- How do I choose a reliable manufacturer?

- What are the key points to note when choosing a flexible PCB manufacturer?

- Pay attention to the range of process capabilities.

- Pay attention to whether the production equipment meets the demand.

- Note whether the terms of the spelling board fork.

- Pay attention to whether the company’s products have quality assurance (such as whether to provide testing before leaving the factory)

- Pay attention to the process technology.

- Pay attention to see the manufacturer’s raw material supply system.

- What are the outstanding features of an excellent flexible circuit board fabrication manufacturer?

- What are some of the world’s leading flexible PCB manufacturers

- Are you looking for a flexible PCB manufacturer?

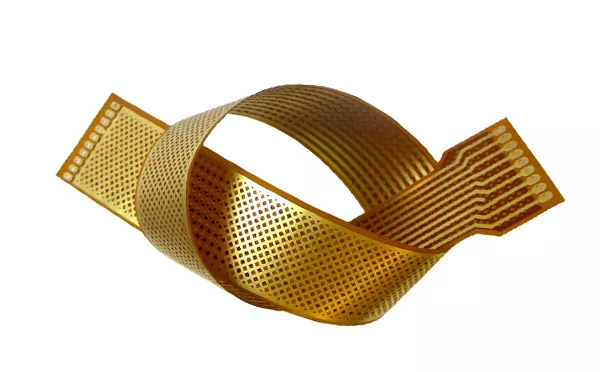

With the rapid development of electronic products, the demand for flexible PCBs is also becoming more and more prosperous. Flexible PCB currently on the market according to the combination of substrate and copper platinum division, the flexible circuit board can be divided into two kinds: with glued flexible board and non-glued flexible board; according to the number of layers of conductive copper foil division, divided into the single-layer board, double-layer board, multi-layer board, double-sided board, etc., can be freely bent, folded, wound, can be moved in three-dimensional space at will and expansion; heat dissipation performance is good, can use FPC to reduce the volume; can achieve lightweight The FPC can be lighter, smaller, thinner, thus achieving the integration of component devices and wire connections.

Flexible PCBs are also known as flexible circuits, printed circuit boards, flexible printing, and flexible circuits. They consist of a thin insulating polymer film with a conductive circuit pattern fixed on it and are usually provided with a thin polymer coating to protect the conductor circuit. Rigid PCB also known as a rigid circuit board, PCB ( Printed Circuit Board), the Chinese name for printed circuit board, also known as a printed circuit board, is an important electronic component, the support body of electronic components, is the carrier of the electrical connection of electronic components. Because it is made by electronic printing, it is called a “printed” circuit board.

If you are currently looking for a flexible circuit manufacturer to build your circuit board but don’t have much experience in this field, please take the time to read the following information. The choice you are about to make is too important. One of the biggest mistakes people often make is choosing the lowest bidder, and while it’s easy on the wallet, you could be setting yourself up for a lot of worry and frustration.

How do I choose a reliable manufacturer?

Flexible circuit board fabrication is one of the core tasks that many large-scale electronics production industries need to perform. FPC fabrication with quality and quantity is the most anticipated situation for major demand manufacturers. Therefore the selection of a quality and reliable flexible circuit board manufacturer has become incredibly important, so what kind of characteristics of the flexible PCB manufacturer are quality and reliable?

Do they have flexible PCB manufacturing equipment?

Reliable, flexible PCB manufacturers invest in the latest technology and modern equipment to provide their customers with high-quality flexible PCBs.

When you are in the market for the best flexible printed circuit board manufacturer, make sure you work with a company that selects and invests in the right equipment to provide you with high-quality flexible PCBs. Reliable PCB manufacturers look to increase efficiency and maintain quality by investing in their manufacturing facilities.

Does your potential flexible PCB manufacturer have board testers, drilling tools, imaging equipment, surface finishing tools, etc.? The right flexible circuit manufacturer has invested and taken the time to invest in the best and latest in the right PCB service providers. Thankfully, there is a variety of PCB manufacturing equipment available.

Do they have a flexible PCB technician?

In case you didn’t know, producing flexible printed circuit boards requires advanced manufacturing processes. Before the final product is completed, many steps are involved, and not all PCB companies are qualified enough to manufacture high-quality flexible PCBs.

The production of flexible PCBs requires skilled technicians to deliver high-quality flexible PCBs that work as required. Does your potential manufacturer have a team of technicians to manufacture high-quality PCBs for you? If not, you would be wise to find a company with flex PCB technicians, as these boards are critical to the functionality of your equipment.

What certifications and standards are available?

The right flex PCB manufacturer follows strict UL, ISO, and IPC rules, among others. When you are in the market for the right flexible PCB manufacturer, you must ensure they are certified and follow established rules and regulations.

For example, you should look for certifications such as UL 94V-0 fire protection.UL 94V-0 fire protection certification is something you should not forget when buying flexible PCBs. To be safe, avoid dealing with a flexible PCB manufacturing company that does not provide you with a certificate of compliance.

What are the key points to note when choosing a flexible PCB manufacturer?

When choosing a flexible PCB manufacturing company, choose a professional manufacturer through a comprehensive comparison in order to avoid a lot of unnecessary trouble; professional manufacturers produce the production of circuit board quality assurance, and after-sales service is also more secure; choose flexible PCB mass production service capability of the company is less risky. In choosing a flexible PCB, manufacturers should consider the following points.

Pay attention to the range of process capabilities.

When selecting a printed circuit board manufacturing company, try to choose a wider range of processes. Process capabilities to prevent the process involved more than the manufacturing company’s ability to affect the delivery date, so in selecting the relevant manufacturing company, first, detailed reference process requirements to prevent the lack of process leads to the electrical function being affected.

Pay attention to whether the production equipment meets the demand.

Due to the different types of printed circuit boards, there will be a huge difference between the manufacturing requirements and standards, and the type and grade of equipment used are also different. So in the selection of flexible PCB manufacturers need to contact the first production of PCB samples, try to choose a good reputation in the industry of printed circuit board manufacturers, and check whether the manufacturer has a high level of equipment, high technology content, high degree of automation production equipment.

Note whether the terms of the spelling board fork.

Because of the special nature of the production of circuit boards, the need to assemble the board shipped with a single risk of scrap, the general production company’s default customer acceptance of the terms and conditions of the forked board, if not accepted when the need to communicate with the processing side, usually the production side will add a certain fee. So it would help if you chose whether to accept the flat fork according to your situation.

Pay attention to whether the company’s products have quality assurance (such as whether to provide testing before leaving the factory)

When choosing a printed circuit board manufacturing company, you need to judge whether it has a quality control system, such as whether the product is tested before shipment, to avoid quality problems affecting the later use of the circuit board and to prevent the triggering of safety problems.

These are the considerations for choosing a flexible PCB manufacturing company. In addition, also need to pay attention to the relevant manufacturing company whether to provide invoice receipts, to see whether its invoices plus taxes and fees are in line with market norms; also pay attention to the distribution of circuit boards, as such precision products need to be properly packaged and safely distributed, to see whether the company can distribute, if not the ability to distribute when there is a distribution guarantee system.

Pay attention to the process technology.

Procurement can be from the board layers and special processes capabilities, such as copper thickness, line width aperture, impedance level, size, and other aspects of a board factory reference process; the more complex process capabilities of the board factory are more reliable. Look at the manufacturer can produce printed circuit board layers, board thickness, copper cladding thickness, and the minimum line width, line spacing, and minimum hole diameter can be achieved what hole diameter.

Pay attention to see the manufacturer’s raw material supply system.

Look at the board manufacturer’s raw materials, such as plates, ink, copper balls, Etc… Among them, the board is the most important; the difference between the board determines the board’s performance advantages and disadvantages. Board material is the main raw material of PCB, accounting for about 60% of the cost of PCB. By understanding the flexible printed circuit board manufacturer’s raw material supply system, it is easier to control the final quality of the PCB and also from the side to understand the manufacturer’s overall manufacturing capabilities.

What are the outstanding features of an excellent flexible circuit board fabrication manufacturer?

Has a superb PCB design and development team

Excellent printed circuit board manufacturers can produce superior quality circuit boards because manufacturers have a professional PCB design and development team that can provide plasticity advice for the design phase of the prototype product. Excellent PCB manufacturer core technical staff have many years of experience in designing and developing printed circuit boards, so they can strictly follow industry standards and process quality requirements to produce quality assurance PCB circuit board products.

Have a quality manufacturing line factory

Usually, quality manufacturers can strictly follow the management control system to produce; then, a quality flexible PCB manufacturer must have a quality manufacturing plant. Only with its production line factory be able to carry out strict production line control, effective supervision of production progress, and improve the probability of accurate handover, to ensure that customers’ order is placed after the fast and efficient completion of production tasks, to bring customers high-quality, durable PCB circuit boards.

Have a sound service system

A sound service system is one of the important elements to determine whether the manufacturer is excellent. Usually, excellent manufacturers have a perfect marketing service team, able to provide quality pre-sales and after-sales service; relevant professional service personnel can quickly provide a list of quotations according to customer needs to ensure that customers can be the first to get information about the product.

What are some of the world’s leading flexible PCB manufacturers

Which companies are currently more successful in the flexible PCB industry? Here is an introduction for you.

1, Nippon Mektron Technology Co., Ltd (Nippon Mektron) is currently a very important manufacturer in the flexible circuit board industry market, but also the largest. Together with branches and factories worldwide, collectively known as the NOK Group, Japan Flagship is also a major member of the NOK.

2, Taiwan Zhen Ding Technology Holdings Limited is the largest FPC manufacturer in Taiwan, is a listed company, and was established in 2006. Five manufacturing plants were built in Taiwan Taoyuan, Shenzhen, Qinhuangdao, Huai’an, and Yingkou. The main products include:

- Flexible printed circuit boards (FPC).

- High-density connection boards (HDI).

- Rigid printed circuit boards (RPCB).

- Integrated circuits (IC carrier boards).

3, South Korea InterFlex is the largest FPC manufacturer in South Korea, South Korea Young Poong group of companies, mainly supplied to Samsung, LG, and other Korean electronics manufacturers.

4, Sumitomo Denko (Sumitomo Denko) was established in 1897, one of the world’s top 500, with factories in Japan, the Philippines, Shenzhen, Suzhou, Vietnam, and other places. It is involved in five business fields: automotive, information and communication, electronics, electric wire, mechanical materials and energy, and industrial materials.

5、Nitto Denko is one of the top 500 companies in the world, with 100 companies worldwide. Its factory in China is Nitto Denko (Suzhou) Co.

6、Fujikura (Japan) was established in 1885, with a history of more than 100 years, most of Fujikura’s FPC production capacity is in Thailand, and the FPC factory in Shanghai has 1,500 employees. Its China factory is Fujikura Electronics (Shanghai) Co.

Are you looking for a flexible PCB manufacturer?

Before a company can go into full production, manufacturers must ensure that their printed circuit boards operate as expected. Since PCBs are an integral part of many electrical devices, they can be very expensive if they do not perform well after full production.

Anpollo can provide customers with a model to test before launching the final product. With a model, we can get feedback from the customer on what is correct and what needs to be changed or adjusted. This benefits the customer because the earlier issues and problems are identified in the model, the lower the cost.

Apple’s service capabilities include controlling product quality, providing reasonable prices, using environmentally friendly materials, and delivering products quickly. Still, more importantly, we can reduce manufacturing costs and improve manufacturing efficiency. On the one hand, we focus on the customer’s pain points of tight time, high requirements, and poor quality in the R&D stage; on the other hand, we solve the problem of scattered customer demands, such as PCB manufacturers, processing, and placement, BOM matching, etc., all need to find different companies, which seriously restricts the efficiency of product launch. Our established service system is good at catching the market demand, can do one-stop to meet customer needs, and has independent mastery of materials, processes, and equipment core advantages, with efficient research and development of industrialization and rapid mass production capabilities.

Are you looking for a flexible PCB manufacturer? We are helping customers from different backgrounds and enabling them to have final products using our quality facilities. We have enough design development and manufacturing experience to contact our customer support to get a good quote at your earliest convenience.