Healthcare & Medical PCBs

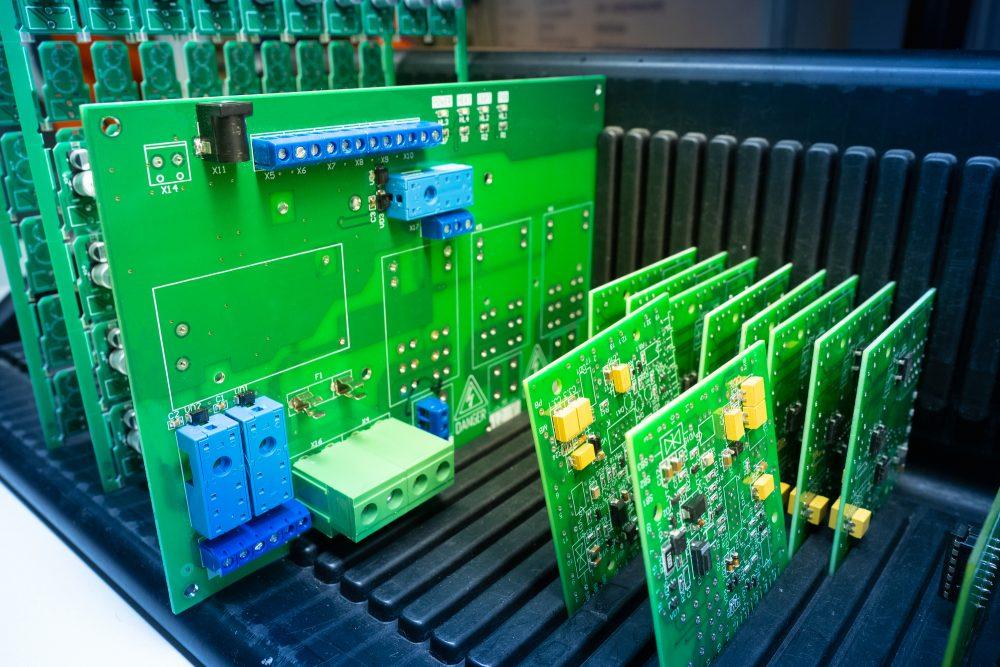

Anpllopcb supports multiple medical field devices, including blood centrifuges, regulator valve monitoring, patient calling stations, smart patient beds, and medical center equipment GPS tracking systems. Anpllopcb circuit card assemblies are present in hospitals, clinics, hospices, and almost every caregiving facility. The medical industry demands high reliability, consistent dependability, and the constant ability to fulfill customer, patient, and medical professional expectations.

Medical PCB Manufacturer and Assembly Services

Electronic devices in the medical field require high precision and accuracy with long-term life cycles and extreme reliability. Medical PCB manufacturers are strictly required to meet quality and sanitary control. It is an additional challenge if the device includes a printed circuit board (PCB). You can minimize the risk by partnering with Anpllopcb. We are an industry-leading medical device circuit board manufacturer. Anpllopcb has been offering medical PCB assembly services and contract manufacturing. We strictly follow all the required standards during the PCB assembly process. As a result, we produce a PCB that ensures your medical device works efficiently and is safe to use.

Highlights of Medical PCB Assembly Services at Anpllopcb

The following PCB manufacturing and assembly capabilities have contributed to our growth and made us one of the leading PCB assembly service providers.

- Types of medical PCB assemblies: Being an expert in the circuit board assembly process, Twisted Traces assembles different types of PCBs, including multilayer PCBs using rigid, rigid-flex, and flexible boards, depending on the requirement.

- PCB Materials We Work with: At Twisted Traces, we work with PCB materials such as Standard FR4 Tg 140°C, Tg 170°C, and Tg180°C, Copper Core, and Aluminum core. We create medical PCBs using RoHS-compliant and high-temperature materials.

- Surface Finish Options: We can provide PCBs with RoHS-compliant surface finishes such as Hot Air Solder Leveling, Lead-Free HASL, Immersion Tin, Immersion Silver, Electroless Nickel/Immersion Gold, and many more.

- Advanced PCB Manufacturing: With compact-sized medical devices gaining popularity, we help our clients minimize their device footprint by implementing our advanced PCB manufacturing expertise, such as:

- Fine Pitch, BGA & Micro BGA placement

- ESD, moisture, sensitive, FIFO procedures

- Blind Vias, Buried Vias & Microvias

- Via tented/covered with resin, Via plugged/filled with resin.

a passion for innovation

Your organization requires like-minded partners looking to push the limit of what’s possible. Our factory management systems are designed with FDA regulation in mind, allowing us to set the standard for compliance while creating market-leading innovations in crucial solution areas, including connected medical devices, energy delivery systems, fluid management, and more.

The testing standards we follow for Medical PCBs

We perform constant testing at each step of the manufacturing process to ensure the reliability of the Medtech circuit boards.

- Automated optical inspection (AOI): AOI captures images of the PCB with either a single 2D camera or two 3D cameras. The captured image is compared with the schematic. If the board does not match the schematic, the board is sent for manual inspection.

- Solderability test: Ensures that the solder joints are reliable.

- Ionic contamination testing: Ionic contamination testing is performed to detect ionic residues resulting from the fabrication and soldering steps.

- Peel test: Determines the strength required to peel the laminate from the circuit board.

- Micro-sectioning analysis: The inspection is carried out to determine the circuit board’s quality and to spot internal failures.

- Flying probe test: Test probes move from test points to other test points and check for opens, shorts, and other issues.

- Time-domain reflectometer (TDR): TDR impedance measurements are essential for ensuring signal integrity. It also checks for electrical discontinuities in connectors or any other electrical path.

critical engineering capability

Your engineering team has significant experience in contract manufacturing for the medical device and diagnostic industry and decades’ worth of experience in Class II and Class III production support. Our engineering team provides our customers with superior prototyping, design, and engineering services such as, but not limited to, computer-aided engineering (CAE) and manufacturing (CAM), design for manufacturability (DFM), and design for procurement (DFP).

Quality delivery of the product is the number one objective at Anpllopcb. Therefore, our Test Engineering Group does product testing throughout the manufacturing process. We ensure that all our products, whether printed circuit boards, custom cables, wire harnesses, or complete box/sub-assembly builds, are put through a broad range of rigorous engineering analyses, such as measurement and failure, fatigue, and stress testing. Test engineering services provided:

| Test planning and development | Product specific functional testing | |

| Test fixture development and build | Flying Probe capability | |

| Cable & Harness testing for shorts/opens | Manufacturing Defects Analyzer testing | |

| IC programming | On board programming | |

| Automated Optical Inspection | X-Ray Inspection |

complete contract manufacturing

Anpllopcb delivers a lean manufacturing contract manufacturing option to the medical device industry. We offer manufacturing from prototyping to volume builds in printed circuit board assembly, custom cable and wire harnesses manufacturing, and complete box and sub-assembly builds.

In PCB assembly, we have significant experience in flexes and traditional rigid board, single or double-sided, multi-layered, automated SMT, and special hand-working options, including through-hole. Our assortment of soldering options, board material options, and conformal coating options can meet any medical design specification needed.

Our Cable and Wire Harness capability can deliver cable and wire from 30 to 2 gauge, lengths from .5 inch to 500 feet, and in various materials, such as braided, mineral insulated, molded, over-molded, neoprene molded, semi-rigid, and shielded. We deal in most cable types: coaxial, coaxial ribbon, flat, braided, multiconductor, and pigtail. Wire lead and cable assembly for your medical device are our expertise.

A competitive advantage of being both a printed circuit board assembler and a custom cable manufacturer is the ability and technical know-how to build a complete electro-mechanical box and sub-assembly. Our technical expertise and state-of-the-art equipment mean fast prototyping, the quick volume builds, and high-quality results to the medical device industry.

Contact us to find out how you can put Anpllopcb’s manufacturing services to work for YOU!

We Want To Work With You!

Get an Instant Quote to Compare Price & Turn Times Side-by-Side.We make it a point to make sure that what we deliver is exactly what you want.