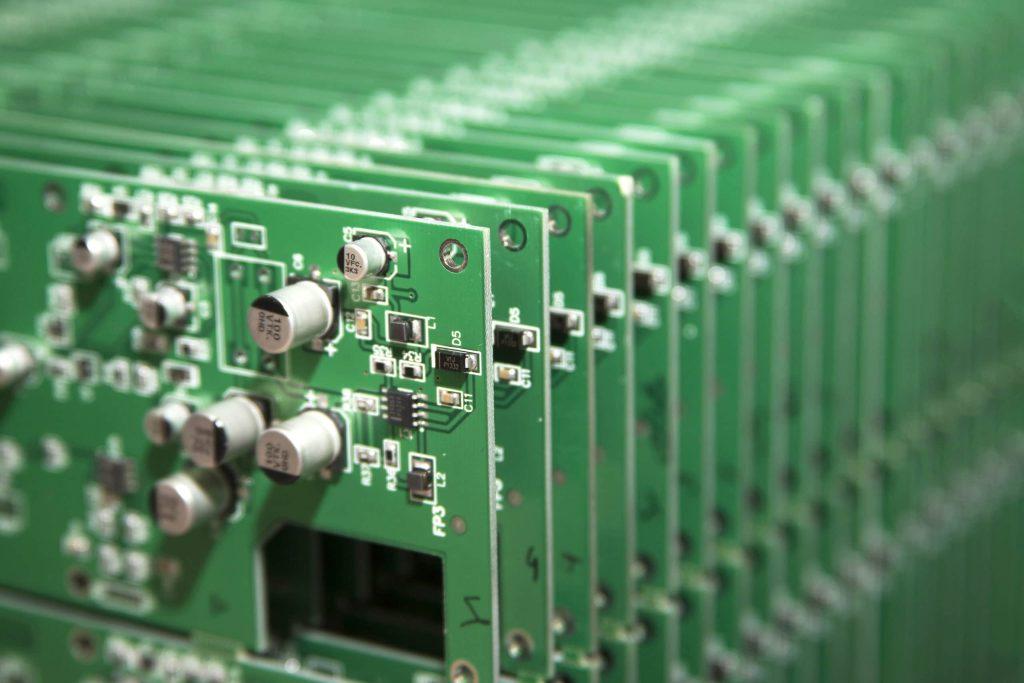

Industrial Manufacturing PCB Services

PCBs used in manufacturing and industrial settings are created specifically for always-on functionality. Whether you need a flexible PCB with high tensile strength or a standard technology PCB strong enough to last through hundreds of thousands of heating cycles, Anpllopcb boards are the industry standard for reliability.

Industrial PCB designs and industrial PCB manufacturing must follow strict industrial SIL and IEC standards.

- Layer counts up to 30 layers

- Board thickness up to 0.25″

- Panel dimensions up to 12″x18″

- Impedance tolerance -/+ 5%

- Laser drilling as small as .0025″

- Mechanical drilling as small as .005″

- Solder mask feature tolerances as small as .0005″

- Min trace and space as low as .0015″

- Blind and buried vias

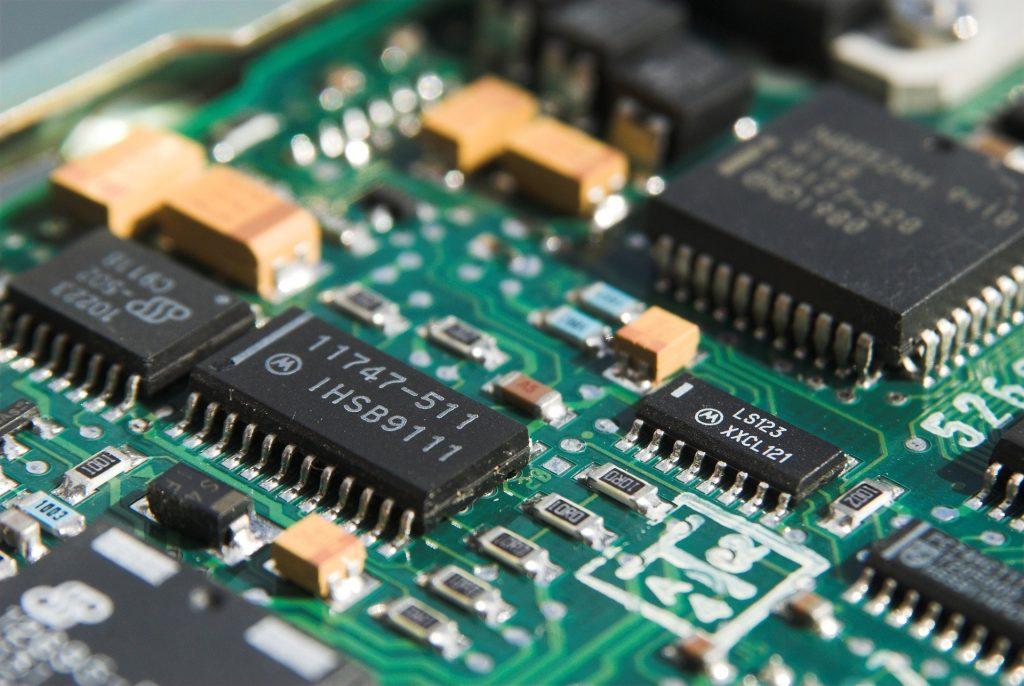

Industrial Electronics PCB Assembly Capabilities

Our 20,000-square-foot air-conditioned static-free environment is equipped with advanced machines and production lines to handle high-complexity projects. When this is combined with the expertise of our design/engineering team, you can rest assured of high-quality PCB manufacturing services with core capabilities in the following areas:

- BGA and Micro BGA Placement

- Cable and Wire Harness Assembly

- PCB Design and Reverse Engineering

- Box Build Assembly

- Conformal Coating

- IC Programming

- In-Circuit and Functional Testing

- X-Ray Inspection

- Automated Optical Inspection

- BGA Rework

- Complex RoHS & non-RoHS PCAs up to 18”x20”.

- PTH, SMT & Mixed Technology Assembly

- No Clean Flux Process

- Conformal Coating and Potting Compliant with IPC-CC-830B.

- Cable and Harness Assembly

- Complete Mechanical Assembly

- Fixture and Fixtureless in Circuit and Functional Testing

- Repair/Rework, Including BGA and QFP

- Laser Alignment and Vision Systems for SMT Placement

- Auto-Calibration for SMT lines

The Next Industrial Revolution

Industrial electronics are more connected and capable, leveraging sensors, precision electro-mechanical assemblies, edge computing, and other rapidly evolving technology. Whether your product operates in a harsh environment or urban setting, you must deliver feature-rich, reliable products on short product cycles. To get your industry-leading products to market quickly, you need an experienced engineering and advanced manufacturing partner like Anpllopcb.

Types of Printed Circuit Boards We Offer

Here are the types of PCBs we offer at Anpllopcb:

- Flexible circuit boards: Also known as flex circuits, they are made from flexible materials such as plastic, which can bend. This makes the mounting of components easy. Also, it helps reduce the complexity of the design by reducing the need for excess wiring and connectors.

- Rigid-flex circuit boards: These are a combination of rigid and flexible components. They comprise several layers of flexible circuit substrates pasted on one or two rigid circuit boards.

- Ceramic boards: With most electronic devices becoming miniature in size, there has been a need to create small and flexible PCBs. Ceramic boards serve this purpose. There are several benefits of using ceramic PCBs, such as reduced heat dissipation, and they overcome the challenges in traditional PCBs.

- RF and microwave circuit boards: Radio frequency circuit boards can operate above 100 MHz. Those operating above 2 GHz are classified as microwave circuit boards. So, the basic difference between RF and microwave PCBs is in the operational frequency range. These are used in communication equipment to transmit and receive signals. Mobile phones and radar systems are common application areas.

We Want To Work With You!

Get an Instant Quote to Compare Price & Turn Times Side-by-Side.We make it a point to make sure that what we deliver is exactly what you want.