OUR SERVICES

SMT PCB Assembly

Providing solutions for all SMT PCB assembly Services, including rigid, metalcore, flex, and rigid-flex, too many across multiple industries.

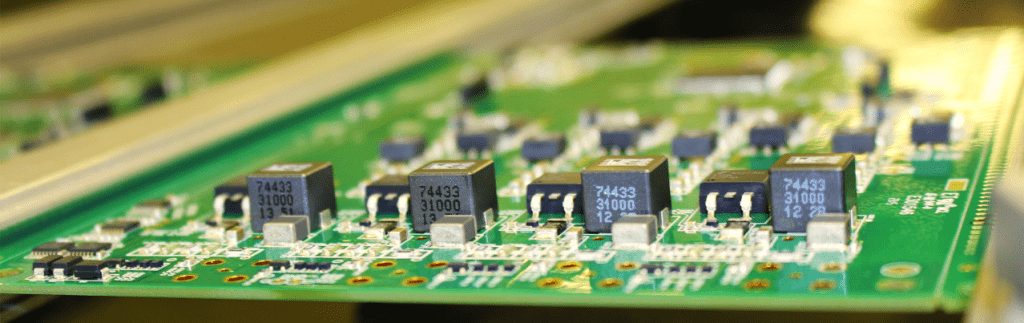

Surface Mount PCB Assembly

SMT is a flexible and powerful assembly process that has allowed manufacturers to produce modern devices with ever-smaller footprints. In SMT, all the different components needed for today’s devices are attached to the surface of the printed circuit board. SMT can be highly automated, so it’s a natural fit for clients who need circuit boards in high volume, but it’s also highly customizable.

Surface mount technology (SMT) is the most commonly used process in the industry regarding Surface Mount (SMT) PCB Assembly. Not without any reason, it allows for components to be mounted directly on the surface mount PCB. The technique lends itself to the miniaturization of assemblies, which is the order of the day. Also, SMT Assembly (Surface Mount Assembly) is known for its high mechanical strength. The SMT-printed circuit boards are a preferred choice for high-speed circuits.

Anpllopcb is a longstanding provider of surface-mount PCB assembly services for customers in various industries. We specialize in contract manufacturing and have extensive experience assembling electronics for various applications. We can assist with product prototyping and testing, contract manufacturing, and more with a broad selection of equipment and expert staff.

contact us

SMT PCB Assembly Process

1. Preparing the PCB and Initial Circuit Board Design

Assemblers use a solder paste printer to place solder paste in the desired location on each board before adding components to the board. Solder paste is a mixture of solder particles and a special flux. Heating this solder paste during reflow causes electrical connections to form. Manufacturers often use stencils and squeegees to ensure that solder paste is printed in the correct location on each circuit board. Jet printing is another option for prototype PCB assembly.

2. Placing Surface Mounted Components Components

After applying solder paste and inspecting it, the assembler carefully places the components on the board. Typically, these components are packaged in trays, reels, or tubes, so pick-and-place machines can use vacuum or gripper nozzles to pick up the components and position them on the PCB.

3. Reflow Soldering Process

The solder paste temporarily holds the components in place. Still, the electrical components are not fully attached to the unit, and electrical connections are not made until the PCB layout has been reflowed. In a reflow oven, the units are heated until the solder paste reaches a temperature high enough to form solder joints. This process needs to be carefully controlled, as the maximum temperature of the assembly may be close to that required to produce a good solder joint.

4. Inspection

Quality assurance inspection can occur at a few key moments in the SMT process, depending on the equipment used and the design requirements. Before components are attached, the solder paste is typically inspected to ensure no printing defects. Inspection is also common before and after reflow soldering.

SMT Assembly vs. THT Assembly

An electrical component mounted in an SMT assembly manner is a surface mounting device (SMD). In the PCB assembly industry, the SMT assembly approach has largely replaced the through-hole technology (THT) construction method of populating components, in large part because SMT allows for increased manufacturing automation which reduces cost and improves quality -it allows for more components for fitting to a given area, especially when electronic devices are in pursuit of size miniature. Both technologies can be used on the same board simultaneously, with the thru-hole technology (THT) often used for components unsuitable for surface mounting, such as large transformers and heatsinked power semiconductors.

The SMT component is usually smaller than its thru-hole counterpart because it has either smaller leads or no leads. It may have short pins or leads of various styles, flat contacts, a matrix of solder balls (BGAs), or terminations on the body of the component.

Advantages of SMT

There are many advantages to using surface mount technology, including the following:

A chief advantage of SMT is that it can attach very small components and do so at high densities. For this reason, SMT leads to overall smaller units than can be constructed with other manufacturing processes. With contact terminals instead of leads, SMT components can be miniaturized to the size of one grain of sand.

In the through-hole process, components can only be placed on one side of the board — the pins sticking through place a hard limit there. With SMT, though, components can be attached to one side and then the other, allowing for more complex circuitry without significantly increasing the overall unit size.

Through-hole technology requires the drilling of holes in the PCB. While this creates secure connections, drilling costs the manufacturing process. As SMT does not require drilling, it is often the more cost-efficient manufacturing process.

There are many manufacturing benefits to SMT that make it a highly automated process. Machines can conduct solder paste printing, component placement, inspection scanning, and reflow soldering.

With SMT, you can attach various components to circuit boards. Companies in various industries have deployed this assembly process because it enables them to customize boards for almost any application.

Capability of SMT PCB Assembly

Our capabilities in high-quality SMT printed circuit board assembly service span:

- State-of-the-art SMT Assembly line that ensures reliable boards.

- Production-ready components that improve turnaround times.

- Assembling single and double-sided SMT PCB of the following types:

- Ball Grid Array (BGA)

- Ultra-Fine Ball Grid Array (UBGA)

- Quad Flat Pack No-Lead (QFN)

- Quad Flat Package (QFP)

- Small Outline Integrated Circuit (SOIC)

- Plastic Leaded Chip Carrier (PLCC)

- Package-On-Package (PoP)

- Small Chip Packages (Pitch of 0.2 mm)

Our stringent testing protocols for surface mount assembly include the following:

- Automated Optical Inspection

- X-ray testing

- In-circuit Testing

- Functional Testing

Therefore, we ensure a high level of accuracy even with high-density Surface Mount (SMT) PCB Assembly.

Work with SMT Assembly Professional at Anpllopcb!

Anpllopcb’s PCB Assembly Process is carefully matched to your design and your specific constraints, so you can rest assured that your SMT parts will be soldered flawlessly every time. We will review the SMT PCB assembly design you submit during our DFM and DFA stages, and we might give feedback some suggestions, but you are always in complete control of the project. We will happily work with your engineers to produce exactly the SMT assemblies you need. We thoroughly review and follow each SMD component’s reflow surface mount soldering requirements for each assembly job we undertake. We have a very high yield as we implement precise control of the reflow soldering process.

We employ various verification and inspection methods to detect the joint soldering SMT quality, including repeated Visual Inspection, AOI, and X-ray Inspection. There is no way to perform a direct visual inspection for leadless parts such as QFN, DFN, and BGA packages. By using X-ray inspection, many issues with SMT soldering can be detected -this is important for BGA assembly projects.

We would be grateful to work with you on your PCB assembly project and offer whatever help we can, regardless of where you are in the design process. We can provide DFM advice from the earliest stages of your design. Once your project advances, we’ll give you quick turnaround times for prototypes and maximum flexibility for your production runs. Contact Anpllopcb now for a quick quote on your SMT assembly job!

We Want To Work With You!

Get an Instant Quote to Compare Price & Turn Times Side-by-Side.We make it a point to make sure that what we deliver is exactly what you want.