- PCB technology applied to the LED lamp introduction

- What types of LED PCBs are available?

- What is the flow of LED PCB design?

- How to prevent defects in the LED PCB?

- What are the most common applications of PCB LEDs in the lighting industry?

- LED PCB development in various countries

People have been increasingly concerned about low carbon, energy saving, and environmental protection in recent years. The use of LED lighting is in line with the development trend and trend of energy saving.LED is a light-emitting diode. It is not an energy-saving or fluorescent tube, but the brightness is 5 to 6 times that of ordinary lamps. Because of this, LED lighting is becoming a major trend in energy-saving lighting.

Since September 1, 2009, the EU regulations that all supermarkets shall not sell incandescent bulbs nor high-pressure fluorescent lamps; only LED lamps can be sold. Compared with incandescent lamps, LED lighting’s energy-saving effect is very obvious.

PCB technology applied to the LED lamp introduction

After the gradual improvement of traditional energy sources, the world has taken a step forward. Among them is the light radiation in semiconductors with direct energy. In all energy applications, the use of LED lamps has increased. One of the main challenges facing the LED lighting and emergency lighting industry is the extent of thermal management, which can balance the thermal output of high-energy applications well. In addition, new trends in miniaturization and nano-concepts in the global market have increased the need for custom PCB manufacturing and PCB prototyping, which depends on the use and usefulness of high-performance LED lights.

PCB enhancement is becoming a solid electronic processing program for numerous OEMs, EMs, and other LED-printed circuit board manufacturing units for LED lighting. It is used to adapt its products through high-end customization. It has universal applications such as lighting systems for homes, businesses, aerospace, city street lighting, projection systems, hotels, infrared heating, industrial use, automotive, bicycle lighting, medical procedures, hotels, wholesale and other markets. The biggest challenge for LED light manufacturers is integrating the right printed circuit boards into their products.

Certain aspects of design thinking are critical to obtaining accurate and optimal electronic processing plans. Proven LED printed circuit board floor plans. This includes heat, size of components, where energy loss should dissipate, proper location of heat sources, balancing temperatures, cooling systems, and proper heat sinks. In order to provide a complete electronic handling solution for the system behavior of LED lamps, the printed circuit boards are made of state-of-the-art technology, including FR4 epoxy and fiberglass PCBs, which allow heat dissipation on large surfaces and improve heat dissipation. FR4 PCBs are equipped with an array of thermal vias, where PTH (plated through-hole) technology is used in conjunction with the configuration of the thermal vias to vertically enhance thermal resistance, using “Iceberg Technology” thick copper plates for high-power LEDs and effective heat dissipation. The FR4 technology used in the PCB requires proper heat dissipation and heat dissipation, IMS (Insulated Metal Substrate) for higher thermal conductivity, and thick film or thin film technology done in the PCB assembly to meet the requirements of LED lighting.

These technologies reshape LED lights into a variety of products, including LED equipment apparel, vehicle risk lights, custom concert lights, snowflake lights, wall lights, stage lights, exhibition lights, DC security lights, handrail lights, spotlights, floor lights for swimming pools and dance floors, exit lights, and cabin lights, mainly used at entrances to hotels and exhibition centers. In addition, LED lamps are used in aircraft and ship lighting systems. This indicates that flexible polyimide substrates are increasingly used to control lighting output at low manufacturing and equipment costs. Cold LED lamps in cameras and fluorescent microscopes. Today, complexity is the competing theme for connecting LEDs to sensors and dimmers. It is also fierce competition for quality, quantity, and durability in the global LED market, aiming to reduce the number of salvage replacement operations.

This puts fashion and technology on the same level. With this, the upcoming innovation is using smart LED bulbs and fiber optics in jackets, clothes, dresses, shoes, Etc. In addition, R&D can integrate Wifi control, DMS control, software, music system, and SD card system having LED lights.

What types of LED PCBs are available?

There are different types of LED PCBs. The types of LED PCBs vary depending on manufacturing specifications, data type, and usage. The following are the most popular types of LED PCB:

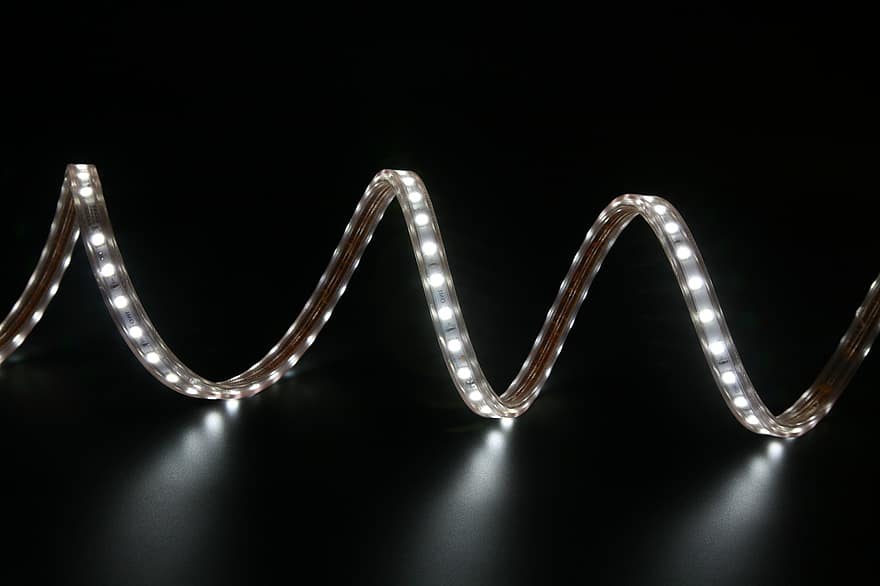

LED Flexible PCB

The name is obvious. It consists of data that can be twisted and bent in different directions. It includes multi-layer, double-layer, and single-layer formats. The cost of printing circuits on flexible materials is high. Flexible LED PCBs have more advantages than rigid LED printed circuit boards.

Rigid PCBs

Look at the literature because it is raw and goes against sensitive integrity. This factual data is used to do just that. You can find it on your computer. It can also be used for different layers.

Multi-layer PCB

This type of LED PCB board contains more than two layers. Copper-plated holes are usually connected to all layers. It contains 4 to 50 layers of conductive material. A special type of glue connects the multiple layers, and a special insulator is used between the different layers. The insulator protects them from overheating.

What is the flow of LED PCB design?

PCB design is stopped using computer-aided design software. The exact design will depend on the application under consideration. For the PCB to support LEDs, two design aspects are important. First, LEDs require devices to be in holes in the board. You must include these holes in the design. Second, these holes must be close to the positive and negative electrodes of the LEDs.

Save the design as a Gerber file. The Gerber file should have many layers. Layer 0 should show the size of the cardboard outline. The first layer should have a copper wire pattern. The second layer should have the design of the drill holes.

Create a text file that contains information about the cardboard dimensions and layer contents. Email the Gerber and text files to the LED-printed circuit board manufacturer. Purchase LED devices with the correct specifications. Please pay special attention to the required voltage and ensure it matches the PCB power supply.

Set up the PCB. Mount the LED electrodes in the PCB and solder them to the positive and negative voltage terminals. It is important to connect the terminals correctly. Connect the power supply to the voltage rails. Turn on the power supply and set the correct voltage. The PCB should now be powered up, and the LEDs will light up.

How to prevent defects in the LED PCB?

The performance of LED PCB components may degrade gradually, and the underlying cause needs to be identified. Your custom LED PCB may be affected by slight degradation, oxidation, incorrect copper weight, condensation, and solder corrosion.

If solder paste is not applied carefully, it can cause LED PCBs to be short or open. If applied a limited number of times, solder joints are more likely to break. They may be connected left and right if applied randomly and excessively, forming a short circuit.

In this case, the LED will be burned out, and the sensitive electronic components nearby. You want to ensure that the environment does not contaminate the LED PCB. In addition, electrical tests can be used to find the location of short circuits and open circuits.

What are the most common applications of PCB LEDs in the lighting industry?

(1) Telecom industry: Telecom equipment usually uses PCBs to control its LED indicators and targets. Lightweight and durable PCBs are often more advantageous, mainly because of this industry’s density of mechanical equipment. Because aluminum-based circuit boards usually have better heat transfer characteristics than FR4 circuit boards, aluminum-based circuit boards can usually be found in telecom lighting applications.

(2) Automotive industry: PCB LED displays are very common in the automotive industry, especially for dashboard indicators, headlights, brake lights, and advanced panel displays. The industry is particularly fond of PCB LEDs because of their low cost and durability, which can increase the value and longevity of vehicles.

(3) Computer technology industry: PCB-based LEDs are becoming more common in the computer technology industry, commonly used in displays and indicators for desktop and laptop computers. Due to the heat-sensitive nature of computer technology, aluminum-based circuit boards are particularly suitable for LED lighting applications in computers.

(4) Medical industry: Lighting tools are extremely important in medical applications, especially surgical and emergency applications. Strong light helps to improve the doctor’s vision. LED is usually the preferred lighting method in these applications because of its low power and small size. PCBs are often used as the basis for these applications, especially aluminum-based printed circuit boards. Compared to other PCBs, they last longer and transfer heat better. In this way, aluminum-based printed circuit boards ensure durable medical devices that can be reused in various medical environments.

(5) Residential and storefront applications: In addition to the uses listed above, PCB LEDs are becoming increasingly popular in homes and businesses in the form of signage and displays. Smart LED lighting is a cost-effective way for homeowners to illuminate their houses efficiently, and customizable LED displays can direct businesses to stores.

LED PCB development in various countries

Currently, countries worldwide attach great importance to the development and application of LEDs. Japan’s NEC has developed and marketed a new type of LED bulb, which is similar in appearance to today’s ordinary incandescent bulbs and is rapidly gaining popularity in ordinary homes. AT&S, the world’s leading printed circuit board consumer company, is actively developing LED printed circuit boards and intends to make this LED printed circuit board a pillar product of the future. Matsushita Electric developed CEM-3 copper laminate with high heat dissipation performance for LED 2 ~ 3 as early as 2 ~ 3 years ago.

Currently, the Korean government is implementing a program to convert streetlights to LED lighting. KPCA, the Korean Electronic Circuit Industry Association, has led the global standardization of LED-printed circuit boards and established the LED Printed Circuit Board Working Group. It is working on this specification to promote the standardization of LED-printed circuit boards.

This year, the Japan Electronic Circuit Industry Association (JPCA) announced the JPCA-TMC-LED01S specification for high-brightness LED electronic circuit substrates and the JPCA-TMC-LED02T experimental method for high-brightness LED electronic circuit substrates.

LED PCB is not only metal-based (aluminum-based) copper-clad PCB; depending on the use, some use common FR-4, FR-5, CEM-3, flexible polyimide board, some use resin substrate with heat dissipation through-hole and high thermal conductivity, some use metal-based substrate, metal core substrate, ceramic substrate.

According to the characteristics of LED energy saving, it will certainly become a very important industry. LED lighting is widely used, and the market is huge, not only has a huge impact on energy saving and consumption reduction, but it also will provide a huge market for the printed circuit industry.

In the information age, information is opportunity. Can entrepreneurs in the printed circuit board industry see the business opportunities of LED? Let us get ready for the arrival of the latest LED lighting era!