OUR SERVICES

One-stop PCB assembly services

Anpllo offers various PCB assembly services, ranging from components procurement, fabrication, circuit board assembly, testing, and delivering the best quality end products to our customers.

PCB Assembly Services

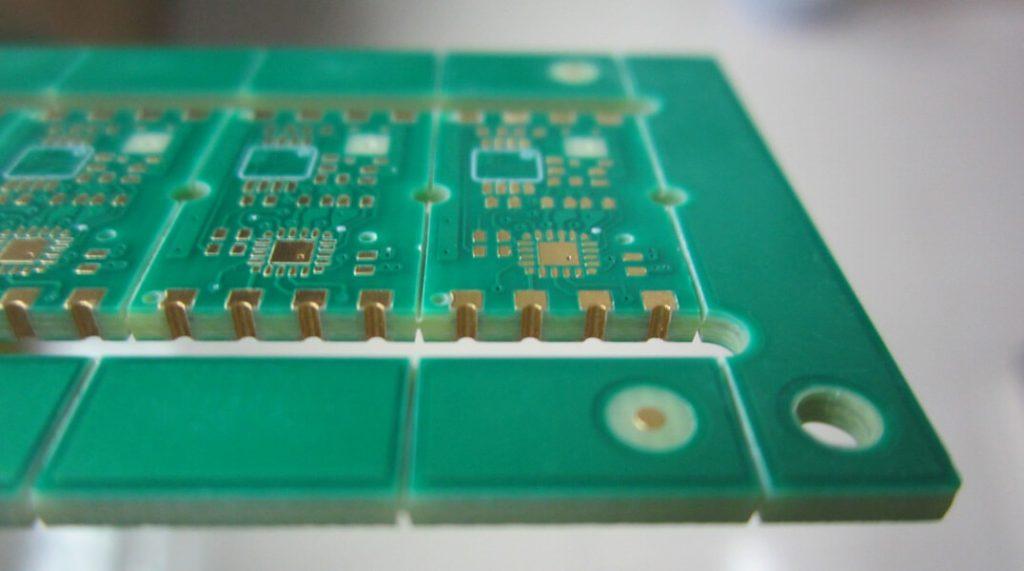

Anpllo has been a partner to businesses in various industries and sectors. Printed circuit board (PCB) manufacturing is one of our core service offerings. our technical and production capabilities establish us as a leader in advanced PCB assembly services.

We are an electrical assembly company specializing in short-run productions of 50,000 units or less. We offer comprehensive inspection, testing, and quality control services to help you create products and prototypes that meet your requirements.

Fast, reliable, and repeatable PCBA Manufacturing services from Anpllo maximize quality and reduce cost!

Anpllo turnkey PCB assembly services, include prototype board design and assembly and medium-to-high-volume printed circuit board assembly.

From simple single-sided assemblies to complex densely populated fine pitch and BGA surface mount assemblies, the Anpllo engineering team offers customized PCBA manufacturing solutions using our advanced production equipment.

Anpllo Assembly capabilities

SMT Assembly, BGA Assembly, Through-Hole Assembly, Mixed Assembly, Rigid Flex PCB Assembly Services, Electro-Mechanical Assembly, Box Build Assembly, Product Assembly, and Cable Assemblies. Compliant with many standards, including IPC 610 Class 2 and Class 3.

The PCB Assembly Process: Prototyping and Custom Design

The early stages of PCB production are often the most challenging if product manufacturers start developing independently. We can help make outsourcing production a practical choice for your product’s quality. Our experts can consult with your design team and plan a custom PCB around your specifications, including:

- How the product functions and what performance benchmarks should be met

- Environmental factors the electronics must withstand

- The price and quantity

- Any agency standards of working within

We generate a competitive quote for the project based on our discussions around these points and more. If no images have been made, we can create drawings to envision how the PCB will be assembled. We begin working with a small number of parts to build the circuitry and hardware of a prototype PCB.

Our goal is to exceed your expectations with the quality of the unit’s performance. Through multiple iterations and two-way feedback, we move toward a finalized design and prepare to increase production. We also perform rigorous testing to verify that the newly produced PCBs function as expected.

1. PCB Assembly Process Overview

- Surface Mount Technology (SMT) – SMT is mounting the electrical components directly on the PCB surface. Leads are soldered on the PCB surface directly instead of using hole mounting. We are known for our accuracy and for following the right SMT techniques to yield best-in-class SMT PCB assembly for electronic devices of all sizes. SMT is beneficial where there is limited space.

- Through Hole Technique – We provide end-to-end Through-hole assembly services from the prototype stage to production. We adhere to international standards, and our services comprise manual techniques for handling complex assemblies and automated techniques for small-volume production. THT provides strength to the components using the state-of-art wave soldering method.

- SMT and THT Assembly capabilities include –

- Full Through-hole Assembly Line

- Low to High Volume Production Assembly

- ESD Controlled Area

- Single and Double-sided Assembly

- Mixed Technology – We render mixed assembly services with Surface Mount Technology (SMT) performed first, followed by Through-Hole-Technique (THT). We ease the process in mixed assembly technology by selecting the optimal blend of layout and raw materials.

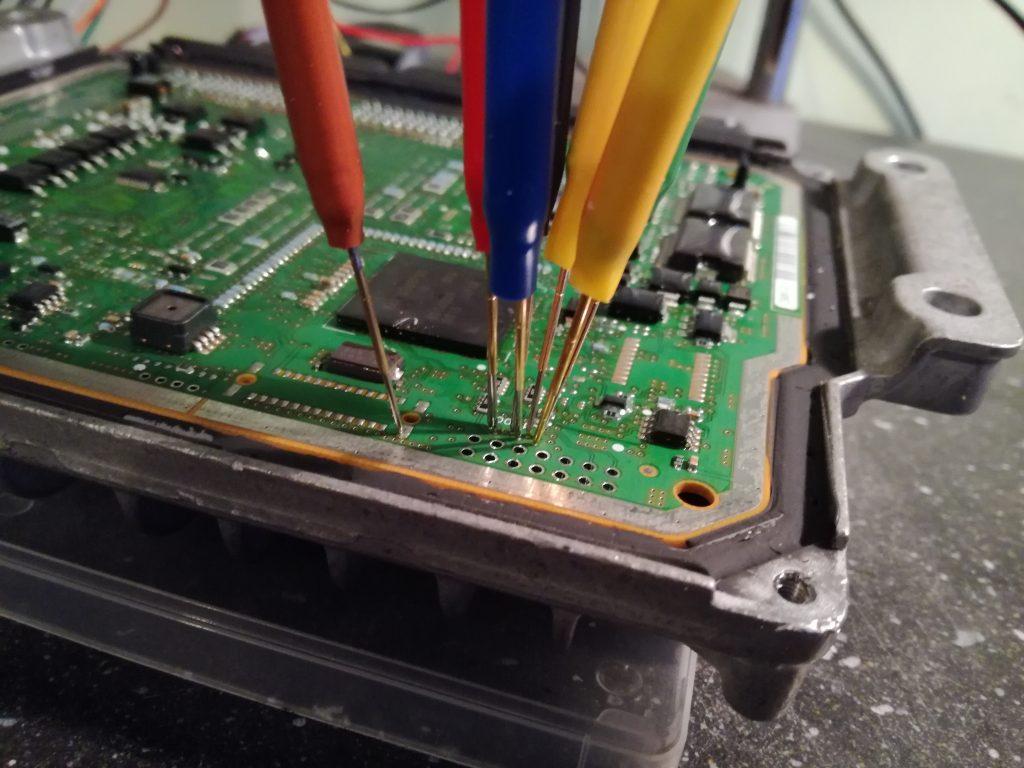

2. PCB Assembly and Design Processes: Through-Hole

Thru-hole PCB manufacturing is an older alternative to surface mount technology still in use in various applications. Unlike SMT devices, it requires drilling a hole into the board where leads can be attached. This allows for stronger bonds and, ultimately, more durable products.

During the through-hole assembly process, component leads are inserted into the drilled holes based on their position and polarity. Once an assembler determines everything is in place, they secure each component with heated solder paste. The solder cools and hardens, which creates a high-strength bond. While through-hole manufacturing was done manually for years, technology advancements have sped up the process and allowed for automation in soldering and assembly.

3. PCB Assembly Testing Capabilities

Full-Range Testing Capabilities – We perform extensive tests and inspection processes on our builds to ensure the highest quality standards.

Flying Probe Testing – We use it for low-volume and prototype circuit boards due to its ease of use in programming to validate line setup without additional cost and time. Our qualified testing team provides you with high-fault coverage benefits in a quick turnaround time.

ICT Testing – We use it on mature products to detect parametric, design-related, and component failures. ICT Testing takes lesser time to perform when compared to Flying Probe Testing.

Functional Testing – We perform this at the last stage of manufacturing on the finished products before they are shipped. We validate the PCB behavior, functionality, and features to keep it defect-free.

Choosing the Right Process for Your Application

Surface mount technology PCBs are faster to produce, making them the best choice for commercial applications. SMT manufacturing is the only way to manufacture certain small items, allowing for more compact spacing between components.

While requiring more time to produce, thru-hole circuit boards are more durable and easier to modify if necessary. The soldering strength makes through-hole circuit boards the preferred choice for harsher environments in many industries, such as military and aerospace.

Like the PCB business, our PCBA services also specialize in prototyping and small-volume production, making Anpllopcb the one-stop destination for board fabrication and assembly. This arrangement makes your R&D work easy and time-saving. Our professional engineers and technicians will work closely with you through our customer service people to ensure the best quality and quickest possible lead time. Fulfilling thousands of orders daily from around the world, we have established ourselves as the leading supplier of PCB and PCBA services for our consistent quality and excellent services.

PCB Assembly FAQs

Printed Circuit Board Assembly is the process of soldering electronic components onto boards. They can be installed using surface mount technology (SMT) or through-hole technology. You can use both also.

We can connect varied electronic components mechanically by using different conductive pathways, traces, and tracks. It also includes different components to be etched from laminated copper sheets and put onto a non-conductive substrate. Finally, the component leads are attached to the PCB layout with soft metal soldering.

PCB assembly services have become indispensable with the surge in the consumer electronics like laptops, gaming consoles, mobile phones, televisions, etc. These devices need electrical components which are assembled using a PCB. One needs efficient and precise PCB assembly services for their electronics to work as anticipated.

Our standard printed circuit board assemblies are of the following specifications – FR4, 1oz copper weight, white silkscreen, 1.6mm thickness, lead-free (if required), green solder mask.

We focus on the prototype or layout to reduce the additional cost you may encounter later. The PCB assembly price costs can also be reduced by taking care of the following elements like raw material, board thickness, copper thickness, min hole size, total hole quantity, layer counts, etc. You can see how you can optimize these to reduce the overall costs.

It depends on the size of your PCB. One board differs from the other, and so does the cost. Our team will help you find the best possible solution for your needs. Size, number of layers, board laminate type, and boards required impact the cost.

We have been certified to ISO 9001:2015, AS9100 rev D Certified, RoHS, and ITAR, and also compliant with the US Department of Commerce’s Export Administration.

Of course. We do partial PCB assembly for both consigned/ kitted orders and turnkey.

You can contact us when you see any issues on your loaded boards. We will dig into the issues, find the root causes, evaluate them, and repair them as required.

We Want To Work With You!

Get an Instant Quote to Compare Price & Turn Times Side-by-Side.We make it a point to make sure that what we deliver is exactly what you want.