- BOM Preparation

- Design for manufacturability of PCB pads

- Solder Paste Printing

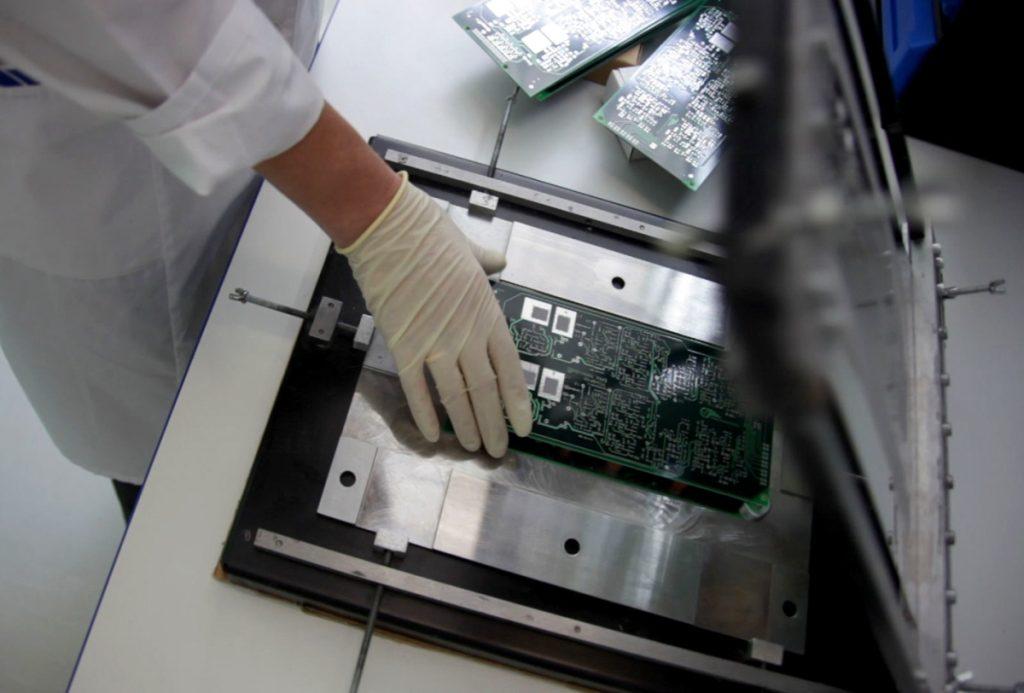

- Component Mounting

- Reflow Soldering

- PCB manufacturing for Anpllopcb

With the development of the economy and science and technology, people put forward higher and higher requirements for electronic products with multi-function, miniaturization, high density, high performance, and high quality. Therefore, for the PCBA processing industry, high soldering quality is the life insurance of electronic products.

SMT soldering is one of the important parts of the assembly process of electronic products; if there is no corresponding SMT welding process quality assurance, then any well-designed electronic equipment is difficult to achieve the design goals. Therefore, the welding in the welding to be a severe view of the solder joints to prevent the presentation of unqualified solder joints quality problems leads to the complete electronic product failure. The following is to introduce you to various electronic SMT welding shortcomings for the problem.

First, after the SMT welding operation, check the welding quality work to ensure the product has a reliable function. The soldering inspection is generally an appearance inspection, not only to check the solder joints but also to check the condition around the solder joints, such as the problems derived from the soldering. The wiring of the wiring post is checked from the condition of the welding, check the insulation of the wire is used to see if there is damage to the outer skin; the wiring post has no scars; hook welding of the wire hook hanging the degree of bending and tightness of the situation, the parts have no dirty spots, Etc. The electrical function of the electronic components found in the function of damage, there are many because of poor welding caused.

In the end, the welding of electronic products is mainly used in the electrical connection. If a product with a flawed electrical connection presents a problem, it must be repaired to eliminate its shortcomings.

However, soldering defects usually occur in actual manufacturing, especially in the reflow stage. Soldering problems at this stage are not entirely caused by reflow technology because SMT soldering quality is closely related to PCB pad manufacturability, stencil design, component and PCB pad solderability, manufacturing equipment status, and solder quality. The paste and technical parameters of each link and the functional skills of each worker.

Problems can occur in each link, affecting the quality of SMT soldering. This article will discuss and analyze elements that may affect SMT solder quality to avoid similar problems in actual manufacturing.

BOM Preparation

As one of the most important composite materials in SMT, the quality and performance of the BOM are directly related to the quality of reflow soldering. Specifically, the following aspects must be considered.

1. The component packaging must meet the automatic mounting requirements of the mounting protocol.

2. The part graphics must meet the requirements of automatic SMT as it must have a standard shape with high dimensional accuracy.

3. The soldering quality of the component’s solderable ends and PCB pads should meet the requirements of reflow soldering. The solderable ends of the component and pads must not be contaminated or oxidized. If the solderable ends of components and PCB pads suffer from oxidation, contamination, or moisture, several solder defects may occur, such as poor wetting, pseudo-soldering, solder beads, or cavities. This is especially true for humidity sensors and PCB management. Humidity sensors must be stored in a dry box after vacuum packing, and it is necessary to bake them before the next manufacturing.

Design for manufacturability of PCB pads

The level of SMT depends on the quality of the PCB design and is the first element that affects the quality of the surface mount. Based on statistics from HP, 70% to 80% of manufacturing defects from derived PCB design issues in substrate material selection, conversion component layout, pad, and thermal pad design, solder mask design, component package type, component approach, transmissive boundaries, via positioning, optical positioning points, EMC (electromagnetic compatibility), Etc.

For PCBs with correct pad design, even if a small skew occurs during surface mounting, it can be corrected under the surface tension of molten tin, which is called auto-positioning or self-correcting effect. However, if the PCB pads are not designed correctly, even if the mounting position is very accurate, soldering defects will still be encountered, such as component position offset and riser. Therefore, the following aspects must be carefully considered in SMT pad design.

1, the symmetry of the pads. In order to avoid position shift and standing monument problems after reflow soldering, for 0805 and below chip components, the pads at both ends should be symmetrical in terms of pad size and the ability to absorb and dissipate heat in order to maintain a balance of melting surface tension. Solder. If one end is on a large copper foil, it is recommended to use a single wire connection to connect the pads on the large copper foil.

2. Space between pads. Ensuring the proper lap size between the end of the component or the pins and the pads will often lead to soldering defects when the space between the pads is too large or too small.

3, the remaining dimensions of the pads must ensure the end of the component or the lap between the pins and the pads after the lap of the curved moon-shaped solder joint.

4, The width of the pad should be compatible with the width of the end of the component or the pin.

5、Do not place through holes in the pads. Otherwise, melted tin may flow along the through-hole during reflow soldering, resulting in pseudo-soldering and insufficient tin. It may flow to the other side of the board, thus causing a short circuit.

Solder Paste Printing

The main purpose of solder paste printing technology is to solve the problem of incompatibility with the amount of solder paste printed (the amount of fill and transfer of solder paste). According to professional statistics, 60% of reworked PCBs are caused by poor solder paste printing when the PCB is designed correctly. In solder paste printing, three important ” S ” must be remembered: solder paste, stencil, and squeegee. If you choose the right one, you can get excellent printing results.

1. Quality of solder paste

As a necessary material for reflow soldering, solder paste is a kind of alloy powder, and flux (rosin, thinner, stabilizer, Etc.) is uniformly mixed into the solder paste, where the alloy powder is the key element that constitutes the solder joint. Flux is the key material to eliminate surface oxidation, improve wettability and ensure the quality of the solder paste. In terms of quality, 80% to 90% of the solder paste belongs to the metal alloy, while 50% of its volume. Solder paste quality assurance comes from two main sources: storage and application. Solder paste is usually stored between 0 and 10°C or according to the manufacturer’s requirements. For its application, the SMT shop must have a temperature of 25°C ± 3°C and a humidity of 50% ± 10%. Also, it must have a recovery time of 4 hours or more and be well stirred before use to give excellent printability and release deformation of its viscosity. The solder paste cover must be placed correctly after application, and the board coated with solder paste must be reflow soldered within two hours.

2、Stencil design

The key function of the stencil is to apply solder paste evenly on the PCB pads. Stencil is essential in printing technology, and their quality directly affects the quality of solder paste printing. So far, there are three methods of manufacturing stencils: chemical etching, laser cutting, and electroplating. It will not be possible to ensure the mold design until the following aspects are fully considered and properly handled.

3、Thickness of the steel plate

In order to ensure the quantity of solder paste and welding quality, the surface of the stencil must be smooth and flat. The thickness of the steel plate should be determined by the component with the smallest spacing between the pins.

4、Aperture design

The opening is a trapezoidal truncated hole with a flared opening. They have smooth walls without burrs. Width-thickness ratio = width of the hole/thickness of the stencil (for small pitch QFP, IC); area ratio = basic area of the hole/wall area (for 0201, BGA, CSP parts). c. Anti-solder ball processing. Anti-solder ball processing implemented on stencil holes 0603 or above CHIP components can effectively avoid solder balls after reflow. It is recommended that a grid division be used to stop excessive generation for components with too large pads. d. Marking. At least 3 MARK points should be generated on the B side of the stencil, and the stencil should be compatible with the MARK on the PCB. To increase printing accuracy, there should be a pair of MARK points with the longest diagonal distance. e. Printing direction. Printing direction is also a key control point. In determining the printing direction, components with a small spacing between each other should not be too close to the guide. Otherwise, too much tin may lead to bridging.

5、Squeegee

Squeegee, based on its different hardness material and shape, to some extent, will affect the quality of printing. Usually, steel squeegees with nickel plating are used, and 60° squeegees are usually used. If there is a through-hole component, it is recommended to use a 45° squeegee to increase the tin content on the through-hole component.

6、Printing parameters

Printing parameters mainly include squeegee speed, pressure, low release speed, stencil cleaning pattern, and frequency. There is indeed a limiting relationship between the angle of the squeegee and the stencil and the viscosity of the solder paste, so only correct control of these parameters can ensure the printing quality of the solder paste. In general, low squeegee speeds result in relatively high print quality, and the shape of the solder paste may be blurred. In addition, very low speeds even reduce manufacturing efficiency. Conversely, high squeegee speeds may lead to the underfilling of the solder paste in the mesh. Too high squeegee pressure may result in insufficient tin, which increases wear between the squeegee and the stencil, while very low pressure may result in incomplete solder paste printing. Therefore, the speed should be increased as much as possible when rolling the solder paste normally. In addition, squeegee pressure should be adjusted to obtain high print quality. Extremely high downward release speeds may cause solder paste to freeze or form poorly, while low release speeds can affect manufacturing efficiency. Inappropriate stencil cleaning methods and frequency can result in incomplete cleaning, continuous tin electrodeposition, or insufficient tin in the stencil holes resulting in narrow space products. Extremely high downward release rates can lead to the icing of solder paste or the formation of undesirable phenomena, while low release rates can affect manufacturing efficiency. Improper stencil cleaning methods and frequency will result in incomplete cleaning, continuous tin electrodeposition, or insufficient tin in the stencil aperture resulting in narrow space products. Extremely high downward release rates may result in the icing of solder paste or the formation of undesirable phenomena, while low release rates will affect manufacturing efficiency. Unsuitable stencil cleaning methods and frequency will lead to incomplete stencil cleaning, continuous tin electrodeposition, or insufficient tin in the stencil hole will lead to narrow space products.

7、Equipment accuracy

High-density, small-space printing products, printing accuracy, and repeat printing accuracy will affect the stability of solder paste printing.

8、PCB support

PCB support is an important adjustment to the content of solder paste printing. If the PCB lacks effective or improper support, thick or uneven solder paste should be used. PCB support should be arranged flat and uniform to ensure tightness between the stencil and the PCB.

Component Mounting

The quality of component mounting depends on three elements: proper component selection, accurate placement, and proper mounting pressure. Correct component selection refers to the fact that the components must be compatible with the requirements of the BOM. Correct placement means that the coordinates must be installed correctly and that the accuracy of the mounting protocol must ensure mounting stability and proper installation of the component on the pad. Also, attention must be paid to the mounting angle to ensure the correct orientation of the component. The proper mounting pressure is the pressed thickness of the component and must not be too small or too large. The mounting pressure can be determined by setting the PCB thickness, the component package thickness, the bonder pressure of the nozzle, and adjusting the Z axis of the bonder.

Reflow Soldering

The quality of the solder joint depends on the correct setting of the reflow temperature profile. A good reflow profile requires that all mounted components on the PCB receive excellent soldering and that the soldered joints should combine excellent appearance with high quality. If the temperature rises too quickly, on the one hand, the components and the PCB will be so hot that the components will be easily damaged, and the PCB will be deformed. On the other hand, the solvent in the solder paste evaporates too quickly, and the metal compound spills out as a tinned ball. The peak temperature is usually set to 30°C to 40°C above the melting point of the heat-resistant solder components, or component plastics can be damaged waste. If the temperature is too high and the reflow time is damaged.

Conversely, incomplete melting of the solder paste results in reliable solder joints. To improve the solder quality and stop the component’s oxidation, nitrogen reflow can be applied. The reflow profile is usually set according to the following.

a. It can be set according to the recommended temperature profile of the solder paste. The composition of the solder paste determines its activation temperature and melting point.

b. Depending on the thermal performance parameters of heat-resistant and valuable components, the maximum soldering temperature must be considered for some special components.

c. The setting should be based on the PCB substrate’s material, size, thickness, and weight.

d. The settings should be based on the structure of the reflow oven and the length of the temperature zone and different reflow ovens should have different settings.

There are many factors that affect the quality of SMT soldering, including the solderability of components, PCB quality, PCB pad design, solder paste quality, PCB manufacturing quality, the condition of SMT manufacturing equipment, the technical parameters of each SMT link, and the operating skills of each worker. Among these elements, the quality of components, PCB and solder paste, and PCB design are critical to reflow quality assurance because solder defects caused by these elements are difficult or impossible to resolve with technical solutions. Therefore, the primary requirement for improving excellent solder quality lies in good control of material quality and excellent PCB pad design. In addition, the technical parameters of the various solder paste printing process stages.

PCB manufacturing for Anpllopcb

In today’s high-tech world, printed circuit boards are becoming more and more complex as technicians find ways to load more data and energy onto smaller and smaller chips. As computer equipment and electronic devices become smaller, the PCBs that power and connect them to the radio network will also become smaller. For PCB manufacturers, this means that the production of printed circuit boards will require advanced levels of engineering.

To increase the efficiency of your PCBs to current standards, you must have properly specified bare PCBs to perform each step in the assembly process more efficiently. At Anpllopcb, we use the latest technology in our facilities to complete each bare PCB order to customer specifications. For more information on PCB manufacturing, please contact Anpllopcb.

Do you have questions about our services or your project? Contact us today to speak with Anpllopcb’s award-winning support team!