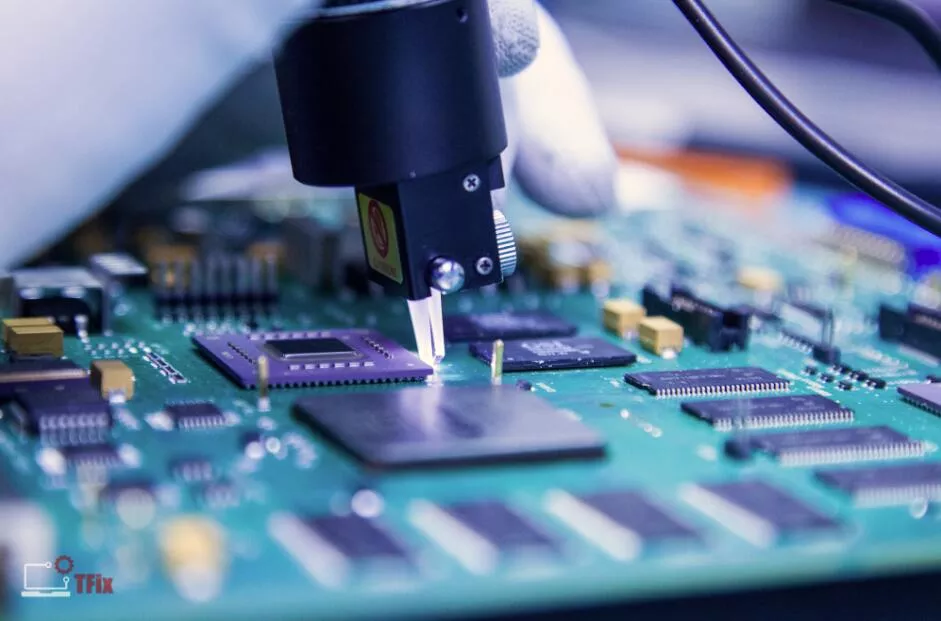

Thanks to today’s technological development, many cutting-edge electronic and signaling technologies exist. PCBs are particularly important in all electronic products for military and everyday applications. Therefore, choosing the right printed circuit boards for electronic products is very important.

The correct choice of material is of utmost importance to design and produce a PCB that meets the performance requirements. Generally, a wide range of substrate materials are available for PCB applications, ranging from FR-4 to Teflon.

High-quality materials enable the circuit board to work properly and meet the performance requirements designed for specific environments. This article briefly describes what materials are typically used in printed circuit boards.

In the design of printed circuit boards, the material is usually etched with winding and overlapping circuits according to different needs. Some boards require materials with electrical properties to achieve high frequencies and data speeds. And military or other specialized industries have PCs that must withstand very high temperatures and may require thermally conductive materials or boards that require heat dissipation solutions. Different boards for different applications require different materials.

The materials used in PCBs are usually composed of three elements: copper, resin, and glass, which work together to meet the specific needs of the electronic system. While the PCB’s substrate is usually made using a non-conductive dielectric material, the circuit board base sometimes called the chassis, consists of a substrate (or core) and a laminate. The laminate provides a copper foil or other surface material when used with the substrate. Circuit layers are primarily made of copper as the primary material. PCB design typically uses the following materials depending on the design and application.

Materials used for circuit layer applications

- copper

PCB materials are categorized according to the reinforcement material (most common)

- Cardboard – FR-1, FR-2 (phenolic cotton paper), FR-3 (cotton paper and epoxy resin)

- Epoxy Glass Cloth – FR-4 (glass cloth and epoxy resin), FR-5 (glass cloth and epoxy resin)

- Laminates – CEM-1 (cotton paper and epoxy), CEM-3 (nonwoven glass and epoxy)

- HDI Boards (RCC – Resin Coated Copper)

- Specialty Boards (metal, ceramic, etc.)

PCB materials are categorized by resin type

- Epoxy Resin

- Polyester resins

- PI resin (polyimide)

Flame-retardant properties categorize PCB substrates.

- Flame retardant (UL94-VO, UL94-V1)

- Non-flame retardant (UL94-HB grade)

Different materials are used in the manufacture of different types of PCBs. The following table summarizes the materials used to manufacture five types of PCBs.

| PCB Type | Material Used | |

| 1. | Paper Board | Cotton Paper and Epoxy |

| 2. | Epoxy Glass Cloth | Woven Glass and Epoxy |

| 3. | Composite Board | Cotton Paper, Non-Woven Glass and Epoxy |

| 4. | HDI Board | Resin Coated Copper |

| 5. | Special Board | Metal, Ceramic |

Consult the experts when designing and manufacturing PCBs

Choosing the wrong material when designing and manufacturing PCBs can delay a project or cause failure. That is why consulting experienced experts from the beginning is important. At Anpllopcb, our highly skilled engineers work with our customers from the beginning of any project, providing advice on materials, stacking, and design for manufacturability. Our expertise in advanced material types and combinations enables us to provide our customers with cost-effective solutions to any design challenge. We have the industry-leading processes, facilities, and teams to meet your custom PCB manufacturing needs. We invite you to contact us today so we can answer any questions you may have and learn more about your next PCB project!

thanks, interesting read

Thanks, I’ve been looking for this for a long time