OUR SERVICES

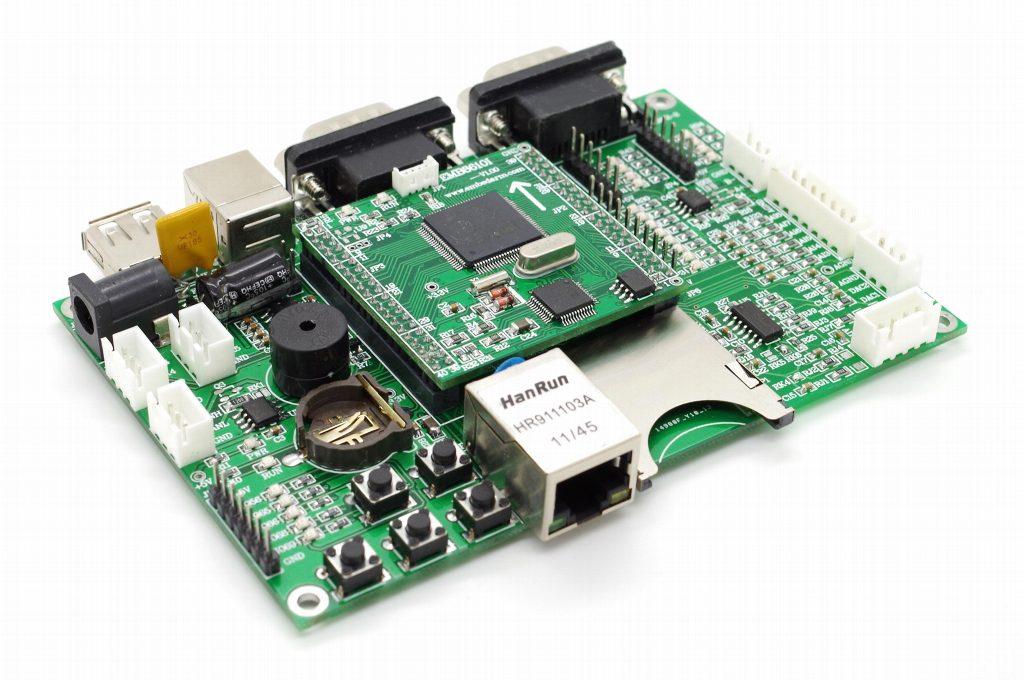

One-Stop Full Turnkey PCB Assembly Service

As a professional contract turnkey PCB assembly manufacturer with extensive experience in PCB fabrication, parts sourcing, design, and assembly for electronics, we are outsourcing companies or individuals. Our specialty ranges from prototype to high-volume assembly based on full and partial turnkey PCB assembly. We have been globally serving customers with high-quality PCB board assemblies and reliable, industry-leading contract manufacturing services.

Turnkey PCB Assembly

The term “Turnkey” refers to a product manufactured or service offered so that such product or service can be traded or sold to any customer as a finished product or service. Turnkey products or services are ready for instant use by customers. This is different from Build to Order-a type of approach in production-where products are built in line with the customer’s specifications and requirements, or when an incomplete product is sold to the buyer on the assumption that the buyer will complete the product’s production.

In PCB assembly services, turnkey assembly refers to services where every aspect of a PCB production is managed on your behalf by a PCB assembly manufacturer or supplier. Turnkey solutions PCB assembly factory and supplier procure the parts, and components, assemble the PCBs and manage the storage and delivery of the PCBs. Turnkey PCB assembly service requires much knowledge and expertise in PCB design and manufacturing, such as PCB design and fabrication, components, assembly processes, and the finished product.

Turnkey PCB assembly services typically use cloud-based software and advanced machinery to effectively and efficiently assemble circuit boards in high volumes than small or medium businesses could handle. Turnkey PCB assembly exists in two forms: full and incomplete turnkey PCB assembly services.

What Are Full Turnkey PCB Assembly Services?

Complete Turnkey PCB assembly services require the turnkey PCB assembly manufacturer and supplier to be responsible for every process involved in assembling your product circuit boards. Although most electronic or electrical OEMs will develop their design, numerous electronic OEMs won’t understand the details of a complete turnkey PCB assembly service. These include schematic development, selection of components, DFM (Design For Manufacturability), and DFT (Design For Testability).

Schematic Development involves:

- Circuit recommendations and guidance for optimum functionality

- Documentation creation and clean-up

- Preparation for the PCB layout

Selection of components is carried out for:

- Optimum functionality of the circuitry

- Verification of the PCB footprints and schematic symbols

- Best configuration for cost and availability

Design for Manufacturability provides:

- The right clearances between the components and various features on the circuit board

- The best placement of the components for soldering

- Access to the connectors and various interfaces

Design for Testability ensures:

- Each component is verified to be accessible and available for automated testing

- Probe points are provided for the debugging of critical circuitry

- The creation or modification of test programs and fixtures.

In order words, the turnkey PCB manufacturer or supplier collects the components and manufactures the circuit boards based on your specification or order and in line with best practices and industry standards. You are only required to provide the following:

- The product’s dimensions and sizes

- A BOM (Bill Of Materials) for the PCB design

- Gerber files containing needed information on every layer of the physical board of your PCB design are represented by a draw or flash code (ASCII Code) and defined via several vector coordinates.

- Packaging as well as shipping information.

If you don’t have the above-required resources, contact the turnkey PCB assembly manufacturer or supplier for assistance.

A complete turnkey PCB assembly service is more typically an investment than a partial one. It is used for building all shapes, sizes, and technologies of circuit boards. Achieving these requires an advanced manufacturing operation and extremely proficient service at high-mix, low-volume PCB assembly. Complete turnkey PCB assembly is about quality, from inspection to the final Quality Assurance (QA) and shipment. However, it can improve your experience of PCB acquisitions-especially if you are a newbie in dealing with printed circuit boards. Turnkey PCB assembly services offer all PCB manufacturing services, including PCB prototyping, management, aftermarket, delivery, administration, data collection, circuit designing, and sourcing of parts and materials.

Turnkey PCB Manufacturing

As one of few quality-focused PCB manufacturers that include electronic assembly services, Our single-source approach saves you time and money while ensuring more reliable, consistent results than when dealing with several suppliers. Our professional team can skillfully manage your entire project from concept to delivery and make the electronic assembly process as smooth and seamless as possible.

What Is A Partial Turnkey PCB Assembly Service?

Partial turnkey PCB assembly service is a type of consignment manufacturing where only a part of the PCB assembly process and service is outsourced. It can be described as “partial” outsourcing. A partial turnkey PCB assembly service is a model where the turnkey PCB assembly manufacturer and supplier maintains or controls certain parts of the entire manufacturing supply and production chain, in-house-especially purchasing or/and or PCB assembly. This type of turnkey PCB assembly sees the manufacturer and supplier responsible for sourcing, sorting, and packaging the materials to be delivered to the PCB assembler.

Partial turnkey PCB assembly is favored by many OEMs owing to the following reasons:

- This type of assembly helps strike a good balance between kitted and turnkey.

- A customer provides expensive parts such as connectors, ICs, etc., whereas the PCB assembler will source the rest of the parts, which helps save time for both sides.

- If customers have built strong supply chain relationships, they can easily benefit in terms of prices by sourcing parts at cheaper rates.

- The Assembly process and preparations will be much faster than the full turnkey assembly.

What Are The Benefits of Complete Turnkey PCB Assembly Services?

1. Take less time in PCB assembly

Fabrication depends on three stages: PCB prototype, PCB fabrication, and PCB assembly, which are primary in manufacturing printed circuit boards. Previously PCB manufacturing was complicated, and manufacturers sometimes faced many issues. But with the help of technology, the process is so smooth, which reduces the manufacturing time by half.

Complete turnkey PCB assembly is a fast solution for companies that need an effective form of electronic assembly. When the PCB turnkey Assembly was introduced, it reduced the time and provided overseas solutions to the clients, making the PCB assembly three times faster. With our complete turnkey services, get the best-printed circuit boards in minimal time!

2. Cost-effective PCB assembly

Turnkey PCB assemblies have given several ways of reducing the cost of manufacturing. You can get the finest printed circuit board delivered without any trouble that can take place during the procurement process. The best turnkey PCB assembly experts can prepare the printed circuit board with all its components and reduce manufacturing costs.

3. Versatile services for PCB assembly

If you switch to turnkey PCB assembly, you can get several services from the manufacturer that are efficient and cost-effective printed circuit board assembly methods. You can get a complete finishing for your printed circuit boards and can get these services:

- PCB prototypes

- High volume PCB

- Box Build

- Inventory Management

- Shipment to the end-user.

With turnkey PCB services, you can rely on us to take care of everything from the start to the final delivery process.

Choose Anpllopcb as your turnkey PCB assembly manufacturer

Anpllopcb is an ISO 9001 2015, ISO 13485 2016, and AS 9100 rev D certified company that focuses on the quality of printed circuit boards. Using the turnkey printed circuit board assembly from Anpllopcb, you can get the best complete turnkey services you need for your company’s operations.

If your business already has most of the parts required, a partial turnkey PCB assembly service can facilitate and quicken the PCB manufacturing process. This saves you money and time. Nevertheless, suppose you do not have the parts and are unsure where to order the right parts for your PCB design and manufacturing. In that case, a complete turnkey PCB manufacturing service will be a recommended option for you.

We Want To Work With You!

Get an Instant Quote to Compare Price & Turn Times Side-by-Side.We make it a point to make sure that what we deliver is exactly what you want.