PCB manufacturing includes various processes for producing different types of circuit boards. One of the popular circuit board options offered by most PCB suppliers is the multilayer PCB. the entire manufacturing and assembly process for these PCB types is very interesting. Customers can even learn more about how to reduce costs by learning more about multilayer PCB assembly. This article provides detailed information.

- Multilayer PCB manufacturing process

- Major factors determining the cost of multilayer PCB assembly

- Manufacturing Considerations for Multilayer PCBs

- PCBA Professionals

Multilayer PCB manufacturing process

The method of manufacturing multilayer circuit boards is fairly simple. However, it does require engineers to pay attention to detail. The following are brief steps of the manufacturing process.

1. Front-end tool data preparation: The designer uses a computer-aided design (CAD) system to prepare the PCB layout and create the Gerber file.

2. Photo plotter is used to create an image of the PCB. This image contains the information that the machine uses to print the inner layers of the PCB from the glass fiber core.

3. Etch the inner layer using an alkaline solution and remove excess copper from the PCB image. 4.

4. Holes are punched to help align the outer and inner layers. 5.

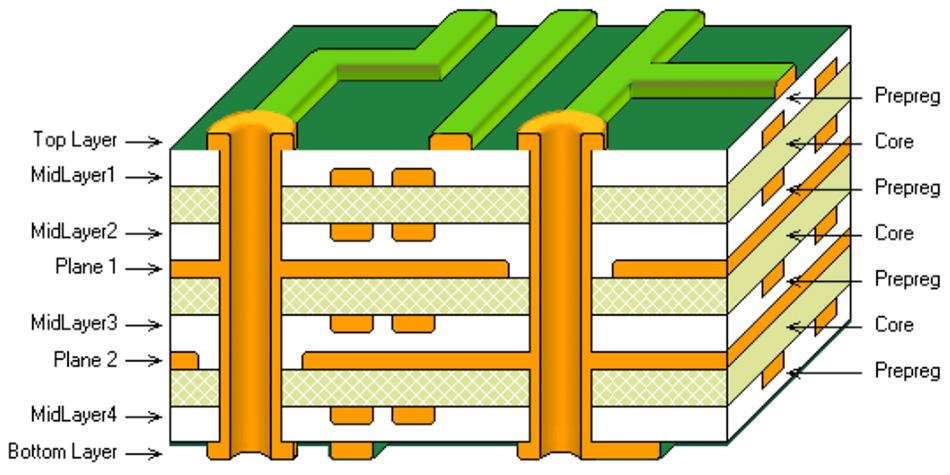

5. All layers are bonded together and holes are drilled in the PCB to connect the copper layers. Blind and buried holes are created when the PCB design does not connect all the inner layers.

6. Drilled holes are covered with a thin layer of liquid copper and then plated.

7. Etch the outer layer to remove any residual copper. A layer of tin is applied to the top of the liquid copper layer to provide protection.

8. Solder resist layers are printed on both sides of the board to protect the copper surface.

9. The PCB assembly is then soldered to the board.

10. The boards are shaped and cut to customer requirements.

11. The board is checked and all errors are corrected before it is sent out.

Major factors determining the cost of multilayer PCB assembly

Several industries that use complex PCBs in increasingly miniaturized products have made extensive use of multilayer PCBs. however, many factors determine the cost of multilayer PCBs. Quick overview.

Material Selection

The materials used to manufacture a circuit board have a significant impact on its cost. When selecting materials for your PCBs, you need to consider several factors, such as

Do you need the board to withstand high operating temperatures? For boards that need to operate at high operating temperatures, you need boards made of copper-clad laminates (CCL) and PP materials with high glass transition temperatures. With low Tg materials, you run the risk of resin delamination, which can break electrical connections at high temperatures.

Another major factor to keep in mind is signal performance. Therefore, the choice of material depends on whether the material will promote an uninterrupted electrical signal.

The mechanical properties of the board are also critical to ensure that the board can withstand any foreseeable mechanical stresses and strains.

Circuit Board Size

The size of a PCB is also a determining factor in its cost. Substrate materials are usually billed by size, so large PCBs will need to be paid for. However, this does not mean that the standard rule that the smaller the PCB the cheaper it is will be used. This is because the wiring time and labor involved in small PCBs can be very time-consuming. The size of the PCB and the processing time involved therefore affects the cost.

Number of PCB layers

Another major determinant of cost is of course the number of layers. For example, if you are talking about a double-sided PCB, you are talking about no copper foil lamination and no need to add layers that need to be processed. Therefore, as a rule of thumb, the more layers, the more resources and time are required for the manufacturing process, and therefore the higher the cost.

Surface finish

The choice of surface finish can also affect the cost of multilayer PCB manufacturing. Certain finishes are known for their quality and longer shelf life and obviously, add to the cost. For example, if you choose the HASL finish, the cost is low. In contrast, ENIG coatings cost slightly more. In HDI PCB designs, it may often be necessary to use multiple surface finishes, which in turn may impact the cost.

Hole type and density

The price of multilayer PCB manufacturing depends on the following factors.

(1) Hole size

(2) Density

(3) Hole type

For hole size, the standard aspect ratio followed is 8:1. If the hole size changes, it means that custom tooling is required to meet your custom requirements and additional costs will be incurred. Similarly, while hole densities below 120Kpcs / sqm are normal, any such variation will again increase costs. Similarly, standard through-hole costs are standard, however, if the board requires any blind and buried holes, costs tend to rise.

Alignment width and spacing

To avoid overheating, sufficient alignment width is required on multilayer boards. Therefore, engineers can consider whether they need to increase the alignment width or add additional solder, both of which can increase the cost of materials and related work.

PCB Thickness

Thicker materials typically cost more to produce, laminate, and process into PCBs. If the design is complex, the cost increases. Another aspect that affects the price is the aspect ratio.

Requirements for any special processes

If any unique design elements require any special processes, then this will have an impact on the cost. Some of the processes that can affect cost include impedance control, carbon inks, blind vias, edge plating, depth control, halogen-free materials, etc.

The above factors can affect the cost of multilayer PCBs, so be careful when making any budgetary decisions for multilayer PCB assembly.

Manufacturing Considerations for Multilayer PCBs

Many times, customers require unconventional designs or other specifications for the final PCB. While this is not impossible, it can result in higher prices, more manufacturing time, and slower lead times. Therefore, the following points need to be considered when multilayer PCBs.

1. The correct material should be selected for the front side to support the weight of the multilayer.

2. The layers and boards should be arranged in the order provided in the drawing.

3. Larger geometry will result in a higher price for the total number of PCBs.

4. The copper used for the inner layer should be 10 or 20 miles away from the outer edge of the board.

5. Reverse pads should be used to ensure that the through-hole passes through the inner layer.

6. If there are no holes or through-holes connected to any of the inner layers through the barrel, make sure that the gap between the holes and the barrel is approximately 15 or 20 mils.

7. All layers should be aligned with the specific holes drilled in the board. In addition, alignment should be retained even if the PCB is subjected to heat or pressure.

PCBA Professionals

Anpllopcb is a PCB solution provider. We can meet your PCB requirements from part procurement to electronic assembly. We will help you every step of the way and provide you with comprehensive expertise and quality assurance.

When you choose us as your partner PCBA company, you choose to work with a partner that offers the best service. Our PCB assembly services meet the highest quality standards and are compliant with IPC Class 3, RoHS, and ISO 9001:2008 certification standards. In addition, we can handle any type of PCB, whether it’s double-sided or single-sided, SMT, through-hole, or mixed assembly projects. Anything you want to do, we can do it!

From the start of the project to the finish line, we will stay in touch with you and keep you informed of the entire process from manufacturing to assembly. This can help you save money and stress with lower PCB costs, shorter wait times, and higher-quality products. We want to save you time and effort so you can focus on your PCB design – and not worry about the details of the manufacturing process.