OUR SERVICES

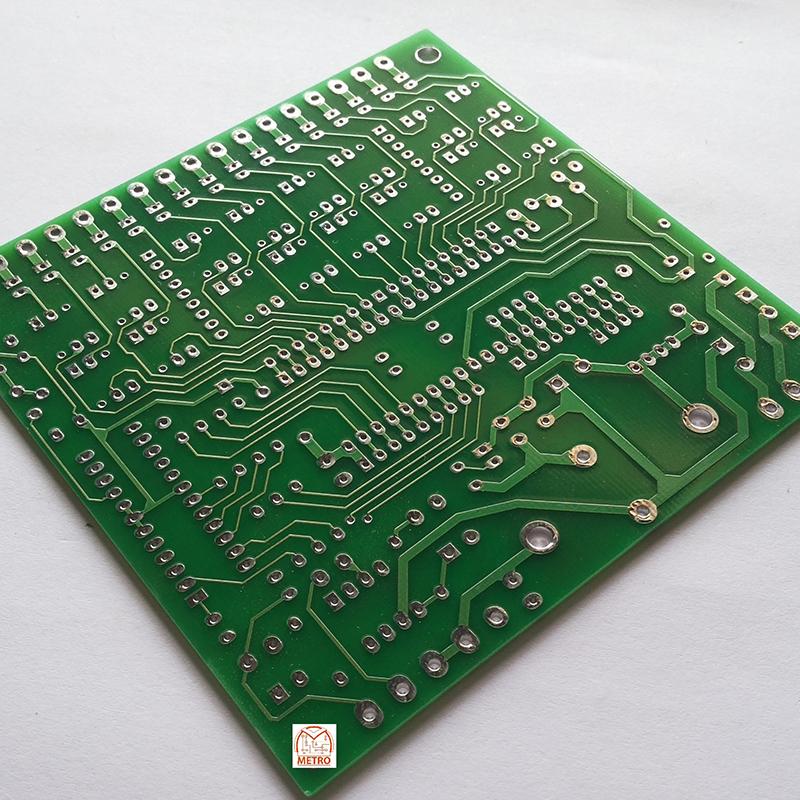

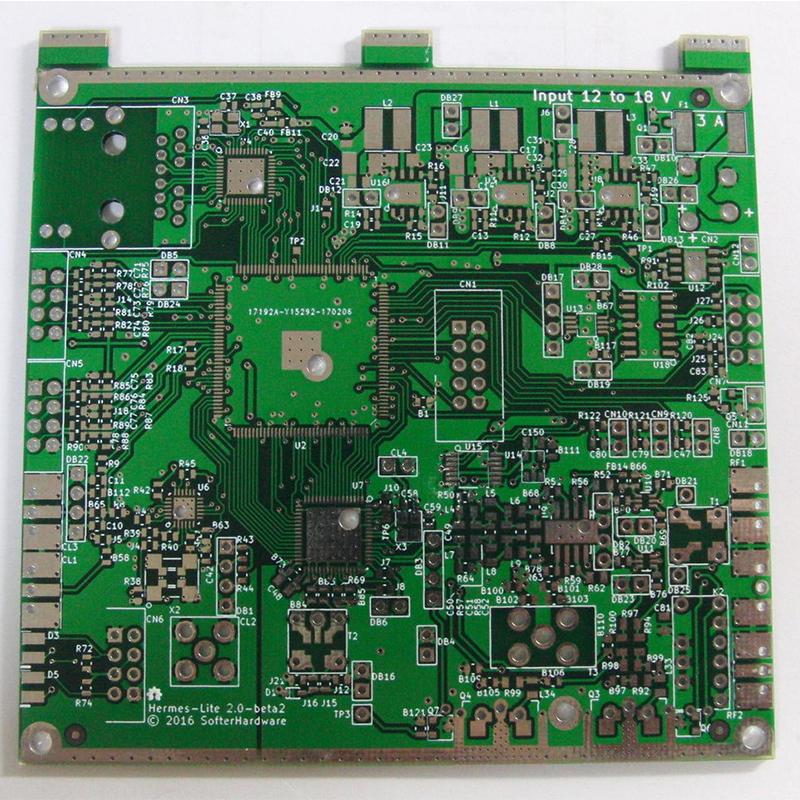

Rigid PCB Manufacturing

Get your custom rigid PCB exceptionally fast. Anpllopcb manufactures and assembles the highest-quality PCBs. Manufacturing, component procurement, and assembly are available.

Anpllopcb: A reliable Rigid PCB Manufacturer

When it comes to PCB manufacturing, Anpllopcb is a world leader and pioneer. Our PCB boards are of the highest quality and are very durable. So, our PCB offerings include Rigid PCB, Multilayer Flex PCB, and Rigid-Flex PCB. We have a very advanced technological setup that allows us to ensure customer satisfaction. Additionally, we have a dedicated R&D staff, and our customer support is always available. If you decide to work with us, you will have access to our valuable resources. Hence, you can manufacture electronic products by incurring minimum costs and saving valuable time.

As a rigid PCB supplier, we can help you with the following:

1) Project Evaluation

Our experienced engineers will extensively review and analyze your requirements. Afterward, we will help you with component selection, cost reduction, and feasibility reporting.

2) Development of Hardware

We have years of experience in developing complex hardware. So, our team will diligently develop the hardware and firmware you need.

Our team will come up with a pragmatic design for your product architecture. So, for this purpose, we will leverage our superior CAD technology.

4) Testing

Relevant testing is empirical when it comes to rigid PCB. So, we offer in-house testing and inspection services for all our products.

5) Certification

We comply with international standards, and we have relevant industrial certifications. We can readily offer RoHS, CE, and FCC certifications per your needs.

Anpllopcb Advantage

At Anpllopcb, we have more experience fabricating and assembling various PCBs- from rigid, Flex to rigid-flex PCBs. Irrespective of how easy or complex your requirement is, our state-of-the-art equipment and a team of experts are well-equipped to handle it. When you join hands with us, you also get access to a rich body of industry best practices that give you an edge.

We are extremely committed to offering quick turnaround times that help you go to market early. The fact that we offer prototype quantities to large production runs with the same unstinting focus on quality endears us to our clients. You can also count on us for turnkey services, and rest assured that you will get high-quality products.

All you need to do is to get in touch with our team and share your bespoke requirements. Our experienced team will share a custom quote and ensure that the PCB is fabricated to your needs.

All of this at the most cost-effective prices that ensure your project is competitive!

Get a quote for your rigid PCBs

Whether you need a basic single-layer circuit board delivered tomorrow, or a complex 30-layer mil-spec PCB using exotic metals, Anpllopcb can provide an instant quote and manufacture your boards in as fast as 24 hours.

- On-site inventory of the finest materials, up to 30 layers

- 1-day turn-times available

Build with the highest quality PCBs. Anpllopcb can help you efficiently manufacture and assemble your rigid PCBs.

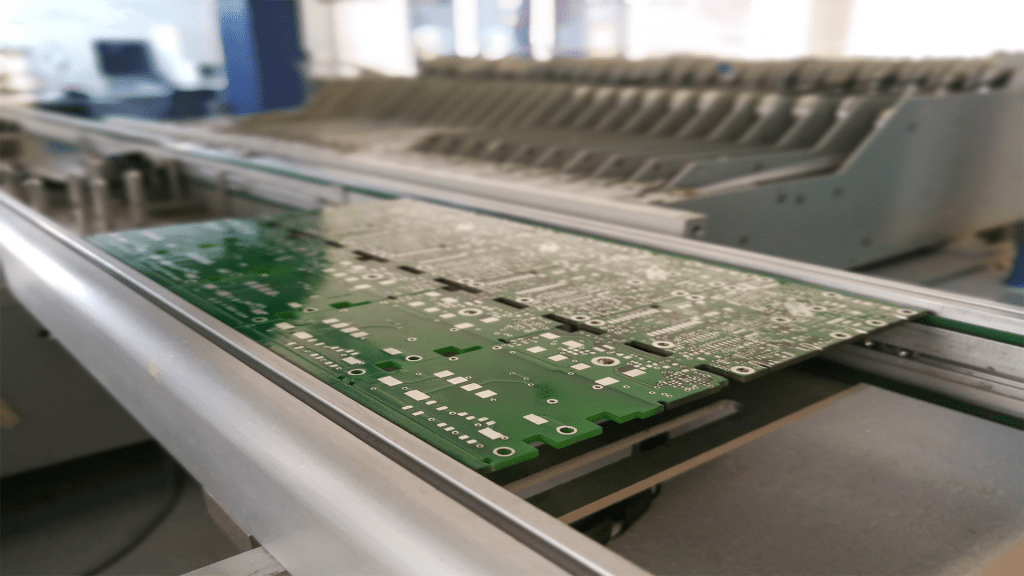

Rigid PCB Manufacturing process

We start with only bare-bone boards. Then we clean them by applying chemicals. So, after that, we apply photo-resistive films to them. This is because we want to ensure that the boards don’t incur damage of any sort.

We then lay down the respective circuit patterns on the board. So, we perform this process by applying UV rays on the board. This allows us to ensure that the circuit images transfer onto the board.

Then we perform etching to ensure that the circuit patterns remain on the PCB board. For this purpose, we use automatic handling machines and special chemical etching equipment.

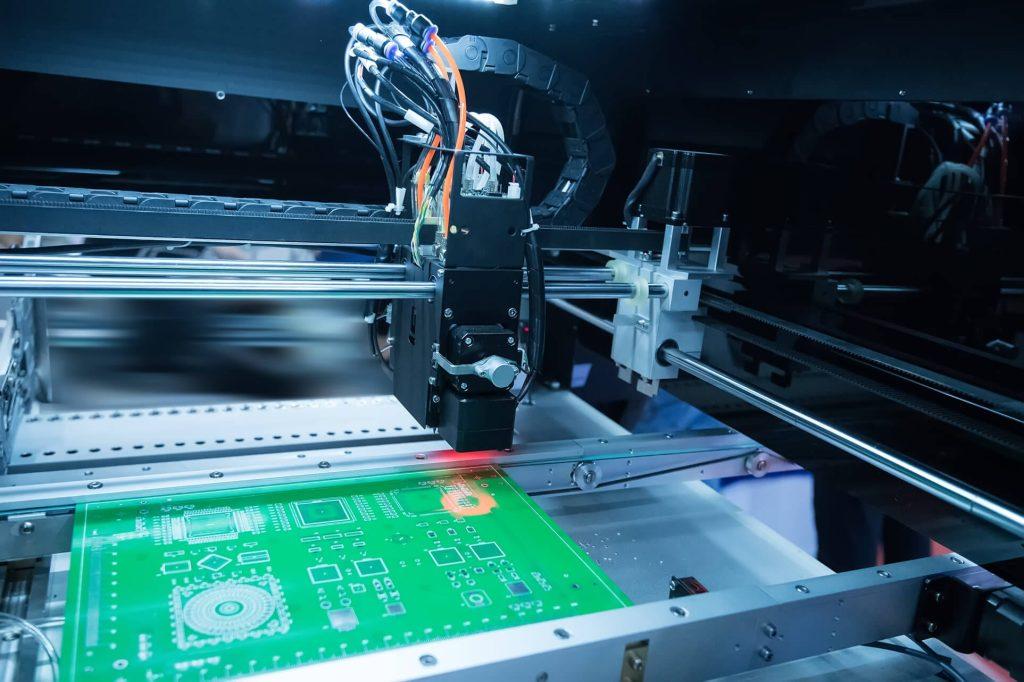

Then we start drilling holes over the circuit patterns. We must ensure that the holes have a certain size per the standard specifications.

Then we initiate the process of copper plating. So, in this process, we apply copper onto the board. Hence, it allows us to create electrical connections in multiple layers.

We then apply overlay laminate over the PCB. This allows us to protect the PCB and enhance its performance. So, we can perform this process both manually as well as automatically.

Stiffeners act as supportive elements, and we use them to prevent distorting and loosening. So, we have to use heat or pressure to apply stiffeners successfully.

The final step involves assembling the PCB. So, we often use PTH (Plated Through Hole) technology for mounting Rigid PCB designs. This step involves the application of lead through the drilled holes. We then solder the lead to the pads on the opposing side of the PCB.

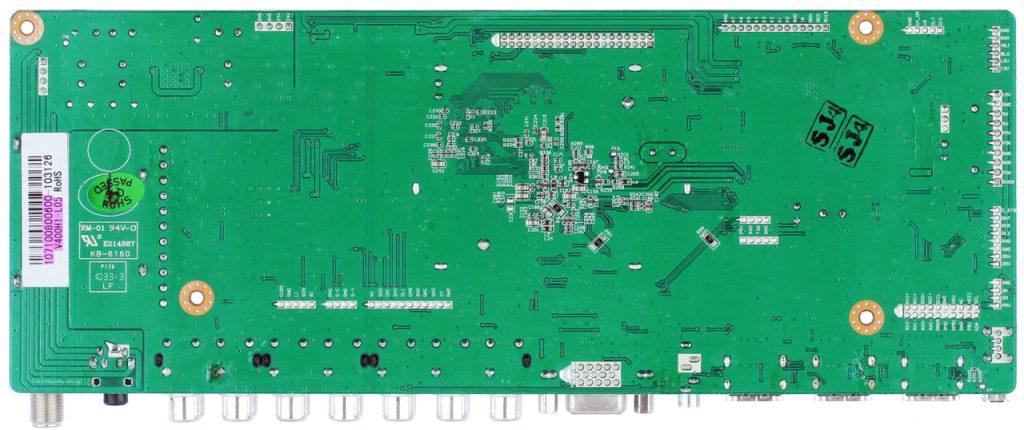

Characteristics of Rigid PCB

Characteristics of Rigid PCB are mainly summarized in the following points:

●Rigid PCB is a conventional PCB; it can not be twisted or folded into any shape because it has FR4 reinforcement, which is very useful for increasing stiffness.

●A computer motherboard is the best example of a rigid PCB with a rigid substrate material.

●Once a rigid PCB is fabricated, it cannot be modified or folded into any other shape.

●Rigid PCBs are cheaper than flexible PCBs and widely used in many electronic products.

Rigid PCB Stack UPs for Manufacturing

●Substrate Layer

The FR4 is the most common fiberglass as a substrate material to provide rigidity and stiffness to the board.

●Copper Layer

On top of the substrate layer, copper foil is laminated to the board with the help of added heat and adhesive.

●Solder Mask Layer

The solder mask is on top of the copper layer and used to avoid any damage if any conductive material comes into contact with the copper layer.

●Silkscreen Layer

The silkscreen layer is on the solder mask layer. White is mainly used for silk screen printing.

Types of rigid PCB offered by Anpllopcb

Anpllopcb is committed to providing high-quality rigid PCB. Anpllopcb offers the following types of rigid printed circuit boards to meet customer needs.

Single-sided PCB

Double-sided PCB

Multilayer PCB

We Want To Work With You!

Get an Instant Quote to Compare Price & Turn Times Side-by-Side.We make it a point to make sure that what we deliver is exactly what you want.