Your time is valuable, and not paying enough attention to your printed circuit board (PCB) manufacturing quality can cause many problems in your PCB development process. These problems will waste your time and may lead to the failure of your project. Printed circuit boards have a significant impact on modern life. Failure to meet PCB design and manufacturing requirements can lead to failure of products and projects if the board cannot be manufactured, has a low yield, or fails prematurely.

Therefore, it becomes important to know about it, so if you want to know what PCB design is, continue reading this article.

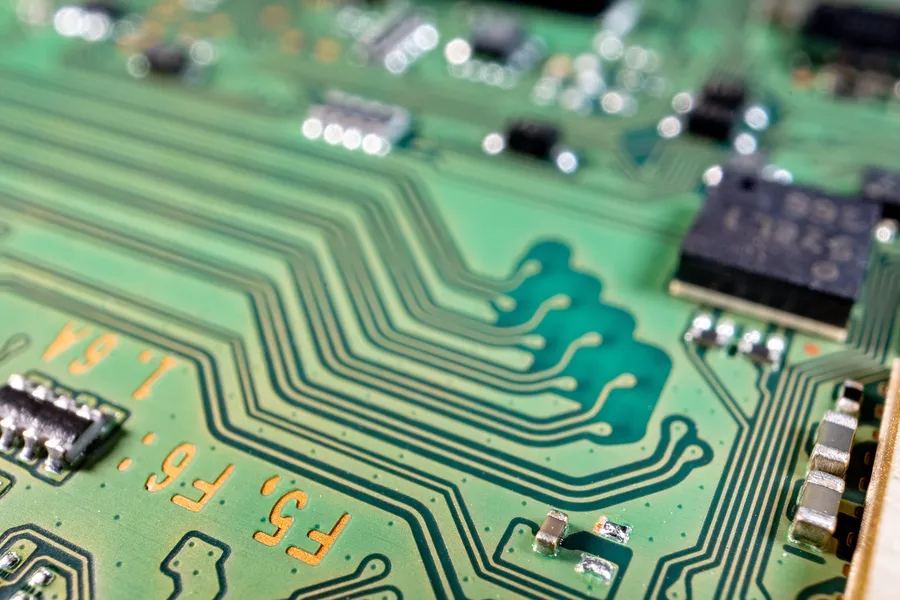

What is PCB design?

There may be a question in your head, “What is PCB design?” wondering why PCB design is so encompassing. It is more than just a simple definition; it has become a multidisciplinary process requiring collaboration, integration, and digital transformation, among other comprehensive disciplines and industries. It is more than just a simple definition.

PCB design creates a printed circuit board (PCB) through collaboration and integration between multiple disciplines and domains, including electrical, mechanical, software, systems, test, and manufacturing. It is a process that can give life to the physical form of an electronic circuit board. The goal is to create functional, reliable, cost-effective printed circuit boards that meet the electrical and physical requirements of the end product.

However, the success of PCB design is not just about success on the drawing board; it is also about providing supply resilience to the electronic system design through design-time verification of part availability, BOM validation, substitution validation, etc. The key to achieving resilience in PCB design is to have a critical mass of expertise, intelligence, and readiness for optimization.

PCB design is a project that requires continuous two-way communication between teams. In today’s era of increasingly complex electronic designs, the design team must be able to deliver complex PCB products in a short period, which is to ensure that the final product wins the market conditions.

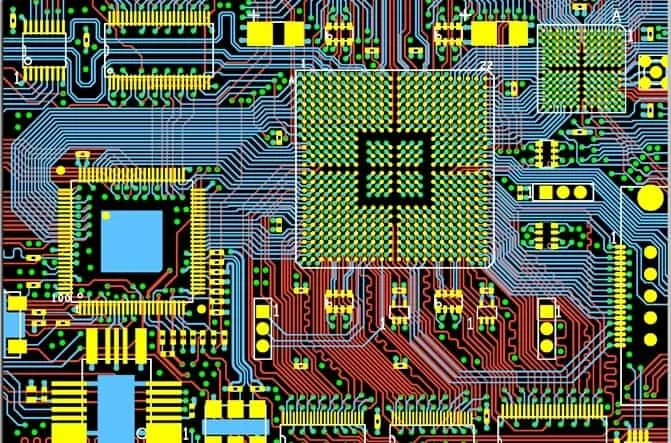

PCB design is like the planning and design of a city

PCB design is like “designing a city.” The planning and design of a city include land, structural foundations, buildings, houses, and roads. All these are interconnected to form the city we live in. Therefore, at the beginning of any PCB design need to communicate with the PCB design engineers and discuss all the needs of the project with the PCB manufacturer for open, continuous communication and ensure that the same opinion only then can be based on the project needs to design a qualified product, otherwise the “city” will become chaotic, there is Otherwise the “city” will become chaotic and incompatible everywhere. While no design can be 100% perfect, waiting for the right design after full communication will reduce the probability of having to make extensive changes, and even if there are minor modifications, they will not jeopardize your project and timeline.

Therefore, when you start the design or submit the design, it is important to determine the correct board size, alignment width, material, component layout and tolerances, and other parameters; if you are carrying out a flexible design, you also need to determine if the design is static. Dynamic? Or is it a combination of hard and soft?

In addition, it is important to determine the environment in which the final product will operate. Will the PCBs applied to the final product be used in non-extreme environments (e.g., cell phones) or extreme environments (e.g., deserts, explosions, etc.)?

You may have questions about the PCB design and layout process, and this is where you can find a reputable PCB manufacturer with extensive engineering experience whose experience can answer your questions.

Conclusion

PCB design is just the beginning for those who want a printed circuit board, and PCB design layout is critical for proper product functionality. If you want to know how to make the best layout design for PCB manufacturing, you can contact Anpllopcb to provide more information about the relevant solutions. Get in touch with our team of experts.