OUR SERVICES

offers Rapid PCB Prototyping for Your Research Work

PCB prototyping used to the nightmares of many electronics professionals. Anpllopcb now terminates the nightmares! We can get your first-try boards right in 24 hours!

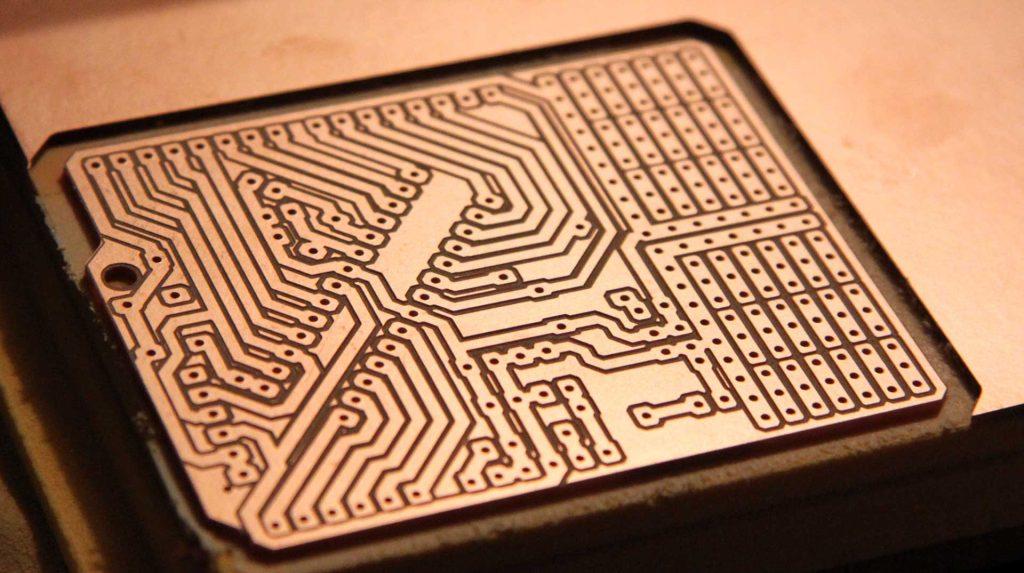

Prototyping PCB Technologies

Through a diverse portfolio of suppliers, we can offer nearly limitless capabilities for our prototyping PCB services.

Whether our customers need single or double-sided FR4 boards or very high technology blind and buried via boards, boards made with unique materials, Anpllopcb will be able to bridge your design concept with reality.

Our capabilities span a number of advanced technologies including thermal PCBs, microwave PCBs, heavy copper, rigid-flex PCBs, and flex PCBs.

Our engineering staff is available to consult you throughout the layout, build, and testing phases of prototype manufacturing, moving your application through additional prototyping stages or into production.

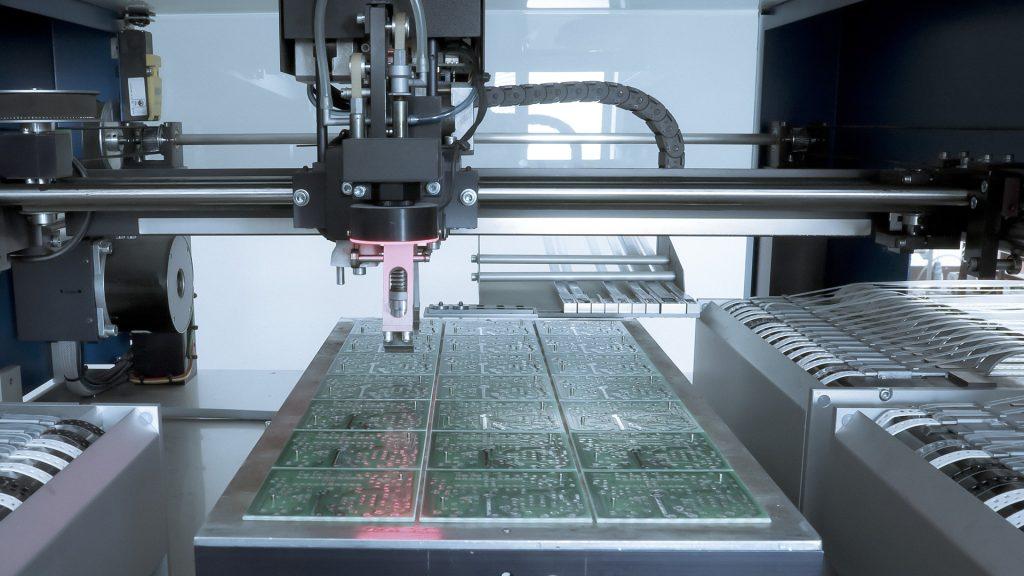

When you have finalized your design and the application of your prototype PCBs, we are also capable of a full production run for your product/application, including full turnkey assembly, with tighter PCB tolerances.

Moving a prototype into production with us will also give you the benefit of no additional tooling fees.

contact us

What is a prototype PCB?

Printed circuit board prototypes are used across all areas of the consumer and industrial electronics industries. A PCB prototyping stage helps confirm that a circuit design will work as intended once the components are soldered in place on a real board. In short, a circuit board prototype provides a robust pre-production proof of concept.

A prototype PCB is often a simpler, more basic version of a finished production board, typically offering fewer advanced features and design flourishes. However, it needs to be an accurate, high quality and fully functional test version of the finalised circuit. At this stage, prototype PCB assembly should mirror the basic design, function and component load-out of the finished production run as closely as possible.

Mistakes or oversights at this stage can prove costly if not corrected before moving on to the full batch PCB manufacturing stage, so it’s extremely important to get your PCB prototyping done right. Fast turnaround circuit board prototypes are also of huge value to our clients: the earlier in the process we can observe and correct any potential issues, the more time and money you’ll save on delivery of the finished product.

What’s involved in delivering a PCB prototype?

Developing prototype circuit boards and component layout is a way of checking for bugs and issues on a ‘live’ working model of your design. It’s often used as a follow-up stage to a solderless breadboard version, although a skilled engineer will be perfectly capable of producing an accurate circuit board prototype from the raw data files. Breadboard circuit tests use clip-in components to test the basic layout and behaviour of a circuit under current. Whether or not you’re using breadboards as part of the overall design process, they’re not seen as a sufficiently robust test on their own. In order to move forward to the full PCB manufacturing stage with confidence, you’ll first need to produce a properly assembled and soldered prototype. Prototyping should always be overseen by an experienced technician who knows exactly what they’re doing. It’s a vital step in the delivery of a full production run for a completed bespoke PCB project, but it’s often a step that needs to be completed to a tight deadline.

PCB Prototyping Benefits : Low Volume Prototypes, High Touch Service

Building a low volume of prototype circuit boards at a high standard is absolutely critical prior to costly production runs of hundreds or thousands of boards. Prototyping various iterations will catch costly errors and help refine your product design to achieve more economical final applications.

With a prototype run, you can quickly test, diagnose and correct design mistakes or functional miscues, catching errors that would be far more expensive, in both time and finances, to remediate in the long run.

Why might clients need a fast PCB prototyping service?

There are a number of reasons a client may want a printed circuit board prototype delivered quickly after finalising their circuit design. These can include:

Peace of mind at every phase of a project, and especially prior to moving forward with a finalised design to the full batch production stage

Reduced development timelines, helping lower overall project cost while also speeding up your time to market

Pressing deadlines – these can come either from customers for faster product supply, or to meet tight booking and shipping timescales for upcoming industry showcases

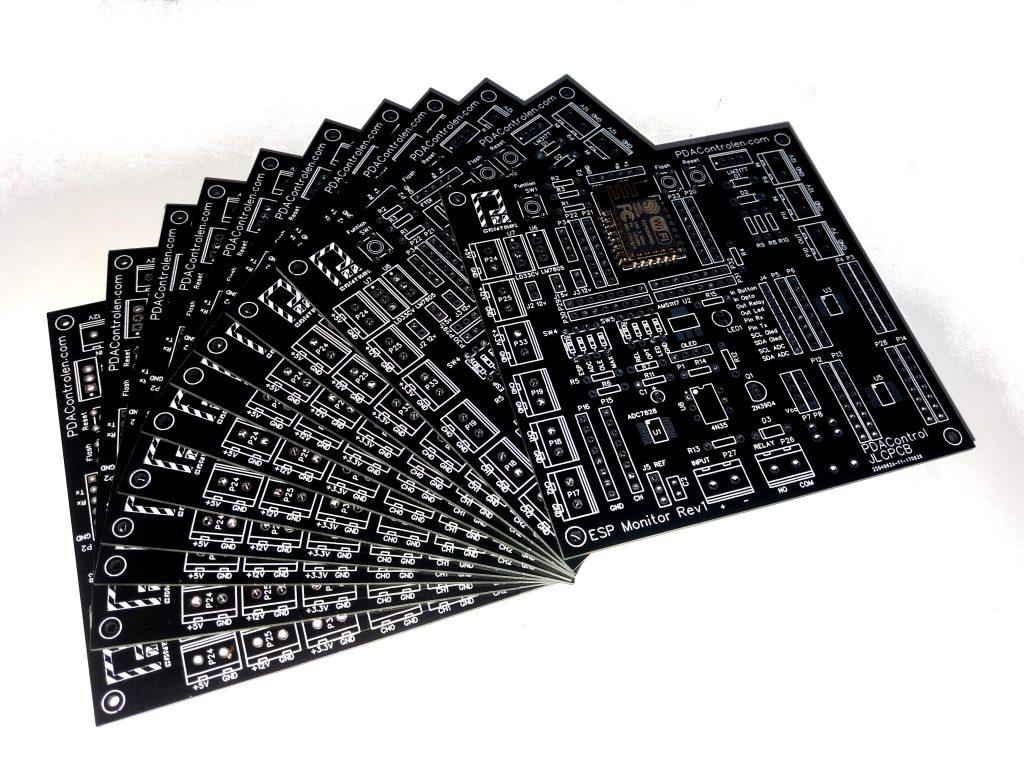

Types of PCB Prototypes

Different types of PCB prototypes are applied to test different aspects of the PCB design. Over the course of a project, a design team may use multiple PCBs at various stages of the design process. Some of these PCB prototype types include:

Visual Models: Illustrate the physical aspects of the PCB design, and show the overall shape and component structure. These are usually the first prototypes, which are used to communicate and review the design in a way that is easy and affordable.

Proof-of Concept Prototype: Just simple printed circuit board prototypes that focus on replicating the primary function without carrying all fabrication process of the final product. This kind of prototype circuit board is primarily to show whether the design concept is viable.

Working Prototype: the board contains all of the planned features and functions of the final product. It is used to identify weakness or problems in the design, and rarely represent what the finished product is going to look like.

Functional Prototype: This prototype is close to the final product as possible, provides the most accurate idea of what the design will look like and how it will work, with some basic material difference to keep prototype board costs low.

Engineers usually work through this list from top to bottom throughout the PCB design and verification process at prototyping stage.

Accurate and Reliable Prototypes

Having an accurate, reliable PCB prototype makes it much easier to solve design issues throughout the development process. Quality PCB prototypes accurately represent the functionality of your final product, allowing designers to see and test the following aspects:

- PCB design: Prototyping enables designers to catch flaws early in the development process, and the more accurate the design, the more accurate the identification of the flaw. This helps minimize design costs down the line, while also reducing the project timeline.

- Functional testing: What works in theory doesn’t always work in practice. Accurate PCB boards will help assess the theoretical values of the board to see if they show up in the practical values. This allows any differences in value to be checked, updated and potentially reevaluated.

- Conditional testing: The real world is a brutal environment for products, so it is essential that PCB products go through appropriate testing to ensure that they will survive environmental conditions. For example, prototypes typically undergo temperature variation testing, power variation testing, shock resistance testing and more.

- Final product design: PCBs are usually incorporated into a final product, and prototypes help determine if the planned product or packaging need to be adjusted for the final PCB design.

For these purposes, having an accurate PCB prototyping will help make other processes significantly easier, and will better prepare design teams for what to expect when they begin production runs.

Why choose Anpllopcb for your next PCB prototype delivery?

When you request any aspect of PCB prototype design or manufacturing service from Anpllopcb, you’ll benefit from some of the fastest data-to-delivery times in the sector. This means fast circuit board prototypes for proof of concept ready in as little as 8 hours, or fully manufactured boards produced within 5 days.

As leading PCB prototype suppliers and prototype circuit board manufacturers, we always stand by our accurate and conscientious work – and we’re happy to guarantee your satisfaction.

Our professional tech team is highly trained and qualified in all aspects of PCB production, including reverse engineering projects and blank board manufacture.

For more detailed information about any area of our end-to-end PCB services, please feel free to browse other areas of our site. If you’d like to speak to a member of our team directly about an upcoming project – including under fully confidential NDA agreements where required – then don’t hesitate to contact us today.

We Want To Work With You!

Get an Instant Quote to Compare Price & Turn Times Side-by-Side.We make it a point to make sure that what we deliver is exactly what you want.