- 1. What is sunken gold?

- 2. Why do we need to sink gold?

- 3. What are the benefits of this surface treatment of sunken gold?

- 4. What benefits does the printed wiring board use the sunken gold process?

- 5. Sinker gold and gold finger

- 6. Sink gold process flow

- Contact us

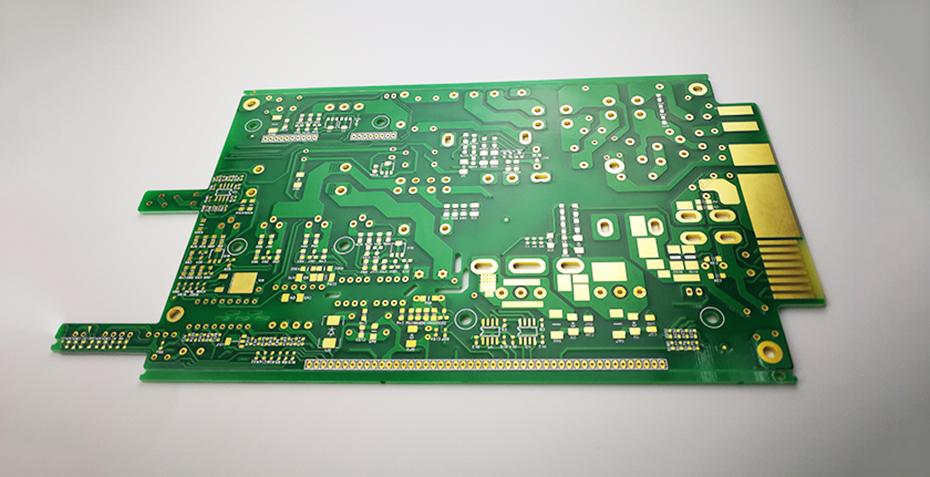

In the printed circuit board surface treatment, there is a very common use of the process called sink gold. The immersion gold process makes the PCB printed circuit surface deposition of long-lasting colour, good brightness, flat plating, and good solderability of nickel-gold plating. Plus, the sink gold PCB shows a golden colour, this colour is more golden than the colour of gold plating because the sink gold more bright and good-looking, for customers presented customers is a piece of high quality that looks very comfortable feeling; customers will also be more satisfied with our products.

1. What is sunken gold?

In simple terms, sink gold uses a chemical deposition method through the chemical redox reaction on the surface of the printed circuit board to produce a layer of metal coating.

2. Why do we need to sink gold?

Printed circuit board copper is mainly purple copper; copper solder joints in the air easily oxidize, which will cause electrical conductivity to eat poor tin or poor contact, reducing the board’s performance.

Then it would help if you surfaced treatment of copper solder joints; sink gold is gold plating on the top; gold can effectively block copper metal and air to prevent oxidation, so sink gold is a surface anti-oxidation treatment, is through a chemical reaction on the surface of copper covered with a layer of gold, also called gold.

3. What are the benefits of this surface treatment of sunken gold?

The benefits of the sink gold process are that the PCB printed lines on the surface deposited colour is very stable, brightness is very good, the plating is very flat, and solderability.

Sink gold has a general gold thickness of 1-3Uinch, so sink gold this surface treatment way to do out of the gold thickness is generally thicker. Sink gold this surface treatment is commonly used in the keypad, gold finger board and other printed circuit boards because of the strong conductivity of gold, good oxidation resistance, and long service life.

4. What benefits does the printed wiring board use the sunken gold process?

1) The colour of the sunken gold board is bright, good colour and has a good appearance.

2) The crystal structure formed by the sunken gold is easier to solder than other surface treatments, which can have better performance and ensure quality.

3) The sink gold plate only in the pad with nickel gold will not impact the signal because the skin effect in transmitting the signal is in the copper layer.

4)The metal property of gold is more stable, the crystal structure is dense, and it is not easy to occur oxidation reaction.

5)Because the sink gold board only pads with nickel gold, the line of solder resistance and a copper layer of the combination is more solid but does not easily cause a micro-short circuit.

6)The project will not impact the pitch when making compensation.

7) The stress of the sinker board is easier to control.

5. Sinker gold and gold finger

The gold finger is called brass contact, which can also be said to be the conductor. Because gold is extremely resistant to oxidation and conduction, the parts on the memory stick connected to the memory slots are plated with gold. All signals are transmitted through the gold fingers. The gold finger is composed of numerous yellow conductive contacts with a gold-plated surface, and the conductive contacts are arranged like fingers, hence the name. In layperson’s terms, gold fingers are the connection between the memory stick and the memory slot, and all signals are transmitted through the gold fingers. Gold fingers are made up of numerous gold-coloured conductive contacts and are a layer of gold overlaid on a copper-clad board through a special process. So, the simple distinction is that sinking gold is a surface treatment process of the printed circuit board, while the gold finger is the printed circuit board with a signal connection and conductive components. The gold finger may not really surface for gold in the market. Because of the high price of gold, more memory uses tin plating instead. From the 1990s, tin materials began to popularize; the current motherboard, memory and, graphics cards and other equipment “gold finger” is almost all used in the tin material, only some high-performance server/workstation accessories contact points will continue to use the practice of gold plating, the price is naturally not expensive.

6. Sink gold process flow

(1) process introduction

The purpose of the sink gold process is to manufacture PCB when the printed circuit surface deposition of long-lasting colour, good brightness, flat plating, and good solderability of nickel-gold plating.

It can be divided into four stages: pretreatment (oil removal, micro-etching, activation, post-dipping), nickel sink, gold sink, and post-treatment (waste gold wash, DI wash, drying).

(2) Pretreatment

Sink gold pretreatment generally has the following steps: oil removal (30% AD-482), micro-etching (60g/InaPS, 2% H2SO4), activation (10% Act-354-2), after the dip (1% H2S04). To remove the oxide on the copper surface and sink palladium on the copper surface as a nickel activation centre. Poor treatment in one of the steps will affect the subsequent nickel and gold deposition and lead to batch scrap. The various chemicals must be analyzed and refilled during the production process to stay within the required limits. More importantly, for example, the micro-etching rate should be controlled at “25U-40U”, the copper content of the activation portion is greater than 800PPM, the cleaning and maintenance of the potion cylinder have a greater impact on the quality of the PCB, in addition to the oil cylinder, micro-etching cylinder, after the dip cylinder should be changed every week, the water washing cylinder should also be cleaned every week. Cleaning.

(3) Sink nickel

The main components of the nickel sink solution are Ni2+ (5.1-5.8g/1) and reducing agent sodium hypophosphite (25-30g/1) and stabilizer, due to the chemical nickel composition of the solution range is relatively strict, in the production process must be analyzed and tested twice a shift, and according to the bare copper area of the production board or experience to add Ni2 reducing agent, replenish the material, should follow the principle of a small amount, scattering multiple replenishment, in order to PH value, the temperature of the plating solution has a greater impact on the nickel thickness, the temperature of the nickel potion is controlled at 85℃-90℃, PH at 5.3-5.7, the nickel cylinder is not produced, the temperature of the nickel cylinder should be reduced to about 70℃ to slow down the aging of the plating solution, the chemical nickel plating solution is more sensitive to impurities, many chemical components are harmful to the chemical nickel, which can be divided into the following categories.

Hg.Ti.Bi (heavy metals with low melting point), organic impurities including S2, nitric acid and anionic wetting agent. All these substances will reduce the activity, lowering the speed of chemical plating and leakage. When severe punishment is, it will lead to the complete stop of the chemical nickel plating process.

Organic impurities: In addition to the organic stabilizers mentioned above, there are plastic agents and impurities from equipment and solder. Although some impurities can be removed by continuous plating, they cannot be completely removed.

Unstabilizers: including Pd and a small amount of copper, these two components in the chemical nickel instability, making the layer rough, and too much plating on the tank wall and the heater.

Solid impurities: including calcium sulfate or phosphate and other insoluble substances, sink into or are carried into the solution. Filtration can remove solid particles.

In short, in the production process, take effective measures to reduce such impurities mixed into the plating solution.

(4) Immersion gold

The sink gold process is a kind of immersion gold process; sink gold cylinder main component; Au (1.5-3.5g/l), binding agent for (Ec0.06-0.16mol/L), can replace the pure gold plating monster on the nickel-phosphorus alloy layer, making the plating layer smooth, crystalline and meticulous, the plating solution PH value is generally between 4-5, control the temperature of 85 ℃ -90 ℃.

(5) Post-treatment

Sink gold post-treatment is also an important link to the printed circuit board, generally including waste gold washing, DI water washing, drying and other steps; if possible, you can use the horizontal washboard accumulation of sink gold board for further washing and drying. The horizontal surface washing machine can be washed according to the drug water (sulfuric acid 10%, hydrogen peroxide 30g / L), high-pressure DI water washing (30 ~ 50PSI), DI water washing, blowing dry, drying sequence set process to thoroughly remove the printed wiring board hole and the surface of the drug water and water stains, and get a uniform coating, good brightness of the sink gold plate.

(6) Production process control

In the sink nickel, gold production process often appears problems; the imbalance in the composition of the plating solution, additive quality and plating solution magazine content exceeds the standard. To prevent and improve this problem, process control plays a big role; now, the production process should pay attention to the following factors: chemical nickel gold process flow and the surface of the plating solution.

1) chemical nickel-gold process flows because there are small holes; water washing between each step is necessary and should pay special attention.

(2), micro-etching agent and palladium activator between micro-etching, copper is easy to fade, and in serious cases make, the palladium layer is not uniform, which leads to the failure of the nickel layer if the printed circuit board water wash is not good, from the micro-etching oxidizer will prevent the deposition of palladium, the result affects the effect of sinking gold, thus affecting the quality of the board.

(3) palladium activator and chemical nickel between palladium in the chemical nickel process is the most dangerous impurity; a very small amount of palladium will make the natural decomposition of the tank solution. As much as the concentration of palladium is very low, it should be well-washed before entering the chemical plating tank. It is recommended to use two washes with air agitation.

(4) between chemical nickel and immersion gold In between these two steps, the transfer time is easy to make the nickel layer passivation, resulting in uneven immersion gold and poor bonding. This is easy to cause dumping gold now tin.

(5) after the immersion of gold in order to maintain the solderability and ductility, gold plating after full water wash (a water wash with distilled water), and completely dry, especially completely dry inside the hole.

6)Sink nickel cylinder PH, temperature The sink nickel cylinder should be raised PH, adjusted with less than 50% ammonia, and lower PH with 10% V/V sulfuric acid. All additions should be injected slowly with continuous stirring. pH measurement should be done with full stirring to ensure a balanced plating solution concentration. The higher the temperature, the faster the plating rate. A low temperature slows down the needle’s appearance when plating thick layers.

Contact us

Anpllopcb providing some of the most innovative printed circuit board technologies and highest quality standards in the industry. You can count on us to meet your needs, from the simplest boards to the most complex designs for small quantity and large scale production.