- What is turnkey PCB assembly?

- Types of Turnkey PCB Assemblies

- Different stages of turnkey PCB assembly

- Advantages of turnkey PCB assembly

- Anpllo Introduces New Rapid PCB Turnkey Assembly Service for Low Volume Production in 6 Days

What is turnkey PCB assembly?

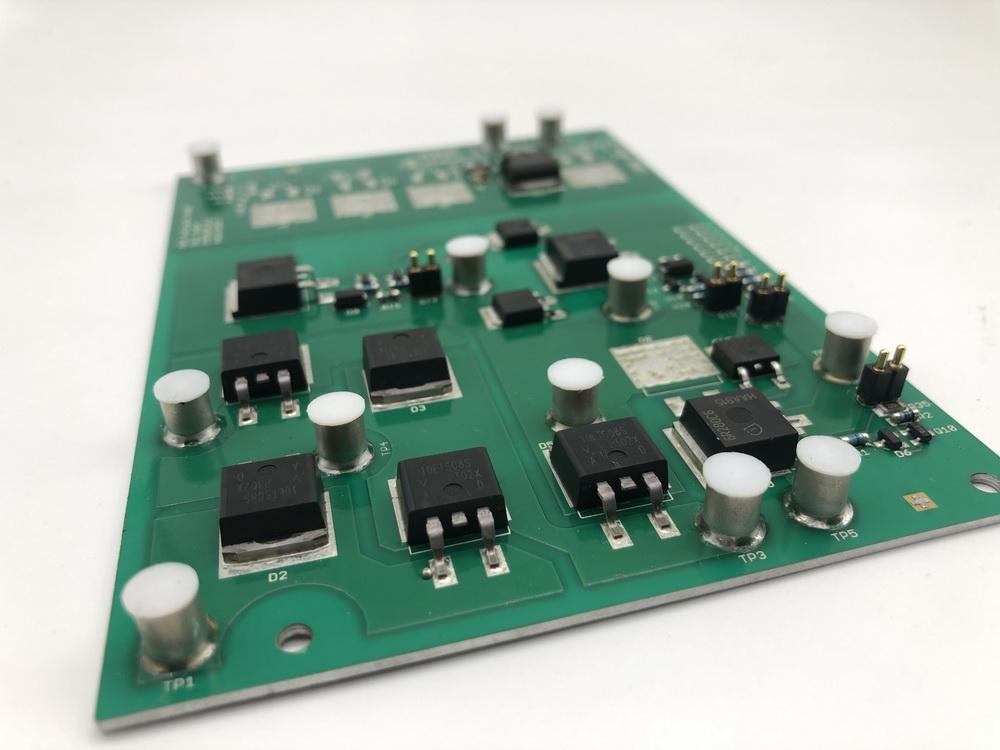

Turnkey PCB assembly means that the PCB manufacturer takes care of all aspects of your PCB project, including electronic sourcing components, printed circuit board manufacturing, PCB fabrication and assembly services, PCBA testing, final assembly, testing, and shipping, so they deliver a product that is ready for immediate use. When using a turnkey PCB assembler, you can get a PCBA with a very short turnaround time because all the processes involved are done under one roof. There are many benefits to turnkey PCB assembly, and we will discuss them in this blog.

Types of Turnkey PCB Assemblies

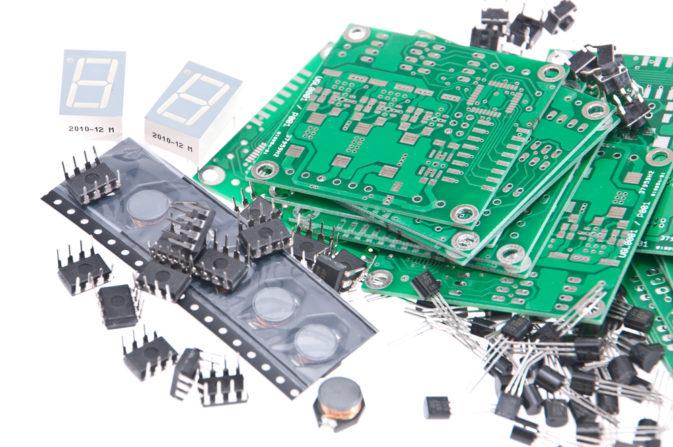

The essence of turnkey PCB assembly services gives the buyer enough time and freedom to focus on the actual PCB design. In addition, this allows the turnkey PCB assembly service provider to handle the entire PCB assembly process.

Box build assembly, also known as the mechanical system integration phase, allows the PCB manufacturer to perform other services that may be simple or complex. The process involves performing all other necessary services and the actual PCB manufacturing. In short, box assembly is the difference between PCB assembly and final product delivery.

Boxed PCB assemblies provide designers with a necessary means of inspection and testing. Designers must ensure that their PCB work is compliant with specifications and aligned with world best practices. Achieving this goal will cost them significant money to set up dedicated test facilities.

Some of the processes involved in PCB-in-a-box assemblies include, but are not limited to, the following.

(1) Help with the installation and design of all subassemblies of the assembly.

(2) Software loading.

(3) System configuration.

(4) Assisting in packaging the assembled printed circuit boards into the enclosures.

(5) Packaging and labelling of the final product.

(6) Assistance with procurement and installation of cables and harnesses.

Different stages of turnkey PCB assembly

Phase 1: Seamless prototype PCB assembly

Previously, it was challenging for PCB manufacturers to take on PCB prototypes due to the huge costs. In addition, this was a problem for designers because traditional electronics manufacturing services were designed for large orders. In addition, accepting small orders or prototype orders was expensive and wasteful of materials.

This has disappeared as software innovations allow for PCB prototyping and small business production runs. For example, designers can upload their design files and bill of materials directly and receive instant quotes. With such sophisticated software, prototype delivery can be done in a much shorter time frame.

Phase 2: PCB Manufacturing

The PCB prototyping and iterative process are followed by the PCB manufacturing phase, which is a custom PCB, and quantity affects cost. Still, now PCB assembly companies accept orders for any quantity by submitting a Gerber to provide a reasonable quote file.

In addition, PCB assembly suppliers now have pricing tools that allow customers to determine the cost per PCB manufacturing run. Designers can also track and report on the board assembly process.

Phase 3: PCB electronics assembly

A smooth PCB turnkey solution means that the printed circuit board manufacturer responsible for PCBA production can assemble the entire electronic device. Another advantage of having your PCB manufacturer build your electronic devices is the advantage of lower costs and reduced component shipping delays. It is also the most cost-effective for small businesses that want low-cost product assembly.

Phase 4: PCB inventory storage and management

After completing the PCBA placement process, the manufacturer can assist in renting space for proper maintenance and inventory before shipping to the customer. Using box-build-type services is also an advantage.

Phase 5: Customer Satisfaction

Decent turnkey printed circuit board assembly services will ensure that both designers and users are satisfied. This satisfaction comes from ensuring they see the product lifecycle’s final stage. As a result, the company saves designers the hassle of product distribution and reduces shipping.

Phase 6: System Integration

The final stage of a suitable PCB turnkey solution is system integration. This stage is essential in PCB assembly because a PCB manufacturer can only meet the customer’s needs if it knows whether an order has been placed. Therefore, a good PCB manufacturer has software that allows designers to integrate their ERP systems via their APIs, such as banking applications.

Advantages of turnkey PCB assembly

High Quality

Working with a professional turnkey PCB assembler ensures product quality, and their expertise allows you to get a high-quality product at an affordable price. For example, they have the expertise to review the quality of components during the procurement process to ensure they get the best component quality. But what if you do it yourself? You may get an unfair deal because you don’t know how to judge quality, especially if you are a one-time buyer, and those component suppliers may offer you a high price quote.

Save time: shorter lead times.

The obvious advantage of handling the entire PCB assembly through a PCB turnkey manufacturer is to save the customer team valuable time from focusing on other aspects of the business, which is where their expertise lies. As a customer, you don’t need to spend time and effort looking for cost-effective quotes for individual components, going through the hassle of sourcing them, and then putting all those quotes together. This also works well from a cost perspective, as PCB turnkey services are priced far more effectively than bundled services.

Turnkey PCB assembly services can reduce lead times compared to other PCB assembly services because all processes are done together by the same supplier. As with other PCB assembly services, you must work with partners to complete all the steps, like electronic component suppliers, PCB manufacturers, shipping companies, Etc. These processes take a long time, and you must work with different partners. These processes take a long time, especially when you have suppliers from different cities and countries. Turnkey PCB assembly services can eliminate this hassle and help avoid project delays or misunderstandings caused by miscommunication.

Proof of Concept

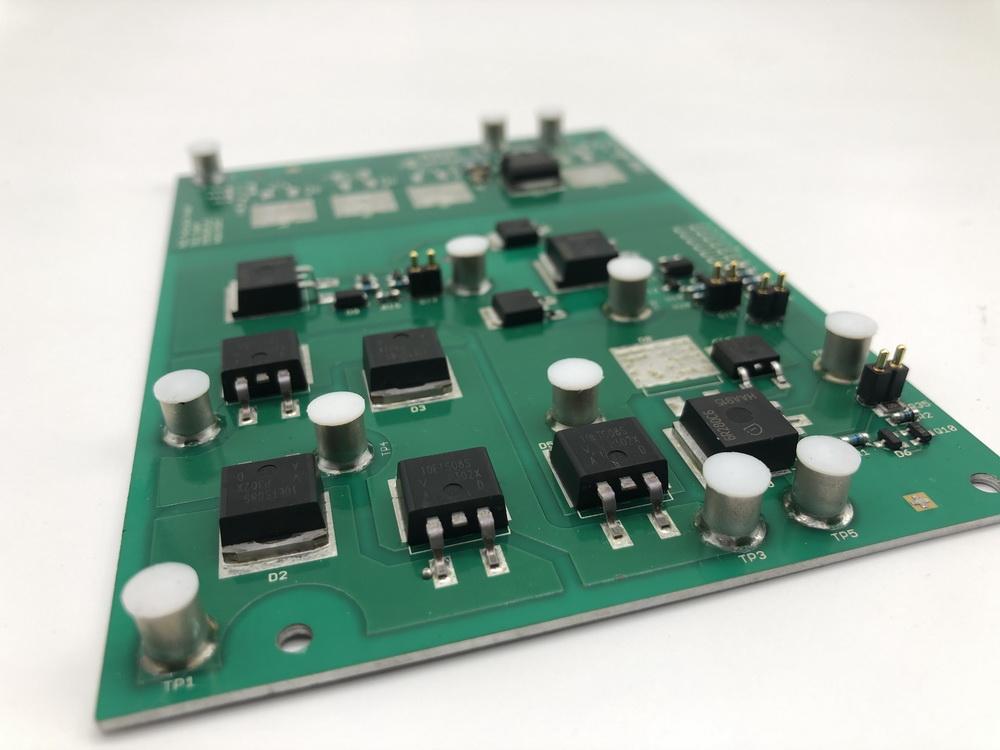

Often, a professional proof of concept can go a long way in winning the interest of investors. Turnkey PCB assembly providers ensure that you get high-quality boards without having to assemble them yourself, thus saving you valuable time. You also get from turnkey PCB manufacturers that they provide complete, professional boards with their company name and logo, adding to their look and appearance. Feel. Especially if you use surface mount components, PCB manufacturers use automated placement, which is very difficult to do when making them by hand, especially when the components are small. A high-quality final product goes a long way in inspiring confidence in your investors that you are ready to start mass production.

Helps you identify problems at the outset

The main advantage of using turnkey PCB assembly at the PCB prototyping stage is the ability to identify any problems early on. Once you share the netlist file with the PCB turnkey manufacturer, he will be able to point out errors (if any). These errors can then be corrected at the design stage itself, rather than making expensive changes once you are ready to complete the entire production run, or worse when you have already completed production and need to make changes.

Better Management

The significant advantage of PCB turnkey assembly is that you don’t have to deal with multiple suppliers. In addition to saving time, this has many other advantages. What you also have to save is the potential for miscommunication when dealing with multiple suppliers. With a PCB turnkey supplier, you may have only one point of contact, which makes the process seamless. Since delivery schedules are critical, the slightest misunderstanding between suppliers can cause the entire schedule to go awry and lead to costly consequences. With a PCB turnkey supplier, you can rest assured that the entire responsibility for timely delivery lies with them.

Help in estimating manufacturing costs: reducing costs

If there is one skill that is essential for a start-up, it is accurate financial planning. This can also be done very well through the services of a PCB turnkey provider. Early prototype costs can go a long way in estimating your future manufacturing costs. Since the unit cost is high, indicate the quantity you need and let the PCB turnkey service provider provide you with the cost. If you indicate the number of units you need per month rather than one large volume unit, the PCB manufacturer can usually quote effective costs since you may not want to do a large production run at the outset. PCB turnkey providers also offer the advantage of combining multiple small orders into one large order. They can therefore help you enjoy economies of scale that you may not be able to obtain.

Turnkey PCB assembly helps to reduce the overall cost of a PCB project. On the one hand, it helps to reduce component costs. Usually, PCB manufacturers have their supply chains and have stable and good cooperation with many suppliers, so they can always get the components at a good price. On the other hand, the entire process is done in one place, eliminating the need to transport boards or electronic components from one place to another, effectively reducing transportation costs.

Anpllo Introduces New Rapid PCB Turnkey Assembly Service for Low Volume Production in 6 Days

Hello, a China-based PCB assembly and manufacturing company specializing in prototype quantities and full turnkey PCB printed circuit board (PCB) assembly for small to medium-volume production announced a new rapid PCB turnkey assembly service today that will enable prototyping and small-volume production of PCBs to be shipped in six days.

Anpllo’s PCB design and manufacturing company, located in Shenzhen, China, has state-of-the-art automated PCB assembly equipment focused on providing the fastest turnaround time for any customer. Using world-class high-tech equipment, we supply PCBs to many customers worldwide.

Since its inception, Anpllo has provided PCB design, manufacturing and assembly services to customers in the aerospace, military, medical and commercial industries, from simple prototype PCBs to complex designs.

With this announcement, customers who become Anpllo will receive the same high-quality PCB manufacturing and assembly, but now with a shorter turnaround time.”

Anpllo offers rush turnkey PCB assembly that is proudly made in China. It uses only trusted suppliers to source parts. Orders are shipped to customers via international courier priority to ensure PCBs are delivered as quickly as possible. The company pre-checks all design files before production to ensure proper manufacturability and minimal manufacturing costs.