- Causes and prevention of false soldering of printed circuit boards.

- 1, PCB assembly when using the components factors caused by the false solder and its prevention.

- 2. the printed circuit board substrate factors caused by false welding and its prevention.

- 2.1. PCB oxidation caused by false soldering and prevention

- 2.2. PCB pollution caused by false soldering and prevention.

- 2.3. PCB deformation causes false solder and prevention.

- 2.4. Different processes and materials of PCB surface solderable layer

- 2.5. PCB in reflow soldering in high-temperature time warpage deformation

- 3, flux, solder factors caused by the false solder, and its prevention

- 4, other factors are causing false solder and its prevention.

- PCB manufacturing of Anpllopcb

According to statistics, electronic machine product failure nearly half is due to PCB manufacturing caused by poor welding, almost more than the probability of failure of electronic components, which reduces the reliability of electronic products, light noise increases technical indicators deterioration, the heavy PCB circuit board can not complete the design function, more serious is to cause the whole system in the absence of any precursors to the sudden collapse of the case This will cause significant economic losses and loss of reputation.

In the production of electronic products test links and after-sales maintenance links, PCB failure is caused by false soldering so that the technical staff, in time, the energy caused a great waste, sometimes finding a false soldering point, with a full day is not uncommon.

Even from all aspects of the effort, the printed circuit board production and maintenance process also can not eradicate the phenomenon of PCB solder. Therefore, the printed circuit board solder has been the focus of the electronics industry problems.

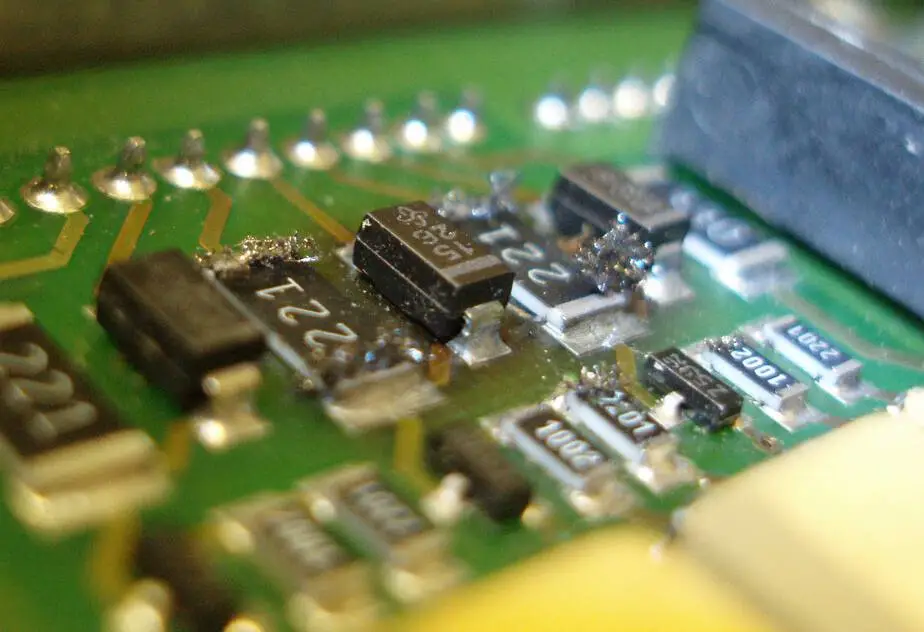

Void soldering: one of the bad solder joints produced in the manufacturing process of PCB circuit boards for electronic products; the solder joints are not formed on the interface of good intermetallic compound (IMC), which makes the formation of an unreliable connection between the components and the substrate. (Here, the definition of false solder refers to the PCBA solder joints’ false solder.)

Causes: PCB substrate solderable surface and electronic components solderable surface is oxidation or pollution; solder performance, flux performance, PCB substrate pad metal plating is poor; welding parameters (temperature, time) are not set properly.

Impact: PCB circuit board false solder so that the solder joints become or have a contact resistance of the connection state, resulting in the circuit does not work properly or there being an electrical connection when the unstable phenomenon, the noise in the circuit (especially in the communication circuit) increased and no regularity, to the circuit debugging, use and maintenance of major hidden dangers. In addition, some false solder joints in the circuit start working for a longer period to maintain good electrical contact, so it is not easy to find. However, in temperature changes, humidity changes and vibration, and other environmental conditions, the contact surface is gradually oxidized, the contact slowly becomes incomplete, and then the PCB board circuit “strikes.” In addition, the contact resistance of the virtual solder joints will cause local heating and temperature rise, promote incomplete contact with the solder joints to deteriorate the situation further, and eventually even make the PCB circuit board solder joints off if the circuit does not work properly. This process can sometimes take up to one or two years.

In PCB production and maintenance services, finding out from thousands of solder joints in the PCB caused by the failure of the false solder point to this is not an easy task. Therefore, the virtual solder is a major hidden danger to the reliability of the circuit, so we must pay attention to the study of its laws and measures to reduce its harm.

The characteristics of the false solder: from the perspective of PCB board testing, part of the false solder joints in the production of the test link shows the characteristics of the time pass when not, the fault, although more troublesome to find, can be solved before the faulty solder joints in the factory; another part of the false solder joints often in a year or even longer before the phenomenon of open circuit, so that the product stops working, causing losses.

The printed circuit board assembly process caused by false soldering has its hidden nature, and the accidental nature of the failure and the significant loss of system collapse can not be ignored.

Causes and prevention of false soldering of printed circuit boards.

1, PCB assembly when using the components factors caused by the false solder and its prevention.

In PCB assembly, when using components solderable part of the metal plating thickness is not enough; oxidation, pollution, and deformation can cause false soldering results.

1.1. Solderable part of the metal plating thickness is not enough

Usually, components can be soldered surface plated with a certain thickness, silver-white, uniform easy to solder tin layer; if the plating is too thin or uneven, as well as copper-based tin plating or steel-based copper plating and then tin plating, the copper and tin in contact with each other to form the copper-tin interface, the two metals in contact for a long time will penetrate each other to form an alloy layer diffusion, so that the tin layer becomes thin, resulting in a decrease in the solderability of the solder surface. (Solderability refers to the ability of the metal surface to be wetted by the molten solder) Long-term cooperation with large companies’ components can reduce the risk of false solder caused by this reason.

1.2. Oxidation of the solderable surface of components

Due to long storage time or improper storage conditions, electronic components can cause the electronic components’ pins or solder end surface oxidation, resulting in the generation of false solder. After the oxidation of the solder surface, a gray, black, and visual inspection can be more serious for the oxidation of electronic components or discarded, or to oxidation treatment qualified and then used. General processing oxidation layer using external force rub, scrape; micro acid cleaning; apply flux, then enamel. (surface mount components, because of its package volume is small, oxidation is generally not easy to deal with, usually returned to the manufacturer to exchange or scrap processing)

In the PCB assembly process, whether components oxidation in addition to visual inspection, there are more complex and detailed solderability test detection standards, the conditions do not have, available manually, wave soldering or reflow soldering method, the components for batch sampling test welding.

1.3. Components can be soldered surface contamination

In PCB production, the components should go through incoming material receiving inventory, storage, issuing material, molding, and plug-in (THT process), SMC and SMD loading and unloading, placement and manual fill welding and other processes or operations, will inevitably produce dust, oil and sweat pollution, causing the electronic components solderable surface of the solderability decline.

In the PCB assembly production site, maintaining a clean production environment, wearing protective equipment, and operating strictly according to the operating procedures are effective measures to prevent component contamination.

1.4. Component pin deformation

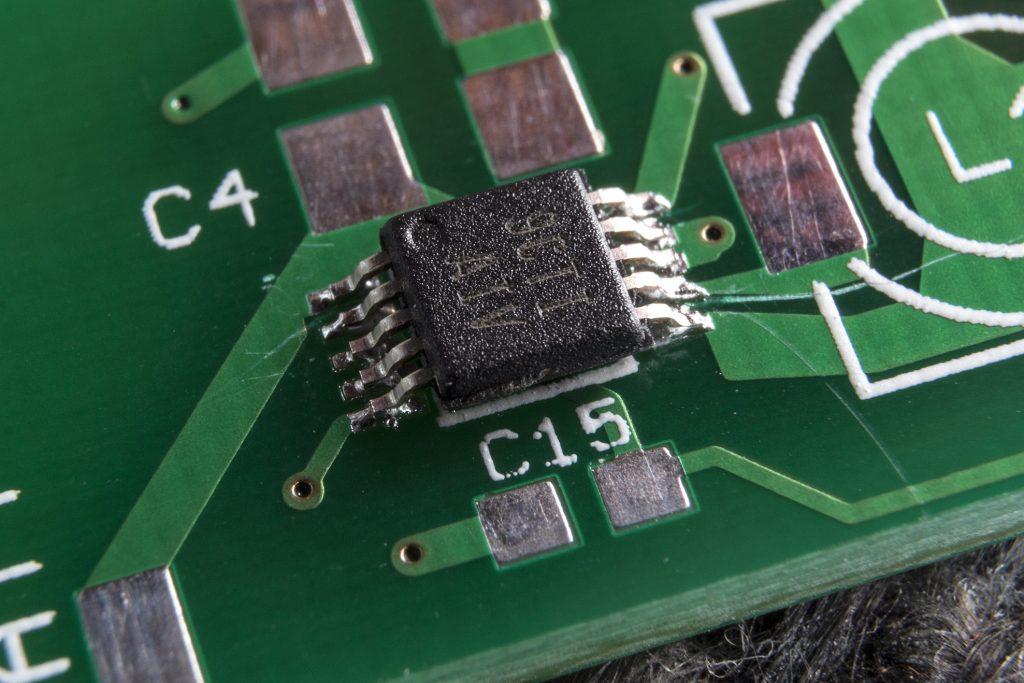

SMD devise, especially among the fine pitch QFP, SOP package device, the pin is very easy to damage deformation, pin coplanarity becomes poor, and after mounting, part of the pin is not close to the pad, resulting in false welding.

Prevention: for fine pitch mounting IC, use special tools to take and put; remember not to touch the pins directly by hand during operation, prevent IC from falling; QFP is commonly used for tray loading, SOP is generally rod-type packaging (avoid bending during production), after deformation of IC feet, should be shaped and checked before mounting. (e.g., QFP can be corrected and checked on a flat steel or glass)

2. the printed circuit board substrate factors caused by false welding and its prevention.

In the printed circuit board assembly process, PCB oxidation, pollution, deformation, Etc., can cause false soldering. (PCB insertion hole pad design is also one of the causes of false soldering, not discussed here).

2.1. PCB oxidation caused by false soldering and prevention

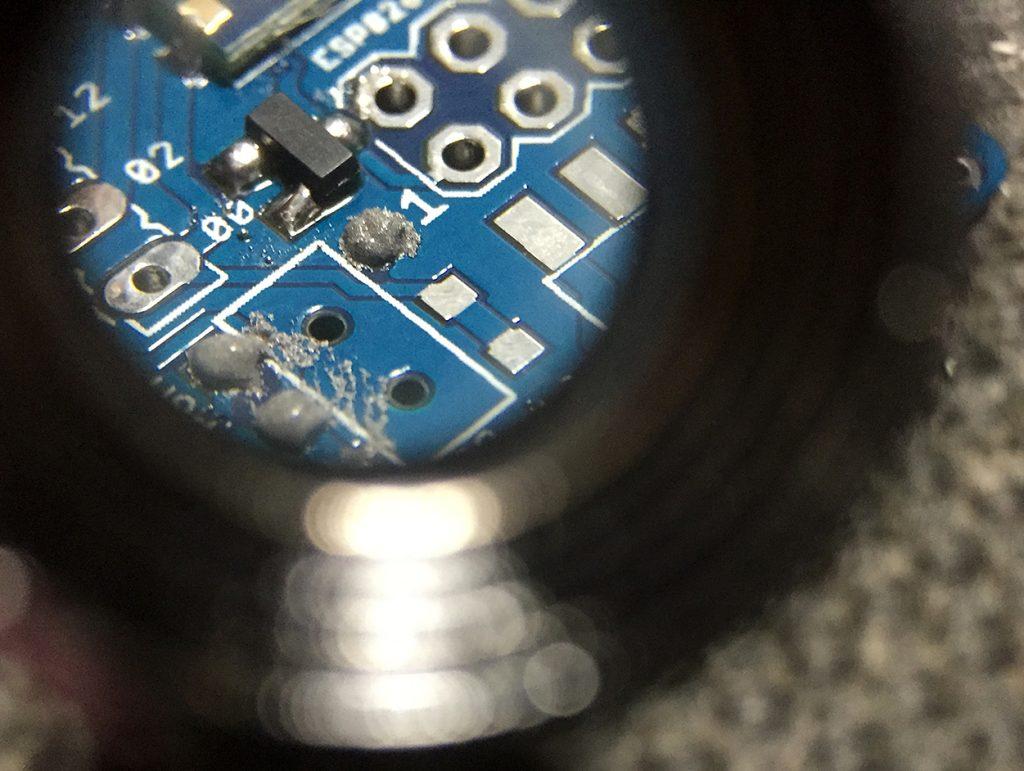

Due to long storage time or improper storage conditions, PCB can cause the pad plug-hole wall oxidation, resulting in the generation of false solder.

After oxidation of the pad, the loss of metallic luster, gray, and black, there is also no visual inspection of abnormalities. PCB suspected of oxidation, to be standard solderability test, the results are good before use. The following are PCB storage conditions for various surface treatments, storage periods, and baking conditions.

Silvered boards: storage conditions before and after vacuum packaging: temperature <30 ℃, relative humidity <60%. The effective storage time after vacuum packaging is six months to one year. Storage time of more than six months to avoid the plate storage moisture caused by the explosion of the board, usually unpacked with baking to remove moisture within the board, baking conditions for 120 ℃, 1 hour. (The longest time should not exceed 2 hours), use a clean and dedicated oven; the top and bottom sides of the silver board should be covered with aluminum foil to avoid oxidation of the silver surface or dielectric adsorption contamination.

osp board: the storage conditions before and after vacuum packaging: temperature 20 ~ 30 ℃, relative humidity <50%. The effective storage time after vacuum packaging is 3 months to one year. Storage time of more than six months. To avoid the board storage moisture caused by the board explosion, use the unpacked baking method to remove moisture within the board, baking conditions for 110 ~ 120 ℃, 1 hour. (The longest time should not exceed 1.5 hours).

The storage conditions before and after vacuum packing: temperature <30 ℃, relative humidity <60%. The effective storage time after vacuum packing is six months. Storage time of more than six months to avoid the board storage moisture caused by the explosion of the board, usually unpacked by baking to remove the moisture inside the board, baking conditions for 120 ℃, 1 hour. (The maximum time should not exceed 2 hours). The storage conditions before and after the vacuum packaging of the spray tin plate: temperature <25 ℃, relative humidity <60%. The effective storage time after vacuum packing is one year. When the storage time exceeds six months, to avoid the board explosion caused by moisture, usually unpacked by baking to remove the moisture inside the board, baking conditions for 120 ℃, 1 hour. (The maximum time should not exceed 1.5 hours).

2.2. PCB pollution caused by false soldering and prevention.

PCB board in the production process, PCB receiving, storage, SMT printing, placement, THT plug-in, wave soldering, and other processes, the operator has to contact with the PCB, dust, oil, and sweat will contaminate the pads, so that the PCB solderability decline, resulting in false solder.

Maintaining a clean production environment and operating according to the production process procedures is a good habit to avoid PCB contamination.

PCB found to be contaminated should be cleaned and dried before use.

2.3. PCB deformation causes false solder and prevention.

PCB deformation, component placement of coplanarity becomes poor, part of the component foot and pad overhang (distance is small, may otherwise cause empty welding), resulting in virtual welding. Especially SMT process BGA and QFP package components, the formation of virtual soldering is more likely.

In general, PCB deformation has two situations: one is the incoming material deformation, good incoming material, and the PCB according to the formal acceptance.

PCB board warpage standards, please refer to IPC-A-600G section 2.11 flatness standards: for surface-mounted components (such as SMT mount) of the printed circuit board warpage and bowing standards for not more than 0.75%, other types of boards for not more than 1.5%. Test method reference IPC-TM-650 2.4.22.

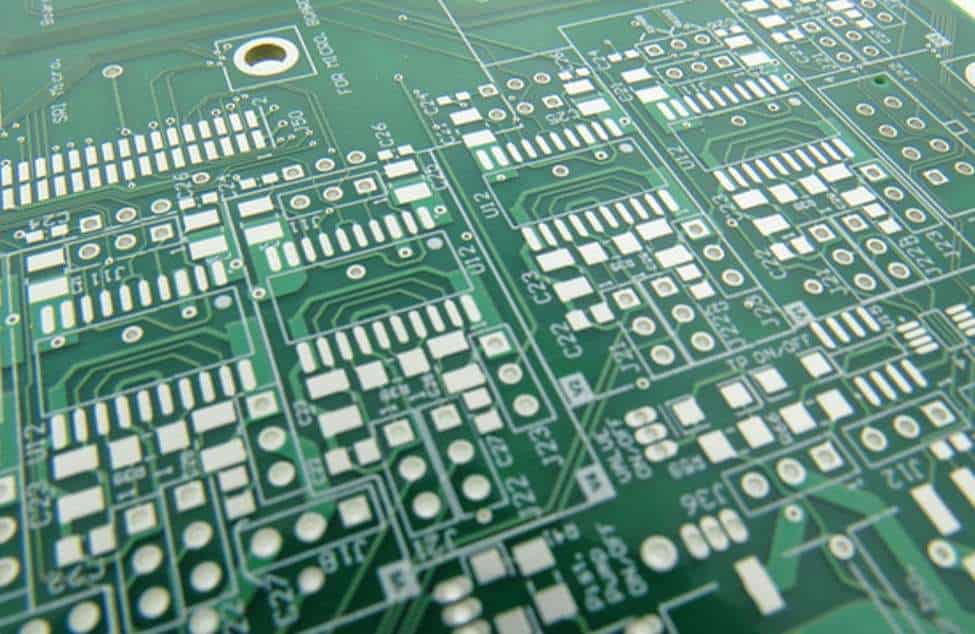

2.4. Different processes and materials of PCB surface solderable layer

PCB surface solderable layer with different processes and different metal materials, its solderability index is not the same; if the solderability index is not qualified, it is also a major cause of false solder.

2.5. PCB in reflow soldering in high-temperature time warpage deformation

Part of the PCB in the reflow soldering high-temperature warpage deformation after cooling back to the flat, resulting in false solder and causing greater stress, the possibility of late failure of the solder joint.

3, flux, solder factors caused by the false solder, and its prevention

3.1. Flux causes and prevention of false solder

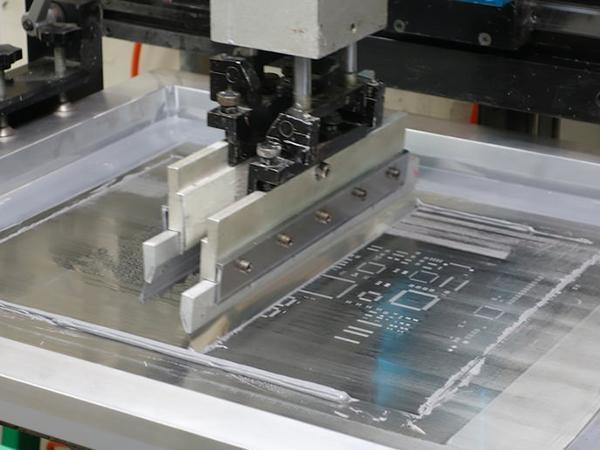

Pcb in THT or SMT, THT mixed assembly process, wave soldering before flux coating, flux performance will not effectively remove the component soldering surface, and PCB inserts hole, pad oxide, resulting in solder joint solder. This replacement of flux manufacturers or models should be paid special attention to. In particular, the use of new flux models should do the soldering test. Flux to often check the concentration, to be updated according to the process protocol.

3.2. Solder factors caused by false solder and its prevention

Pcb in the wave soldering process, tin-lead solder in 250 ℃ high-temperature oxidation, so that the tin content of the solder is declining, deviating from the eutectic point, resulting in poor solder fluidity, false solder, and insufficient strength of the solder joint. The following methods can be used to solve this.

Add redox agent so that the oxidation of SnO is reduced to Sn, reduce the generation of dross; constantly remove the solder slag; add a certain amount of tin before each solder; use the solder containing antioxidant phosphorus; use nitrogen protection welding so that nitrogen to isolate the solder from the air, to reduce the generation of slag greatly.

The better method is to use phosphorus-containing solder under nitrogen protection, which can control the rate of floating dross to the lowest degree with the least welding defects.

Pcb reflow process in the SMT process, solder paste in use will also continue to oxidation, the metal content of which is getting lower and lower, or the flux becomes less, will also cause false solder. A reasonable choice of reflow temperature curve can reduce the generation of false solder.

Between the improper match, the solder and PCB metal layer, solder, and component foot metal layer will also cause false solder.

Leaded solder mixed with lead-free solder end, if the use of leaded solder temperature curve, leaded solder first melts, while the lead-free solder end can not be completely melted, so that the interface of the component side can not generate a good intermetallic alloy layer, so the leaded solder mixed with lead-free solder end when the worst quality of welding. In this case, the welding temperature can be increased, generally, to 230 ~ 235 ℃ can be raised.

4, other factors are causing false solder and its prevention.

4.1. wave soldering and reflow solder cooling solidification process, PCBA jitter generated by the disturbance of the solder joints, its strength is low, in the use of customers in the solder joints are very easy to open circuit failure, electronic assembly, but also often classified this situation in the category of false solder.

4.2. When there is a large bend in the PCBA, the product assembly, fixed in the chassis base, the PCBA is forced to flatten, resulting in stress, and the solder joints, over time, will produce cracks, resulting in an open circuit. (Strictly speaking, this should be a late failure of the solder joints, a broad sense of false solder too). The prevention method is to use the flatness of qualified PCB, such as in wave soldering and reflow soldering out of the oven, due to the hot plate is not flat and caused by bending, can be a wave soldering or reflow soldering to restore its flatness; remember to bend to correct artificially.

4.3. Another situation is that the PCBA is flat. However, its fixed base is not flat (theoretically, N fixed base, generally only three in a plane), so the installation effect with the above 2). The same result is produced at a later stage.

The mounting base should be flat, and the number of PCBA fixed base is not the better can reach the fixed strength requirements. The more fixed base PCBA installation after the emergence of the micro-uneven situation can be more powerful.

4.4. In the use of the circuit board is often subject to external forces in part, such as the PCBA has a key switch near the solder joints that is very easy to use in the process of frequent micro-bending metal fatigue leads to the failure of the solder joints, (the result is the same as the solder joints false solder).

4.5. PCBA near the heating element solder joints are relatively easy to fail and open the circuit; the effect is the same as false solder.

4.6. PCB in the production process to remember to prevent bending; otherwise, the over-hole metalized wall cracks, resulting in the phenomenon of sometimes passing and sometimes not, very easy to misjudge with false solder.

PCB manufacturing of Anpllopcb

In today’s high-tech world, printed circuit boards are becoming more and more complex as technicians find ways to load more data and energy onto smaller and smaller chips. As computer equipment and electronic devices become smaller, the PCBs that power and connect them to the radio network will also become smaller. For PCB manufacturers, this means that the production of printed circuit boards will require advanced levels of engineering.

To increase the efficiency of PCB manufacturing to current standards, you must have properly specified bare PCBs to perform each step in the assembly process more efficiently. At Anpllopcb, we use the latest technology in our facilities to complete each bare PCB order to customer specifications. For more information on PCB manufacturing, please contact Anpllopcb.

Do you have questions about our services or your project? Contact us today to speak with Anpllopcb’s award-winning support team!