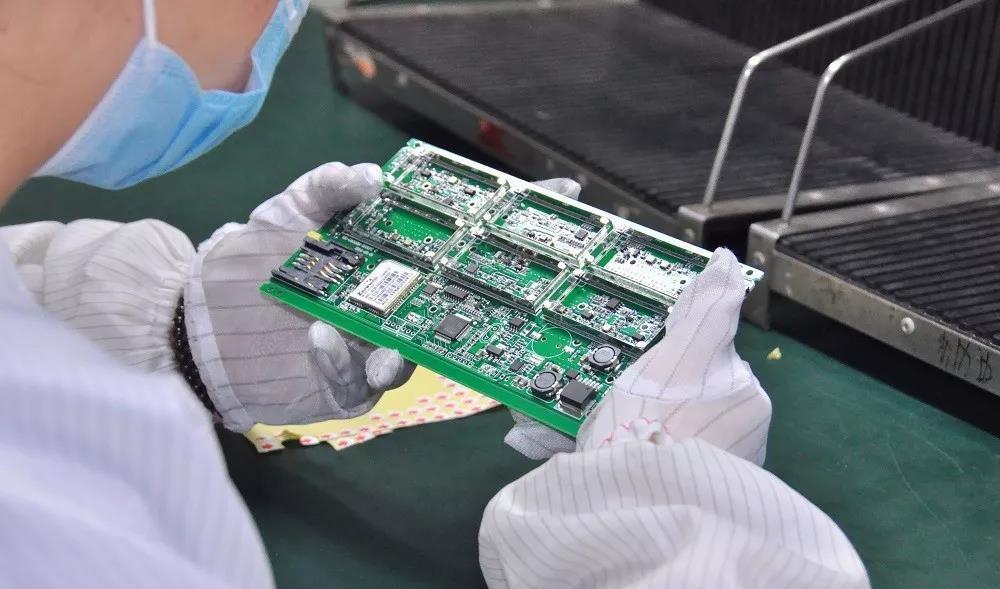

Before we understand the advantages of the PCB foundry standby model, let’s link to what types of printed circuit board assembly services are available and what specific services are available. The printed circuit board (PCB) assembly or manufacturing process includes many steps. All these steps should go hand in hand to achieve a good PCB assembly (PCBA). One step must work in synergy with the previous one. In addition, the input should receive feedback from the output, making it easier to track and resolve any errors at an early stage. What are the steps involved in the PCB assembly process?

Overview of printed circuit board assembly services

Printed circuit board (PCB) assembly services must be performed carefully and meticulously. PCBs are used in various industrial and domestic applications; how electronic devices work depends on how well the board is assembled. The tightly woven structure consists of components such as copper foil, metal plates, epoxy resin, and glass fiber, which should perform when the assembly meets the requirements.

Depending on the design of the circuit board, the components involved, and the availability of materials, you can choose one of the following services.

- the electrical assembly of PCBs

- Mechanical assembly of PCBs

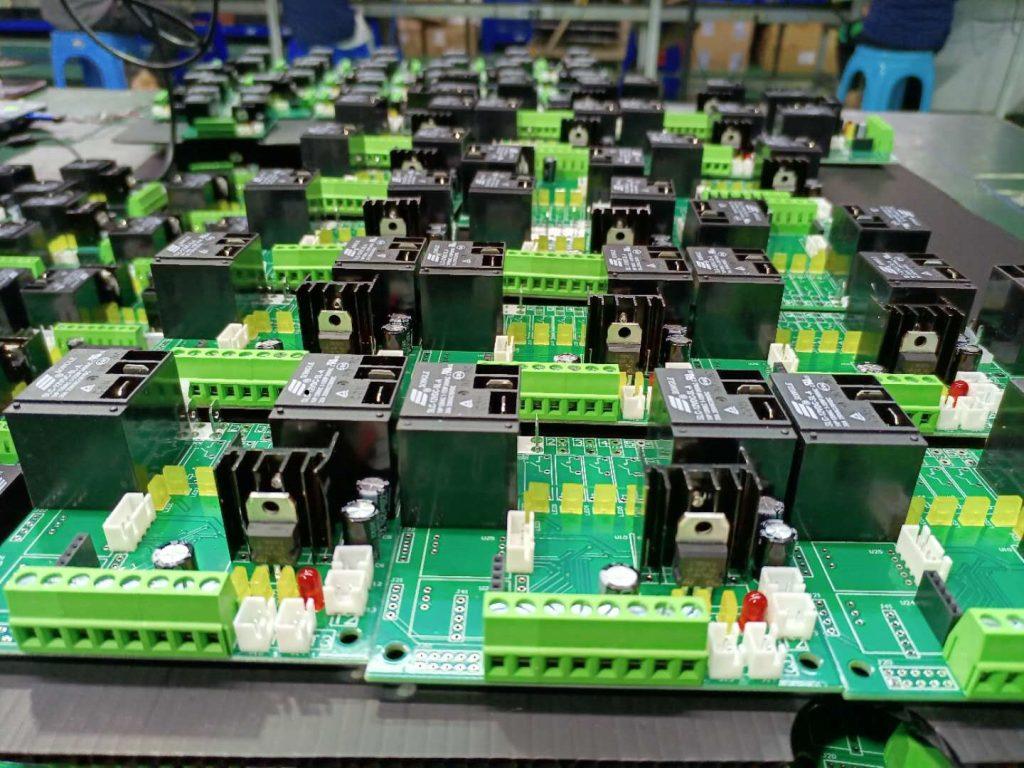

Steps for assembling a printed circuit board.

To perform a successful PCB assembly, you must follow some basic steps.

1. Complete the circuit board design according to your design and drill holes in the basic positions of the metal board (wear a dust cover to avoid any toxic metal dust or small particles).

2. Lay the board’s components perfectly according to your PCB design.

3. Adjust the polarity of the components for positive and negative polarity separately.

4. Solder the components to the board to hold them firmly in their respective positions. Use tin or lead solder to secure the components to the board.

5. After the bulky parts are soldered, pick the tiny parts with tweezers and fix them in their respective positions on the board with the help of adhesive/epoxy.

6. Thoroughly check the ends of the assembled printed circuit board for loose or unconnected components.

7. With the help of a multimeter, check the circuit board for connection problems.

8. If there are any defects, remove the solder of the faulty component, repair it, and then solder it back for final assembly.

9. After the PCB is fully assembled, install it in its permanent position.

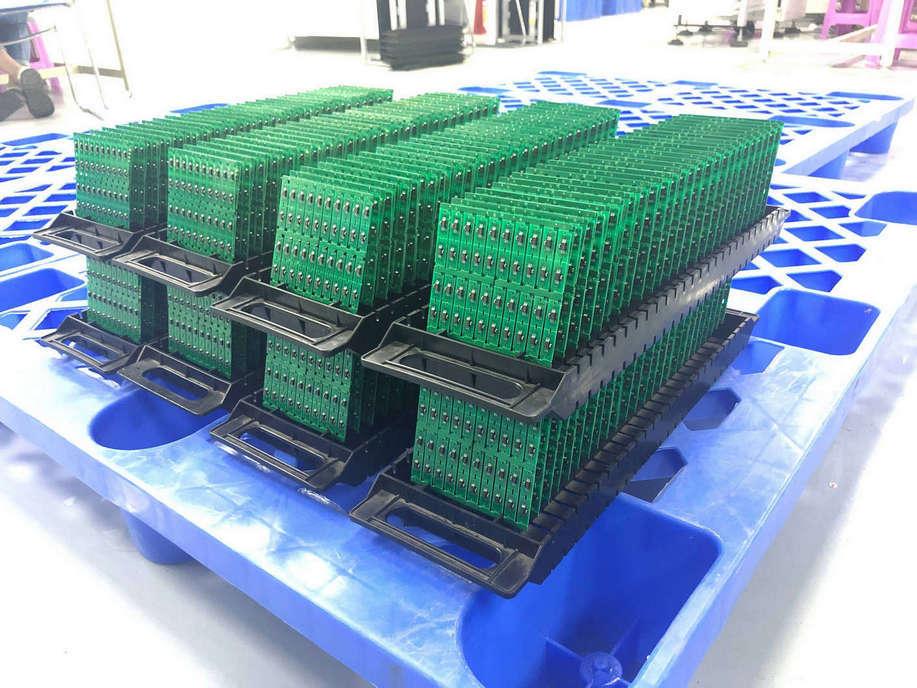

Advantages of PCBA OEM mode

PCBA OEM mode is now a development direction of the electronics manufacturing and processing industry, and the traditional SMT material processing compared to the specific advantages, this article will give you a detailed analysis.

1、Reduce the process and reduce enterprise management costs.

In traditional mode, often electronic engineers design circuit diagrams, Gerber files, and BOM lists provided to the procurement department; the procurement department, according to the engineer, provides Gerber files and BOM lists to find the corresponding PCB board manufacturers and electronic material suppliers, and then find SMT chip processing factory for processing, the whole process is very complex and labor-intensive, if you choose PCBA OEM mode, you only need to send the Gerber file and BOM list to the PCBA processing plant can save the procurement costs, material management costs, employment costs, time costs, site costs. The process is also more convenient to manage.

2, procurement channel advantages, reduce procurement costs.

PCBA processing factories often have the advantage of centralized procurement, have their complete supply chain system, and a variety of materials, delivery, price, and quality are more secure. When necessary, you can stock up in advance to avoid the risk of stockouts and save time costs.

3、Perfect quality management system, product quality can be guaranteed.

PCBA factory has a perfect quality management system to control product quality, DFM manufacturability inspection, NPI new product introduction meeting, IQC incoming inspection, IPQC process inspection, FAI first inspection, and OQA factory inspection; these different stages of inspection play a decisive role in product quality assurance, early detection, early improvement, early resolution, at the same time, PCBA factory will also pass Obtain ISO9001:2015 quality management system certification, ISO13485 medical certification, IATF16949 certification, SGS certification, and other certificates to enhance the hard strength of the factory and better serve customers.

4、The whole process is customer-led and more discourse.

Compared with SMT material processing mode, PCBA OEM mode customer viscosity is higher; customers know clearly what kind of products they want and what functional testing needs to be done, so the whole process is customer-led; PCBA processing factory provides technical help so that there are customers have a stronger voice in the manufacturing plant, to enjoy a better delivery service.

5、Provide process optimization program.

PCBA OEM mode, PCBA processing factory can provide supporting DFM manufacturability check, PCBA test program, mass production process yield optimization program, and a series of support services, according to different customers to develop different optimization programs, provide testing advice, improve the product through rate, wholeheartedly for the sake of customers. And SMT chip processing mode will only think about how to complete the patch plug-in welding as soon as possible and will not consider the process optimization.

6, perfect after-sales service.

In the traditional SMT chip processing mode, the factory is only responsible for the quality of the SMD plug-in welding part, resulting in product sampling after the problem is difficult to troubleshoot, difficult to deal with, but in the PCBA OEM mode, generally have after-sales service, including fault diagnosis, maintenance, testing, design program modification feedback, etc., can better optimize the product and improve quality.

In general, PCBA OEM mode can effectively reduce the management cost of enterprises, reduce procurement expenditure and improve product quality. The company can focus on the market and products with a better service spirit. Improve their core competitiveness.