OUR SERVICES

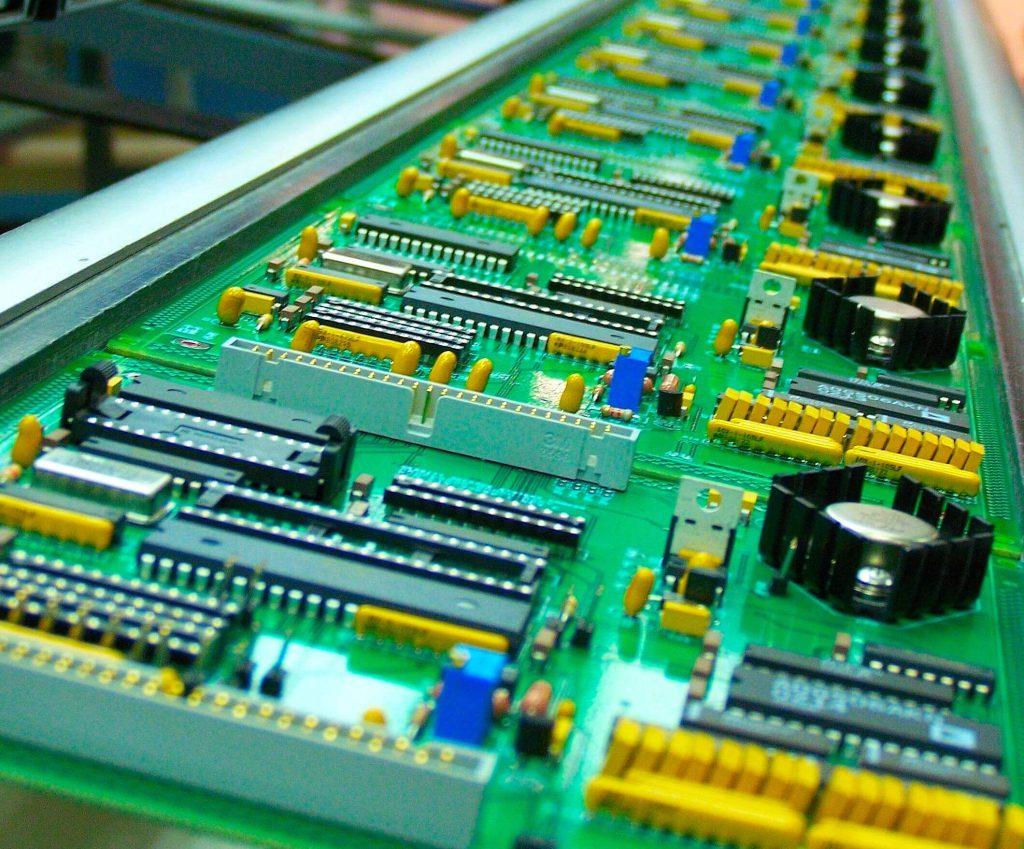

Quality Assured Through-Hole PCB Assembly

We provide through-hole PCB assembly services to meet various industries’ conventional lead assembly requirements. We provide single, double-sided, and high-density multilayer PCB Through Hole (PTH) circuit board assembly services to meet our clients’ low to mid-volume production requirements.

Through-Hole Assembly

The through-hole PCB assembly is one of the modern technologies which has replaced point-to-point construction mainly. It can restrict the available area for routing. We deliver thru-hole PCB assembly services to digital electronic companies that manufacture electronic devices like computers. Generally, it is needed for heavy equipment. Electrolytic capacitors and semiconductors generally need this kind of assembly. The thru-hole assembly can be used extensively as the breadboard sockets. Thus, engineers always look forward to making the through-hole assembly service.

Characteristics:

While through-hole mounting provides strong mechanical bonds compared to SMT techniques, the additional drilling required makes the boards more expensive. They also limit the available routing area for signal traces on layers immediately below the top layer on multilayer boards since the holes must pass through all layers to the opposite side. To that end, through-hole mounting techniques are now usually reserved for bulkier or heavier components such as electrolytic capacitors or semiconductors in larger packages such as the additional mounting strength, or for components such as plug connectors or electromechanical relays that require great strength in support.

Design engineers often prefer the larger through-hole rather than surface mount parts when prototyping because they can be easily used with breadboard sockets. However, high-speed or high-frequency designs may require SMT technology to minimize stray inductance and capacitance in wire leads, which would impair circuit function. Ultra-compact designs may also dictate SMT construction, even in the prototype phase of design.

contact us

Why Through-hole PCB Assembly?

The mechanical strength of PCB through-hole connections is higher than most surface-mount connections. In contrast, the bonding strength of PCB surface mount components does not exceed the multilayer PCB board surface’s bonding strength. With the miniaturization of devices, the solder decreases, and the connection strength also decreases.

Through-hole PCB technology process fixing components are most suitable for high-reliability products that require high-strength connections between multilayer boards. The surface mount device (SMD) is only set on the circuit board’s surface with solder, and the lead of the through-hole fixing component runs through the circuit board, and the part can withstand more significant environmental stress. Too much solder could get into other connections and cause a short. Too little, and you may not have a strong enough joint. Cold solder joints could break, and if you get the connection too hot, you may cause some damage to the components or the board.

Therefore, through-hole PCB assembly technology is usually used for military, automotive, and aerospace products with extreme acceleration, collisions, or high temperatures. Through-hole assembly technology is also suitable for testing and prototyping applications that sometimes require manual adjustment and replacement of devices.

Our Through-Hole PCB Assembly Service Features

- Single, double-sided through-hole PCB assemblies.

- Multi-layer PCB boards, varied dimensions, layers, and thicknesses

- Cost-effective PCB assembly technique

- Hand soldering

- Lead forming and trimming

- Rework, process, and verification

- Electrical testing is required for your plant floor environment

- PCBs assembled, inspected, and tested

We use through-hole placement techniques for radial and axial components for low-volume production. Due to their stronger mechanical bonds, these PCB assemblies can take higher environmental stress.

Potential Applications

Because of its unique benefits, through-hole technology has multiple possible applications. The investment of additional time and money required to complete through-hole PCB assembly makes it best for large components such as transformers, semiconductors, and electrolytic capacitors. The extra security it provides makes it a good option for any product that must withstand high levels of mechanical or environmental stress and high power and high voltage conditions.

Military and aerospace applications prefer thru-hole mounting for precisely these reasons. When safety depends on properly functioning equipment, taking the extra steps to through-hole technology critical components is necessary. Through-hole technology can also be useful for product prototyping, where the testing process routinely subjects completed units to extreme conditions.

Our Through-Hole PCB Assembly Services

Anpllopcb can fully provide prototype and small quantity, through-hole PCB assembly services at the highest quality level possible in a cost-effective manner.

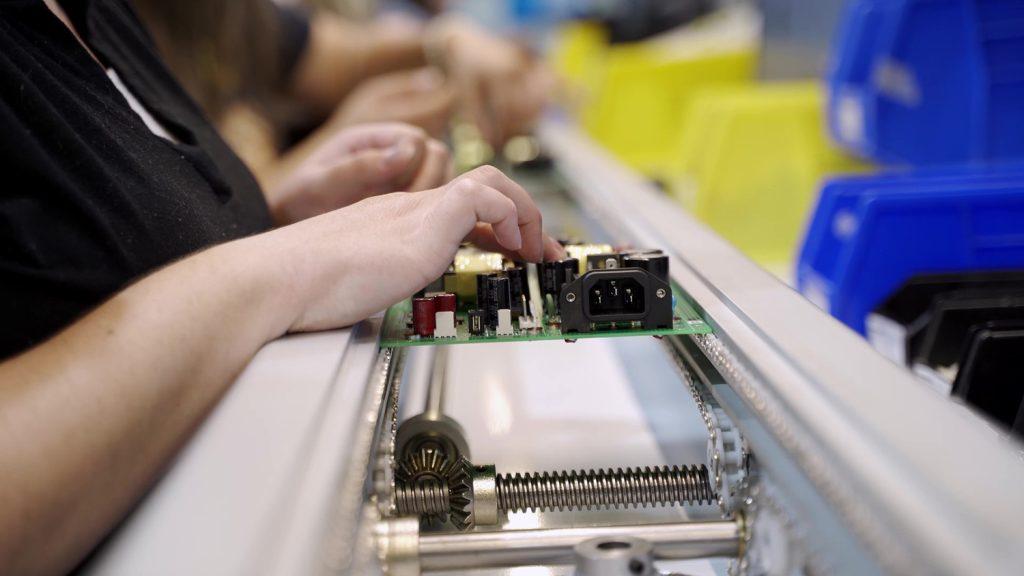

Automated and Manual Through-Hole Assembly

We use automated through-hole placement techniques for radial and axial components, preferably for small-volume production. The layout of the auto-placement area is intended to reduce material handling and labor. Our engineers use the manual placement technique to deal with compound through-hole assembly challenges. Wave-soldering is used for both Surface mount and Through-hole components, but we prefer to use it for simple through-hole components. In mixed technology boards, the first board is wave-soldered and then reflowed.

Through-hole mounting of components provides strong mechanical bonds compared to the surface-mount technique and gives extra space for the designer to route the tracks. However, surface mount components can allow for denser circuit configurations and utilize both sides of the board. Through-hole mounting is necessary for larger and heavier components, requiring stronger bonds for a robust connection. Our dedicated team procures our components through authorized North American distributors to ensure authentic, high-quality parts. Easy availability of all required components enables us to provide fast manual, automated, and combination through-hole assembly.

Our diligent staff ensures no compromise on quality since they are trained to follow all the inspection steps for low volume and prototype through-hole PCB assembly. We have a quality assurance team to monitor, inspect the processes and support continual improvement. We currently employ numerous advanced test equipment, including AOI Testing, Visual inspection, In-Circuit test, and optional functional tests to produce high-quality and cost-effective assembly.

We Want To Work With You!

Get an Instant Quote to Compare Price & Turn Times Side-by-Side.We make it a point to make sure that what we deliver is exactly what you want.