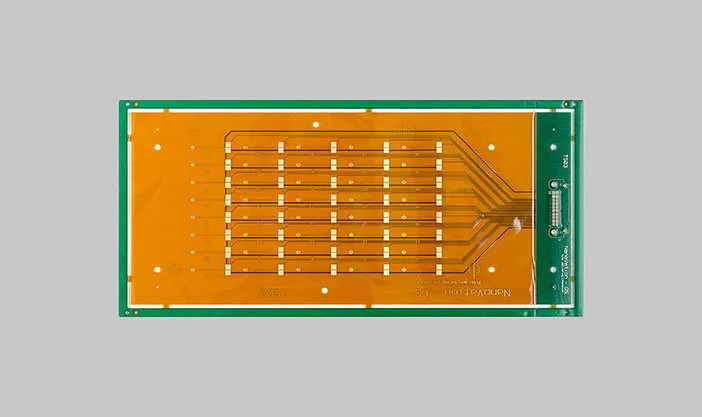

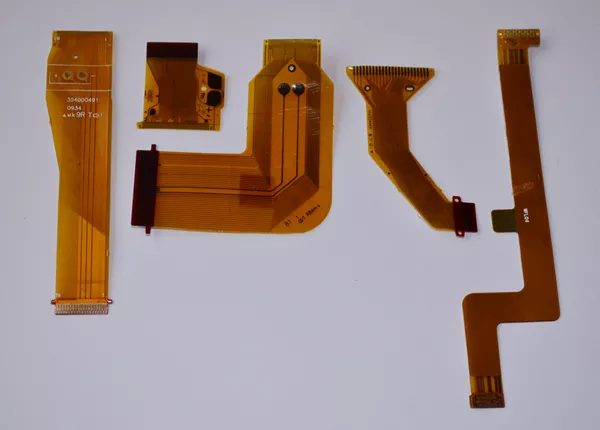

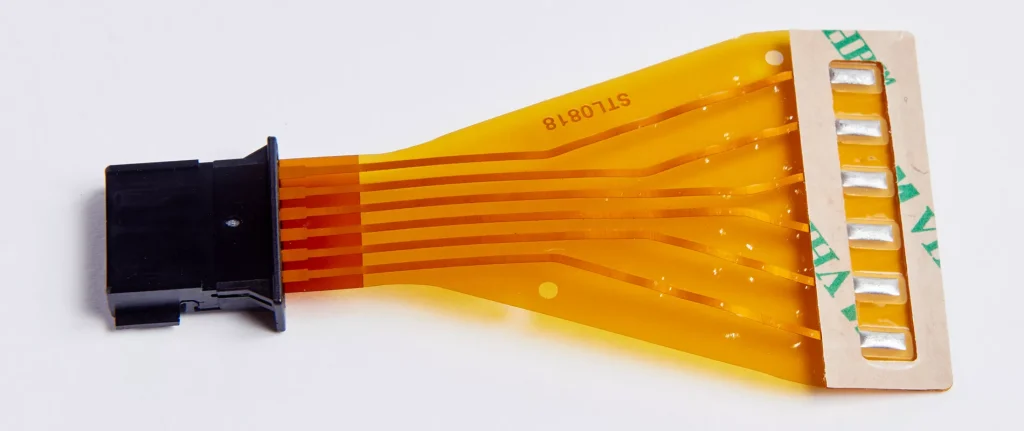

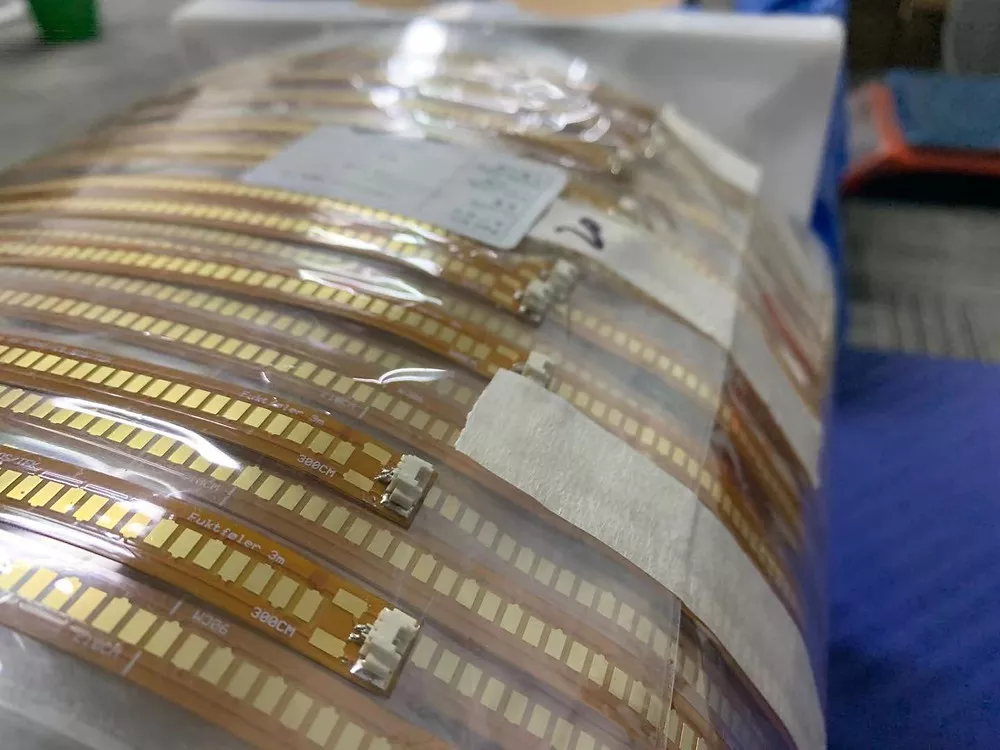

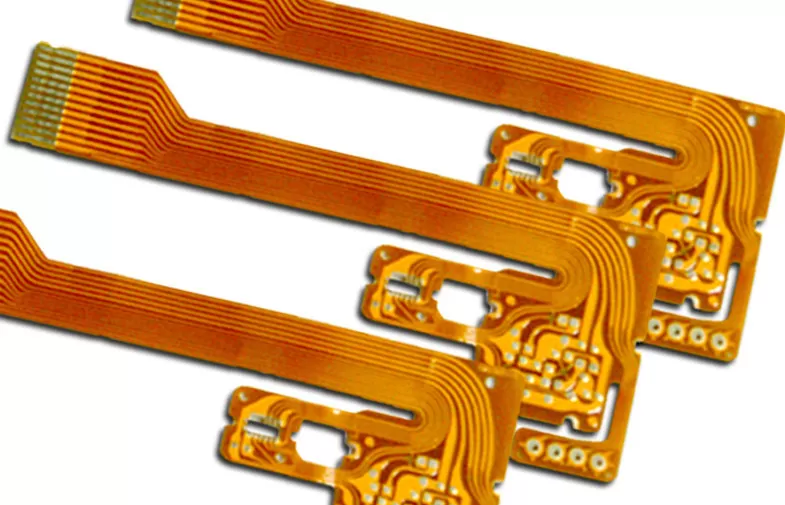

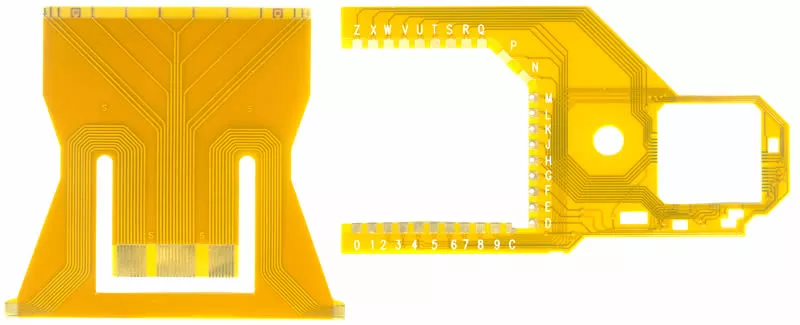

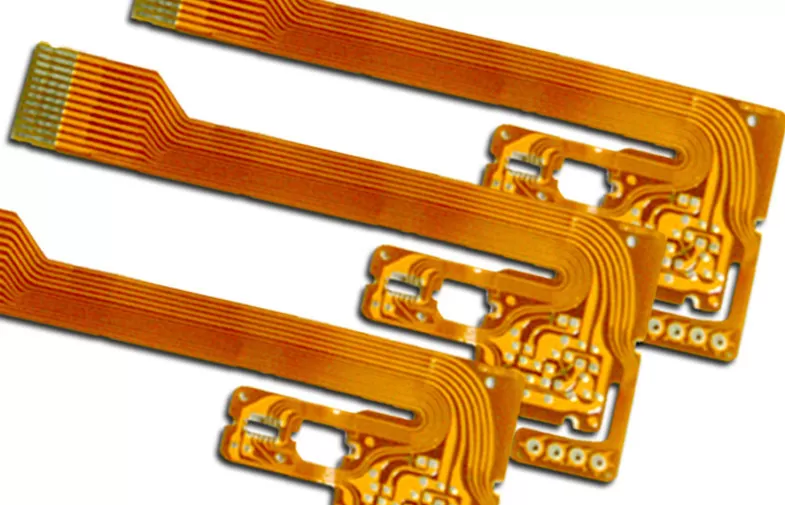

What is a polyimide printed circuit board? Polyimide printed circuit board, or FPC, is a highly reliable and excellent flexible printed circuit board made of polyimide or polyester film as the substrate. It is used in many cell phones, notebooks, and other electronic products and is the cornerstone of integrated circuit semiconductors.Polyimide printed circuit board is an important type of PCB, with the advantages of high wiring density, lightweight, thin thickness, foldable and bendable, Etc. Automotive polyimide printed circuit board has high barriers in customer certification, product process, technology, Etc., and has a broad application prospect in lighting, power battery, intelligent cockpit, and other modules. What are the characteristics of polyimide printed circuit boards? The traditional internal connection method is much cheaper if the circuit design is relatively simple, the total volume is not large, and the space is suitable. If the circuit is complex, handles many signals, or has special electrical or mechanical performance requirements, polyimide printed circuit boards are a better design choice. The polyimide printed circuit board assembly method is the most economical when the application’s size and performance exceed a rigid circuit’s capabilities. Flexible circuits with 12 mil pads with 5 mils through holes inside and 3 mil lines and spacing can be made on a single film. Therefore, direct chip placement on film is more reliable. Because no flame retardant may be a source of ionic drill contamination, these films may be protective and