Content Introduction

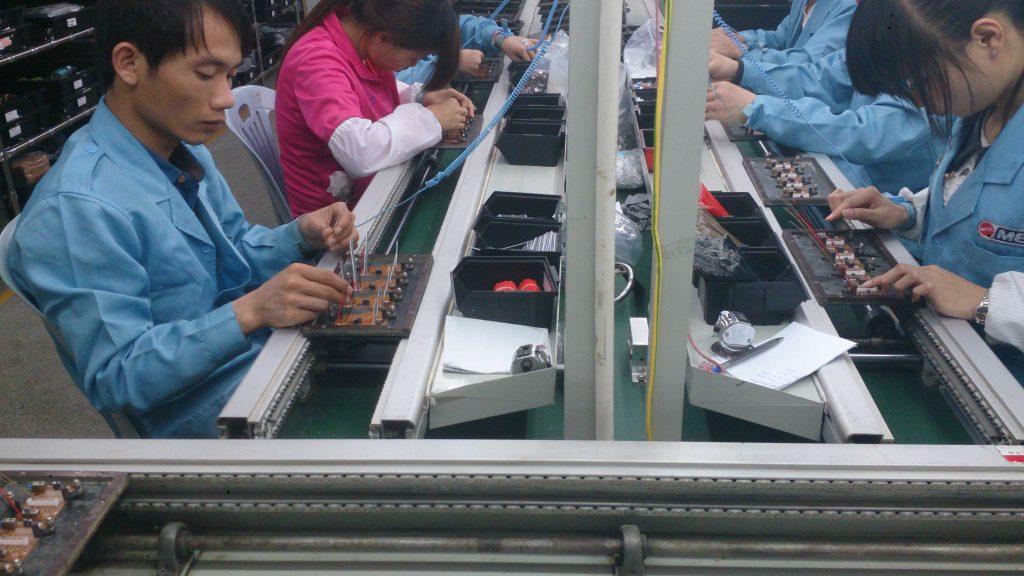

The following content is Anpllopcb’s manual assembly master, the most summarized about the PCB manual assembly points and tips.

Do you know how to hand-fit?

Recently, the company’s new products have been busy welding the board, only to find their PCB manual assembly level can be improved. Have always thought that PCB manual assembly technology is considered an excellent level. However, it turns out that I did the manual assembly of some of the more complex PCB circuit boards on the “feel good about myself” I am too proud.

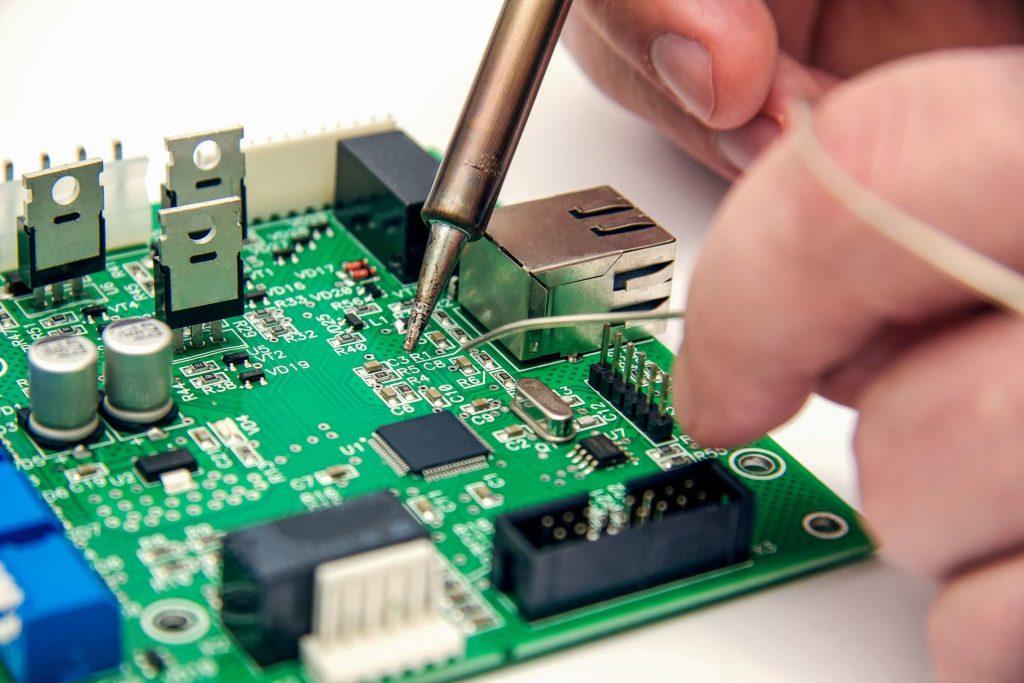

Manual assembly of SMD components on the PCB is an exact test of technical work, encountering dense chip pins smaller than the sand capacitors and resistors, false soldering, short circuits and other problems frequently and extremely difficult to find; the approach and patience requirements are very high. However, more importantly, here are some tips and details to pay attention to, some points I have ignored.

Hand-assembled PCB circuit board with 14 points and tips.

1, the commonly used wires are divided into wire classes and cable classes; wire classes have bare wire, insulated wire, electromagnetic wire, cable by the conductor, insulation, shielding, and sheathing. For different wire applications, the choice of wire is to consider electrical, environmental, and assembly process factors.

2, according to their chemical properties, insulation materials can be divided into inorganic, organic and mixed insulation materials. Insulation material performance indicators: resistivity, electric breakdown strength, breakdown voltage, mechanical strength, heat resistance, Etc.

3, commonly used soldering materials including solder and flux (flux and solder resist); soldering iron is the main tool for manual soldering. Proper selection and soldering irons are the basis for ensuring welding quality.

4, magnetic materials are divided into two categories of soft magnetic materials and hard magnetic materials; soft magnetic materials are mainly characterized by high magnetic permeability and low coercivity; under the action of the external magnetic field, magnetic induction strength can quickly reach saturation, when the external magnetic field is removed, the magnetic properties will disappear, the residual magnetism is small. The main characteristic of hard magnetic material is high coercivity; after saturation magnetization, even if the external magnetic field is removed, it will maintain long and stable magnetic properties.

5, the processing of insulated wire is divided into cutting, stripping, twisting (multi-stranded wire, tin, cleaning, printing mark and other processes). Insulated wire and shielded wire end processing.

6, with the tie wire tying methods, are wire bundling method, special wire tie buckle method, glueing bonding method, and casing set method.

7, shielded wire or coaxial cable, the same shape structure, the processing method is the same, including the processing of non-grounding wire end, grounding wire end processing and wire end tying processing.

8, the main components of lead forming special mould forming, special equipment forming and manual use of pointed pliers for simple processing and other methods. Among them, mould manual forming is more commonly used.

9, components of the lead in the dip tin before should be 2 ~ 5 mm from the device’s root to remove the oxide layer. Removing the oxide layer to the dip in time generally does not exceed one hour.

10, components can be divided into vertical inserts, horizontal inserts, inverted inserts, and embedded in the form of inserts.

11, manual welding, often using the five-step operation method. Manual welding know-how.

① Surface treatment should be performed on the soldered parts first.

②The component leads should be tinned.

③ Do not use too much flux.

④The tip of the soldering iron should be rubbed frequently.

⑤ To the solder tray and component heating to have solder bridge.

When soldering the metalized hole on the double-layer circuit board, let the solder wet the pad and let the hole also wet fill, so the heating time for the metalized hole should be slightly longer.

11, between the wire and terminal welding, has three basic forms: around the welding, hook welding and lap welding.

13, manual desoldering methods and techniques.

Available resistors, capacitors, diodes, transistors and other components of the pin are not much; these components can be directly touch welding with a soldering iron. When the need to remove more than one lead component or although the number of lead components but the lead is relatively hard, you can use homemade special tools to desolder and make a special soldering iron head.

14, bonding, also known as glue, the formation of a good bonding of the three elements are the choice of suitable adhesives, handling the bonding surface and the choice of the correct curing method.

Write at the end

Finally, I would like to thank the company’s engineers for daring to give me the latest product samples; it seems that I can only find my shortcomings and improve under strict requirements. Although I have been exposed to many new components and more complex printed circuits, there are still more things to discover in the colourful world of electronics.