OUR SERVICES

Rigid-flex PCB Manufacturing

Apllopcb is a Leading Rigid-Flex PCB Manufacturing Services Provider With Broad Flex and Rigid Expertise.

Rigid Flex PCB Manufacturing Service

Anpllopcb Rigid-flex PCB board manufacturing solutions are custom designed for many top electronic industries. Fabricated with dependable high-standard quality control and reliability, our Rigid-flex Board is built to withstand the rigors of aerospace, Robot control, medical, and military applications. As a reliable replacement for wire and wire harness assemblies, rigid-flex circuits provide significant cost savings with no reduction in performance. Our PCB engineer team can assist you from your application’s early rigid-flex design stages to final production for all your flex and rigid-flex circuit needs.

Anpllopcb Innovation to Support Emerging Technology Trends

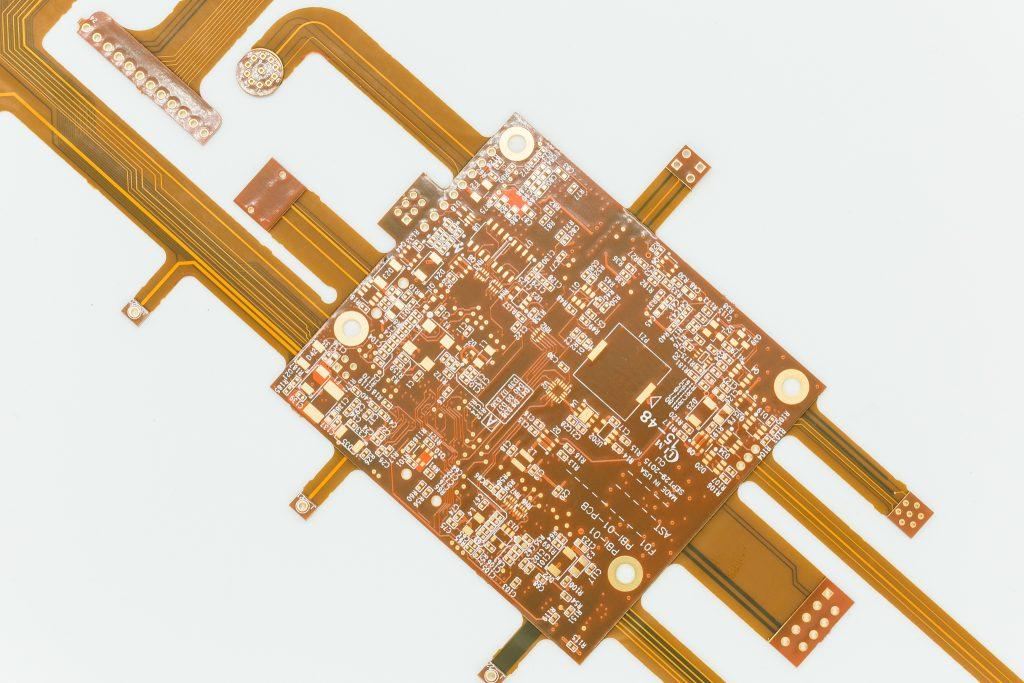

Rigid-Flex and Flex products provide reliable integration of multiple rigid printed circuit board (“PCB”) assemblies into a single PCB module capable of supporting assembly, space/weight savings, and mechanical stability.

Anpllopcb’s global team of engineers offers our customers design for manufacture guidance. We have industry-leading talent that has supported rigid-flex and flex-dependent designs from the prototype stage to end-of-life. We help customers improve their overall yield and find cost efficiencies wherever possible. This close collaboration results in the inspiring innovations our customers bring to market, enabling people to live and work better.

Our Capabilities

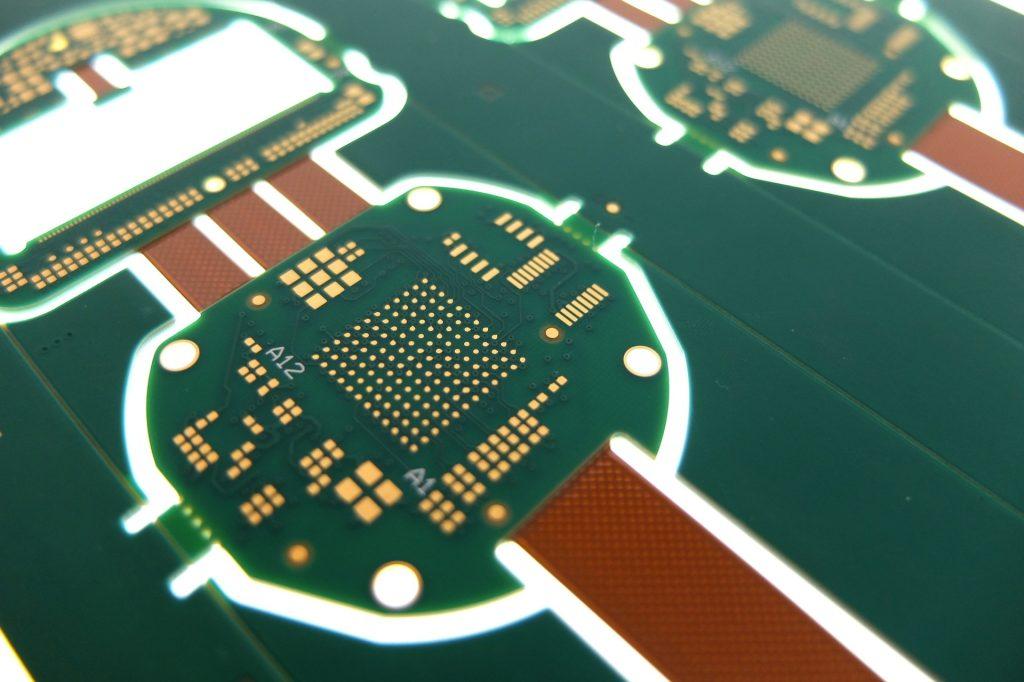

We work hard to get your rigid-flex PCBs to you quickly, provide the quantities you need, and meet your required specifications. We offer penalization optimum, which arranges your rigid-flex boards into large multi-unit panels you can easily break apart for use, and shielding, which minimizes electromagnetic interference. We can also use pressure-sensitive adhesives (PSAs) to secure sections of a PCB in place without using soldering.

What are Rigid Flex PCBs?

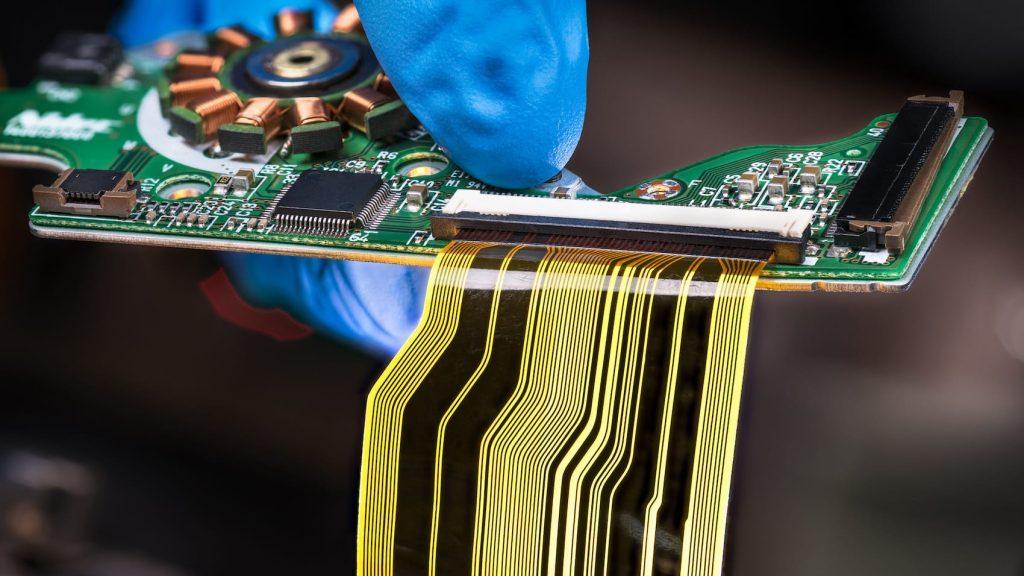

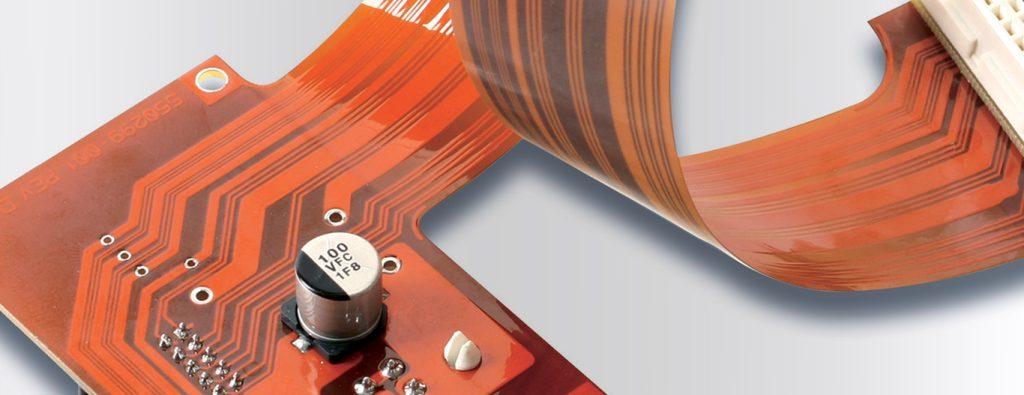

Multilayer rigid-flex board fabrication is those printed circuit boards that use a mix of rigid and flexible board technologies for a specific application. The majority of rigid-flex circuit boards are made of many layers of circuit substrates that are flexible and are attached to at least one rigid board internally and externally, depending on the application’s design. The designs of the flexible substrates are done to remain in the constant flex state and, during installation or manufacturing, are made to form a flexed curve.

The designs of the multilayer rigid-flexible PCB are usually more challenging in contrast to the rigid boards. This is because these boards are designed in a 3D space. This provides more spatial efficiency. With the ability to have a three dimensions design, the designers will be able to roll, fold, and twist the substrates of the flexible board to achieve the preferred shape.

Rigid-flex PCB Boards Design

The designs of Rigid-flex PCBs are a little more complex as these boards are designed in 3D, which allows the board to be folded or twisted to create the desired shape for the product. Designing a board in 3D means, they can offer greater spatial efficiency and can subsequently be used in special instances where space and weight reduction may be necessary, such as in medical devices.

Rigid-flex PCBs are usually thinner than other boards, meaning it’s a great option for any thin or light packaging needs your products may have. With thin copper layers and adhesive-less laminates, it’s a great small, thin, and light solution for your circuit design needs.

With our rigid-flex PCBs, we can offer cost-effective, high-quality, flexible products that can withstand bending stresses.

The Advantages of Rigid Flex PCB Technology

While this type of flexible circuit may be more expensive to design and produce, it does offer several important advantages. For instance, the reduced size makes it easier to fit more components into a smaller space. This can lower overall system costs. Additionally, because they require fewer interconnects and related parts and components, these flexible circuit boards can also be more reliable and require less maintenance in the long run.

As with all flexible circuit boards, the rigid-flex printed circuit boards will perform well in even the harshest environments, especially those featuring extreme heat. A rigid-flex board is also easy to test, making it well-suited for prototyping.

Benefits of Rigid-Flex PCBs

- Space requirements can be minimized by applying 3D.

- The board size and overall system weight can be reduced by removing the need for connectors and cables between the individual rigid parts.

- By maximizing space, there is often a lower count of parts.

- Fewer solder joints assure higher connection reliability.

- Handling during assembly is easier in comparison with flexible boards.

- Simplified PCB assembly processes.

We Want To Work With You!

Get an Instant Quote to Compare Price & Turn Times Side-by-Side.We make it a point to make sure that what we deliver is exactly what you want.