In this article, we try to describe a topic clearly: what is PCB fabrication? As we all know, printed circuit boards (PCBs) are used in all electronic products. PCBs have made it possible for humanity to have electronic products that make life easier, such as computers, cell phones, computers, digital clocks, calculators, etc. Therefore, printed circuit boards (PCBs) support the entire electronics industry.

PCBs route electrical signals through electronic devices to fulfill the devices’ electrical and mechanical circuitry needs. It is the main solution to where the power and signals go to make the electronic products work. Manufacturing printed circuit boards is a complex process that begins with a product concept and ends with a fully functional PCB assembly. Next, we will talk specifically about PCB manufacturing.

Printed circuit board manufacturing can be defined as combining the layers of a circuit board with a specific surface pattern before making it fully ready for electronic manufacturing. The printed circuit board manufacturing process begins with a design or diagram that defines the specifications and requirements of the PCB.PCB layout is an important part of the manufacturing process. It involves schematic design and is created by PCB design engineers after considering the following factors: what the PCB needs to do, its functional attributes, and under what conditions it will be used.

In this process, the PCB manufacturer’s design engineers will create schematics to capture network connections, lay out the physical circuits in the PCB design, and order the electronic components. After soldering the components to the board and completing assembly testing and validation, the board is integrated into the overall system.

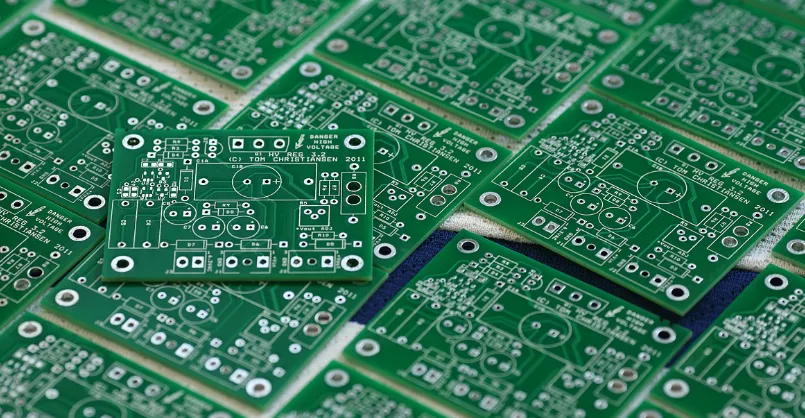

The entire process of creating a circuit board from start to finish can have many intricate details that must be completed to be successful. One area of the process that does not get the recognition it deserves is the fabrication of bare boards.PCB fabrication creates bare boards for the printed circuit board assembly. You should choose your PCB fabrication contractor carefully, as even a small mistake can damage the entire board, rendering the final product useless.

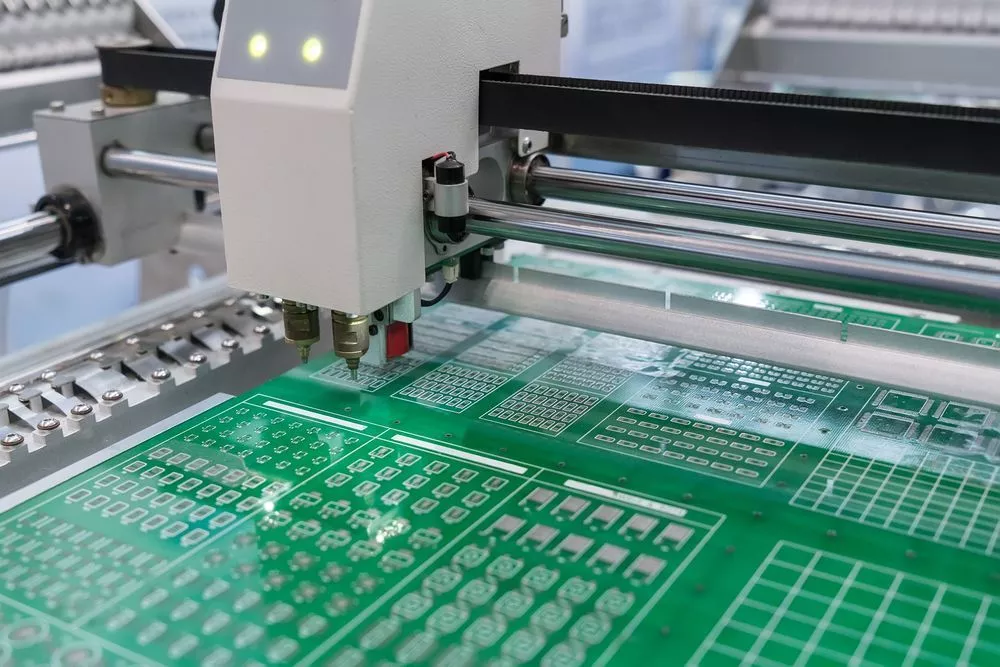

The printed circuit board (PCB) manufacturing process requires complex processes to ensure the finished product’s performance. Although circuit boards can be single, double, or multilayer, the manufacturing process varies only after producing the first layer. Due to differences in PCB construction, some PCBs may require 20 or more steps in the manufacturing process.

The number of steps required to produce a printed circuit board is related to its complexity. Skipping any steps or reducing the program may hurt the board’s performance. The PCB can only perform its task correctly as a critical electronic component after successful completion.

The PCB manufacturing process involves a great deal of work. To ensure that the PCB is manufactured with the quality, performance, and durability you expect, before proceeding with PCB design, it is recommended that product circuit designers visit a PCB board shop and communicate face-to-face with the manufacturer about PCB manufacturing requirements. It helps prevent designers from making any unnecessary mistakes during the design phase.

Need someone to fabricate your PCB? Anpllopcb can help! To get PCBs that meet the performance and quality of your project’s final design, you must choose a manufacturer that has a high level of expertise and focuses on quality at every stage.

Anpllopcb offers a wide range of services. The customer can provide the design, or Anpllopcb can design the board using the specifications provided by the customer. The design provides information about the operations that need to be performed on the board and the environment in which it will be used so that Anpllopcb can develop and test an appropriate schematic.

Customers can also develop their files and send them to the manufacturer using a format called Gerber files. This is the industry standard for documenting PCB specifications.

Anpllopcb uses Gerber files to set up and program our manufacturing equipment for PCB manufacturing. The actual process varies depending on the number of boards to be produced. Customized products need to be produced in small batches and are more expensive, while standard generic formats are cheaper. Prototypes are, by definition, very small and, therefore, very costly.

Anpllopcb accepts a wide range of work and can provide various boards to meet your needs. Other services include design and other product development activities to support you.

The success of our customers measures our success, so we focus on the details required for each PCB manufacturing step. We also offer vacuum packaging, weighing, and delivery services to ensure your PCB orders arrive safely and without damage. To date, we have supplied printed circuit boards to companies of all sizes from more than 80 countries, and our goal is to ship PCBs we manufacture to every corner of the world for years to come.

We offer fast PCB prototyping, volume PCB production, and assembly services. Quotations are always fast and free.